Method for improving accuracy of control of automatic sun track following of heliostat

A sun trajectory and automatic tracking technology, which is applied to solar collector controllers, solar collectors in specific environments, solar thermal devices, etc., can solve problems such as reduced accuracy, affecting control accuracy, and tracking deviation of heliostats. Achieve the effects of improving power generation efficiency, improving control accuracy, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

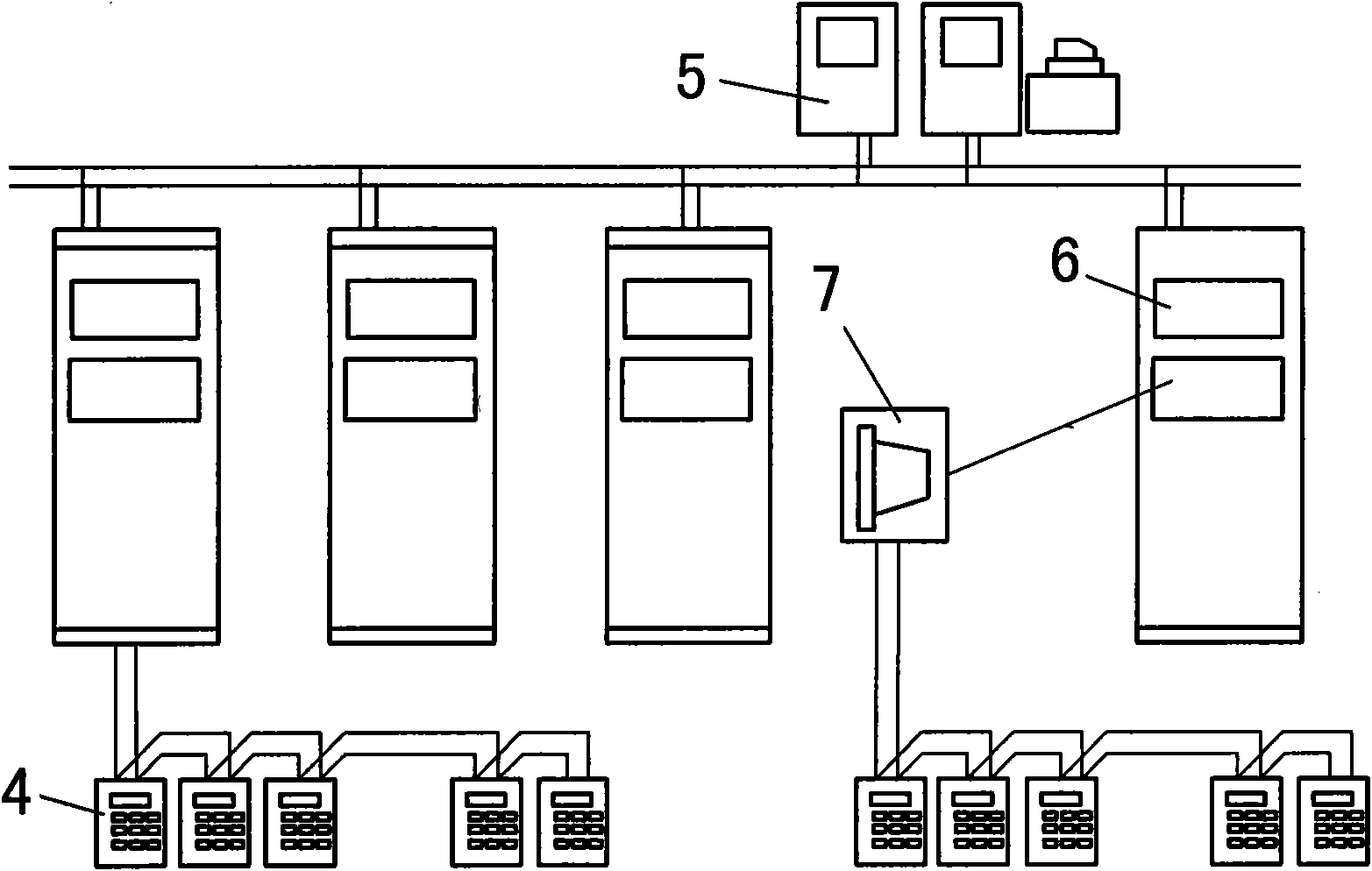

