Biodegradable material poly(hexanedioic acid-para-phthalic acid-butanediol ester) foaming particles preparation method

A technology of terephthalic acid and polyadipic acid, which is applied in the field of biodegradable polymer foaming materials, can solve the problems of unfavorable industrial production and long production cycle, and achieve the benefits of industrial production, short production cycle and promotion of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

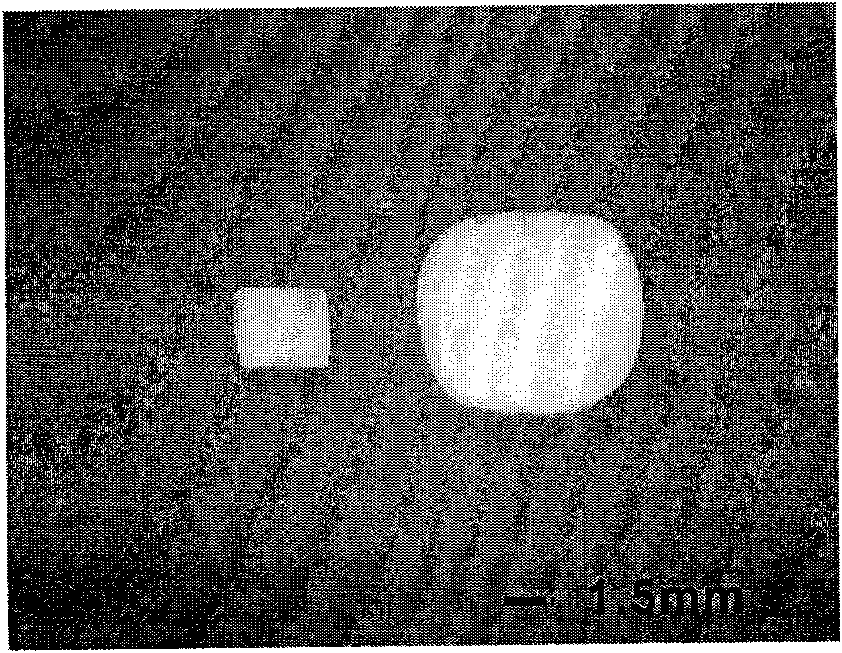

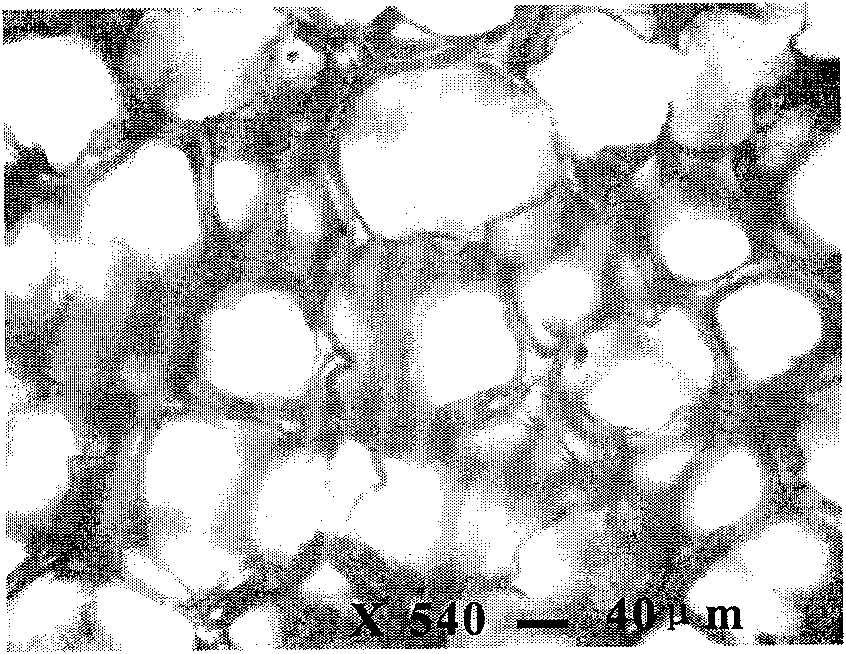

[0030] Put pure PBAT particles in a container, and ensure that the total volume of the particles does not exceed 1 / 25 of the volume of the container, so that the particles have enough space for foaming. When the container reaches the set temperature of 136°C, it is filled with high pressure N of 20MPa. 2 , keep the pressure at a constant temperature for 10min, and then release the pressure to normal pressure at a speed of 10MPa / s. The foamed material was removed and subjected to optical microscopy analysis and density measurements. The cell diameter of the PBAT expanded particles is 80 μm and the density is 0.15 g / cm 3 , the foaming ratio is 8.2 times. Particle size comparison before and after particle foaming figure 1 As shown, the optical microscope photo after foaming is as follows figure 2 shown.

Embodiment 2

[0032] Put pure PBAT particles in a container, and ensure that the total volume of the particles does not exceed 1 / 25 of the volume of the container, so that the particles have enough space for foaming. When the container reaches the set temperature of 130°C, it is filled with high pressure N of 15MPa. 2 , maintain the pressure at a constant temperature for 20min, and then release the pressure to normal pressure at a speed of 20MPa / s. The foamed material was removed and subjected to optical microscopy analysis and density measurements. The cell diameter of the PBAT expanded particles is 45 μm and the density is 0.32 g / cm 3 , the foaming ratio is 3.8 times.

Embodiment 3

[0034] Put pure PBAT particles in a container, and ensure that the total volume of the particles does not exceed 1 / 25 of the volume of the container, so that the particles have enough space for foaming. When the container reaches the set temperature of 138°C, it is filled with high pressure N of 20MPa. 2 , keep the pressure at a constant temperature for 15min, and then release the pressure to normal pressure at a speed of 10MPa / s. The foamed material was removed and subjected to optical microscopy analysis and density measurements. The cell diameter of the PBAT expanded particles is 90 μm and the density is 0.14 g / cm 3 , the foaming ratio is 8.8 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Cell diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com