Method for measuring liquid capacity of pipeline based on ultrasonic guided wave technology

A technology of ultrasonic guided wave and measurement method, applied in the direction of liquid/fluid solid measurement, measurement flow/mass flow, measurement device, etc. state and other problems, to achieve the effect of high measurement reliability, low labor intensity and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Provide the embodiment that following numerical simulation obtains in conjunction with the content of the inventive method:

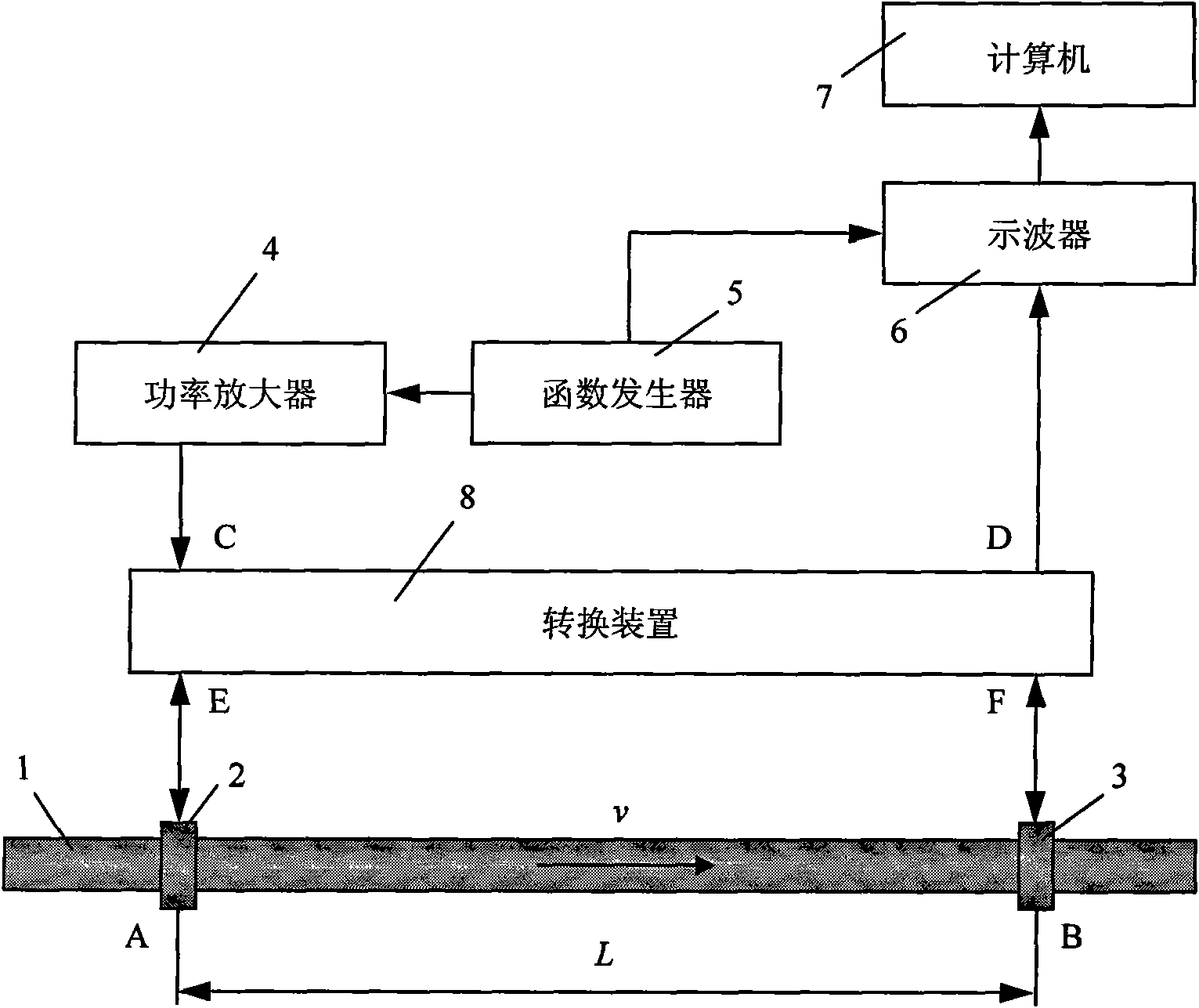

[0029] (1) The first sensor group (ring) 2 and the second sensor group (ring) 3 distributed symmetrically along the axis of the liquid-filled pipeline are installed in the same water-filled steel pipe 1 with a distance L between them. The inner radius r of the water-filled steel pipe in this embodiment 1 = 4mm and outer radius r 2 = 5mm;