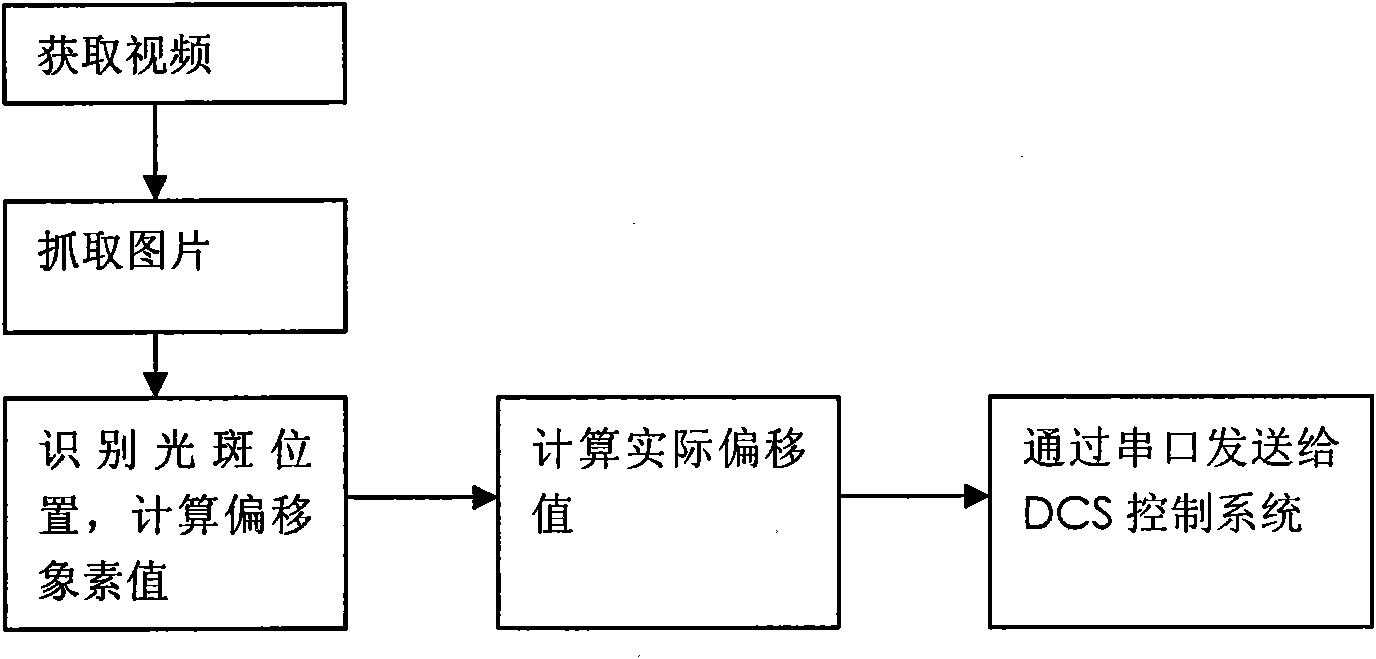

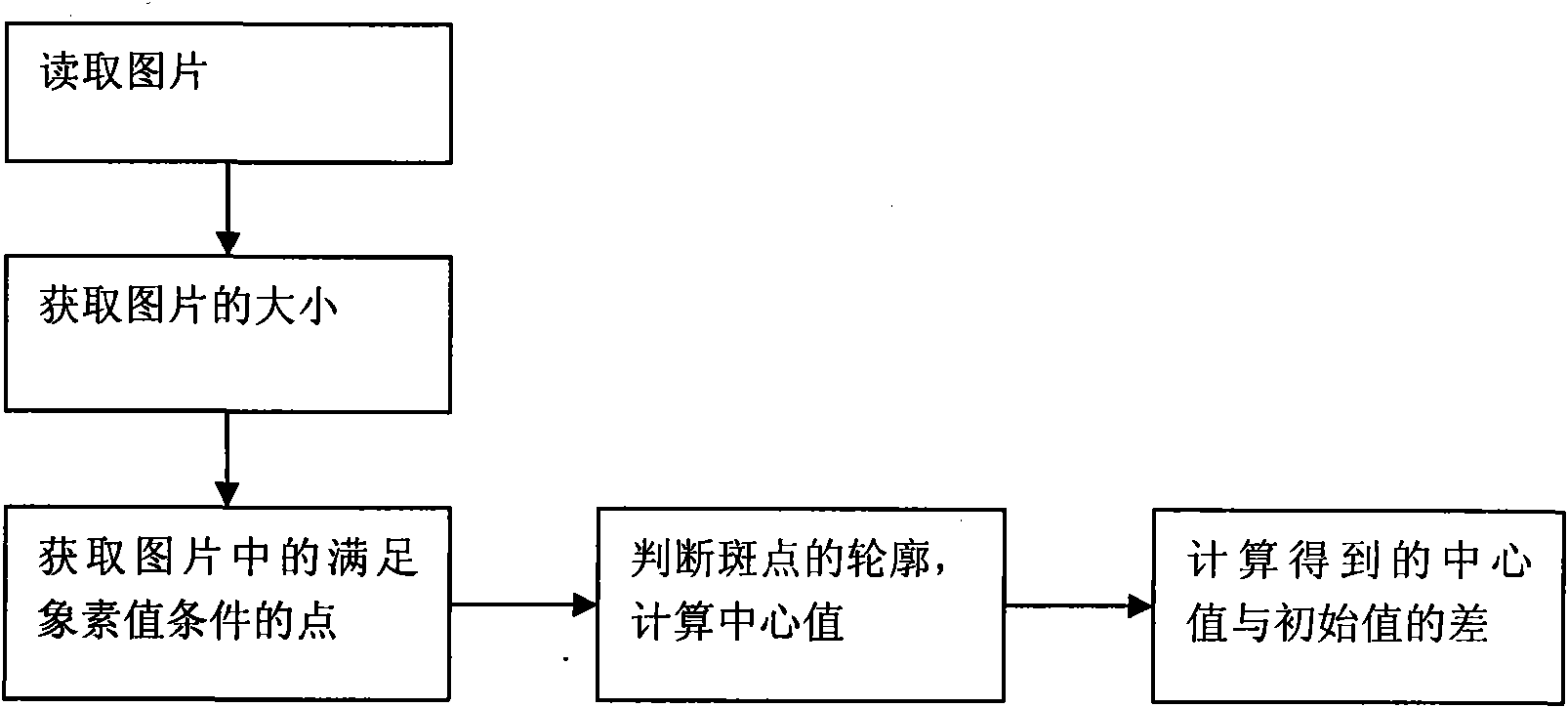

[0026] Example. Choose a heliostat, and the transmission actuator of the heliostat is Schneider LXM intelligent servo driver and Schneider BSH1402P32F1A servo motor. The data transmission is carried out through the system’s MODBUS to CAN protocol conversion module and the system’s DPU controller. According to the solar angle motion formula, the controller calculates the real-time reflection of sunlight from the mirror surface to the heat absorber’s travel distance, and then the servo driver feeds back the travel position value of the heliostat through the protocol conversion module to the DPU controller to form a closed-loop control and complete the fixed position. The sun mirror automatically and accurately tracks the sun's trajectory and reflects sunlight to the heat sink on the top of the tower. Such as figure 1 As shown, the intelligent measurement and control device 4, the operator station 5, the DPU controller 6 and the communication protocol conversion module 7 constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com