Method for preparing carvone

A technology of carvone and carvone oxime, which is applied in the field of preparation of carvone, and can solve problems such as low single-step yield, complex products, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

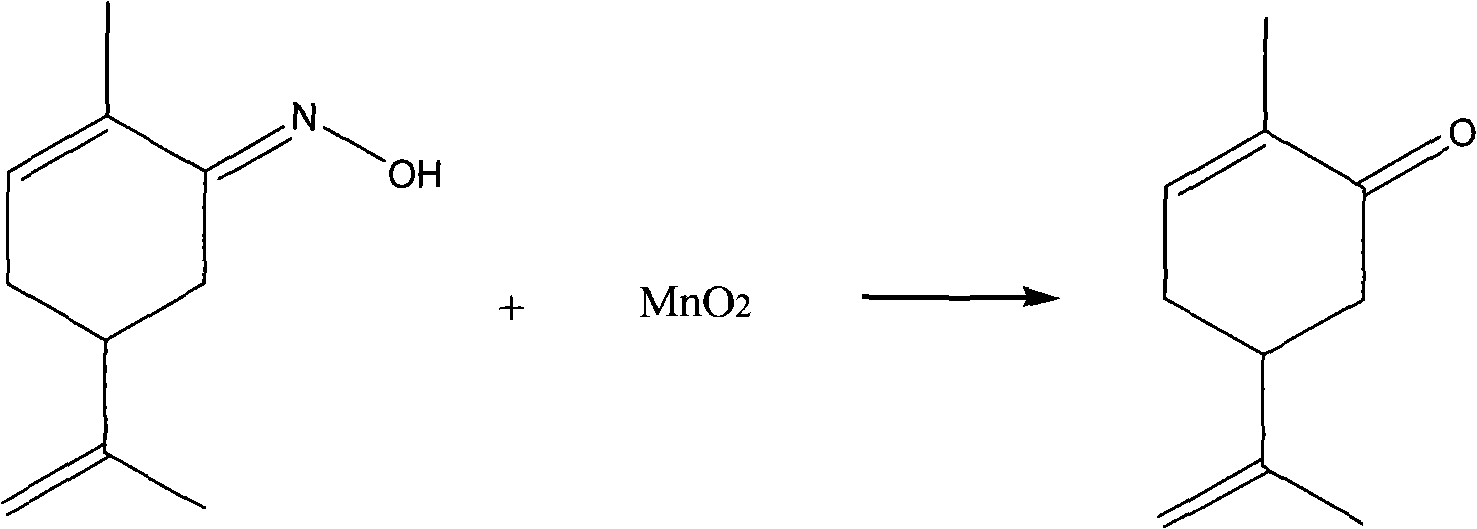

[0006] The invention discloses a preparation method of carvone. Carvone oxime is oxidized by heating and refluxing with activated or fresh manganese dioxide, and the oxidation product is carvone. In this reaction, the amount of manganese dioxide used is about 1 to 15 times the molar equivalent of carvone oxime, and the required temperature is about 0°C to 100°C. The reaction formula is as follows:

[0007]

[0008] Among them, manganese dioxide can be prepared by potassium permanganate and manganese sulfate in aqueous solution. Commercially available manganese dioxide can be made into activated manganese dioxide under the action of an activator. Wherein, the activator used can be organic carboxylic acids such as acetic acid, propionic acid, butyric acid, isobutyric acid or oxalic acid, or inorganic acids such as dilute sulfuric acid, dilute hydrochloric acid, dilute phosphoric acid or dilute nitric acid. The method of activating manganese dioxide is illustrated as follow...

example 1

[0009] Example 1: Put 800g of manganese dioxide into a reaction kettle, add 2L of 5% dilute sulfuric acid, stir for 10 minutes, filter, wash with water until nearly neutral, filter and dry, and heat up to 120-125 degrees in an oven to dry 4 Hours, cooled and ground into powder form is activated manganese dioxide.

example 2

[0010] Example 2: Put 800g of manganese dioxide into the reaction kettle, add 2L of 5% dilute nitric acid, stir for 10 minutes, filter, wash with water until nearly neutral, filter and dry, and heat up to 120-125 degrees in an oven to dry 4 Hours, cooled and ground into powder form is activated manganese dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com