Ionic polymer composite material for brake and preparation method thereof

A technology of ionic polymers and composite materials, which is applied in the field of ionic polymer composite materials and its preparation, can solve the problems of affecting the service life of actuators, increasing the braking strain of actuators, and poor electro-mechanical coupling effects. Achieve the effects of large ion exchange capacity, enhanced grip strength, and large strain displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

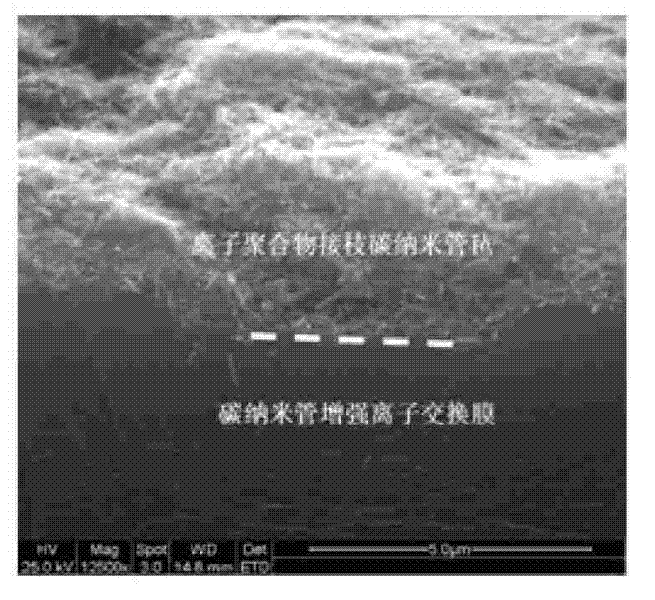

[0032] Disperse 10 mg of carbon nanotubes in 20 ml of water, oscillate ultrasonically for 15 min, then add 100 mg of sodium styrene sulfonate to the dispersion, then add 0.5 mg of ammonium persulfate under nitrogen protection, and heat up to 70°C for 12 h under reflux. After the reaction is completed, filter through a microporous membrane, wash with water for three times, and dry to obtain the ion polymer-grafted carbon nanotube.

[0033] Under ultrasonic vibration for 15 min, 5 mg of ionomer-grafted carbon nanotubes were ultrasonically dissolved in 10 ml of water. After filtering through a microporous membrane, washing with water for 3 times, and drying, the membrane was peeled off to obtain an ionomer-grafted carbon nanotube felt.

[0034] Dissolve 100mg of acrylic acid and 900mg of sodium styrene sulfonate in 99ml of water, then add 5mg of ammonium persulfate under nitrogen protection, and heat up to 70°C for 12h under reflux. After the reaction is completed, it is precipi...

example 2

[0037] Disperse 10mg of carbon nanotubes in 20ml of water, ultrasonically oscillate for 15min, then add 10mg of sodium styrene sulfonate and 90mg of acrylic acid into the dispersion, then add 0.5mg of ammonium persulfate under nitrogen protection, and heat up to 70°C Reflux for 12h. After the reaction is completed, filter through a microporous membrane, wash with water for three times, and dry to obtain the ion polymer-grafted carbon nanotube.

[0038] Under ultrasonic vibration for 15 min, 5 mg of ionomer-grafted carbon nanotubes were ultrasonically dissolved in 10 ml of water. After filtering through a microporous membrane, washing with water for 3 times, and drying, the membrane was peeled off to obtain an ionomer-grafted carbon nanotube felt.

[0039]Dissolve 100mg of acrylic acid and 900mg of sodium styrene sulfonate in 99ml of water, then add 5mg of ammonium persulfate under nitrogen protection, and heat up to 70°C for 12h under reflux. After the reaction is completed,...

example 3

[0042] Take 100mg of carbon nanotubes and ultrasonically disperse them in 30ml of water, ultrasonicate for 30min, then add 3g of acrylic acid and 3g of sodium styrene sulfonate to it, then add 60mg of potassium persulfate under nitrogen protection and heat up to 80°C for 16h under reflux. After the reaction is completed, filter through a microporous membrane, wash with water three times, and dry to obtain the ion polymer-grafted carbon nanotube.

[0043] Disperse 60mg of grafted carbon nanotubes in 30ml of water, and sonicate for 45min. Filtrate through a microporous membrane, wash with water for 3 times, dry and peel off the membrane to obtain the ionic polymer grafted carbon nanotube felt.

[0044] 3g of acrylic acid and 3g of sodium styrene sulfonate were dissolved in 30ml of water, then 60mg of potassium persulfate was added under the protection of nitrogen and the temperature was raised to 80°C and refluxed for 16h. After the reaction is completed, poly(sodium styrene su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com