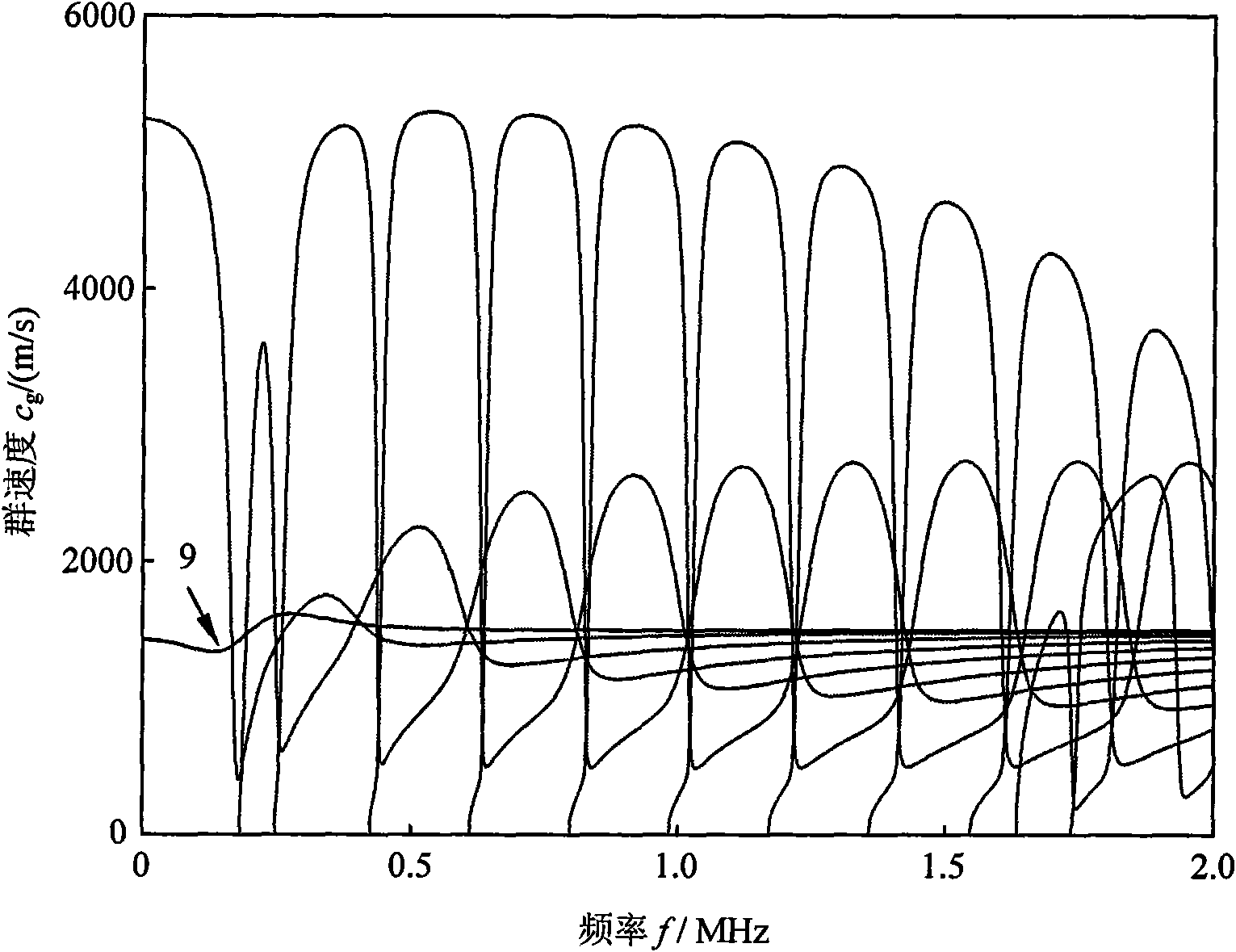

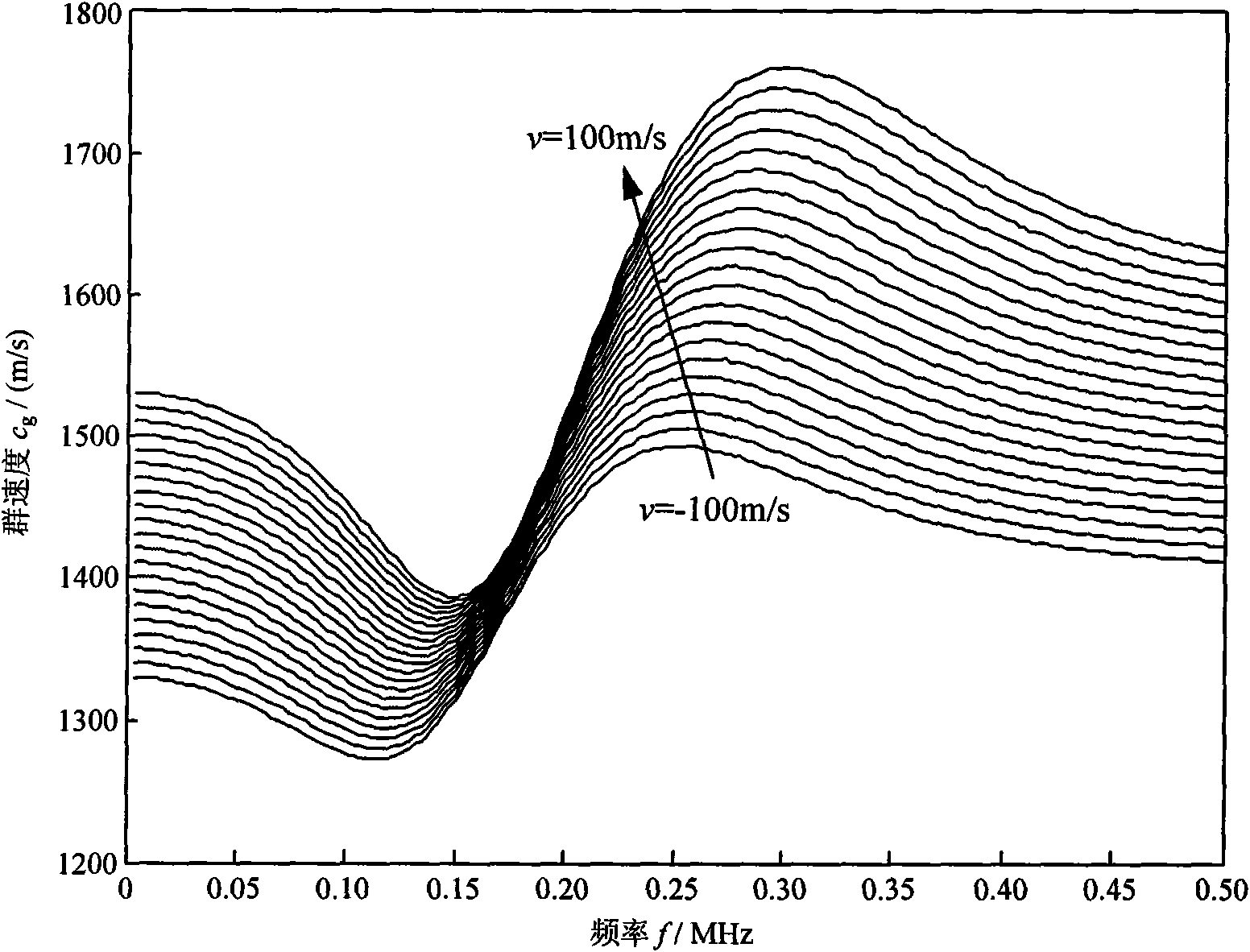

[0030] (2) The theoretical analysis obtains the phase velocity c of the longitudinal mode of the ultrasonic guided wave in the water-filled steel pipe considering the flow velocity v of the water in the pipe p dispersion equation | D | = D 11 D 12 D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com