Accelerating reactor for accelerating ageing of performance of plastic film by sludge composting method

A plastic film and reactor technology, applied in the field of accelerated reactors, can solve problems such as long experimental period, and achieve the effects of improving research period, accelerating aging process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

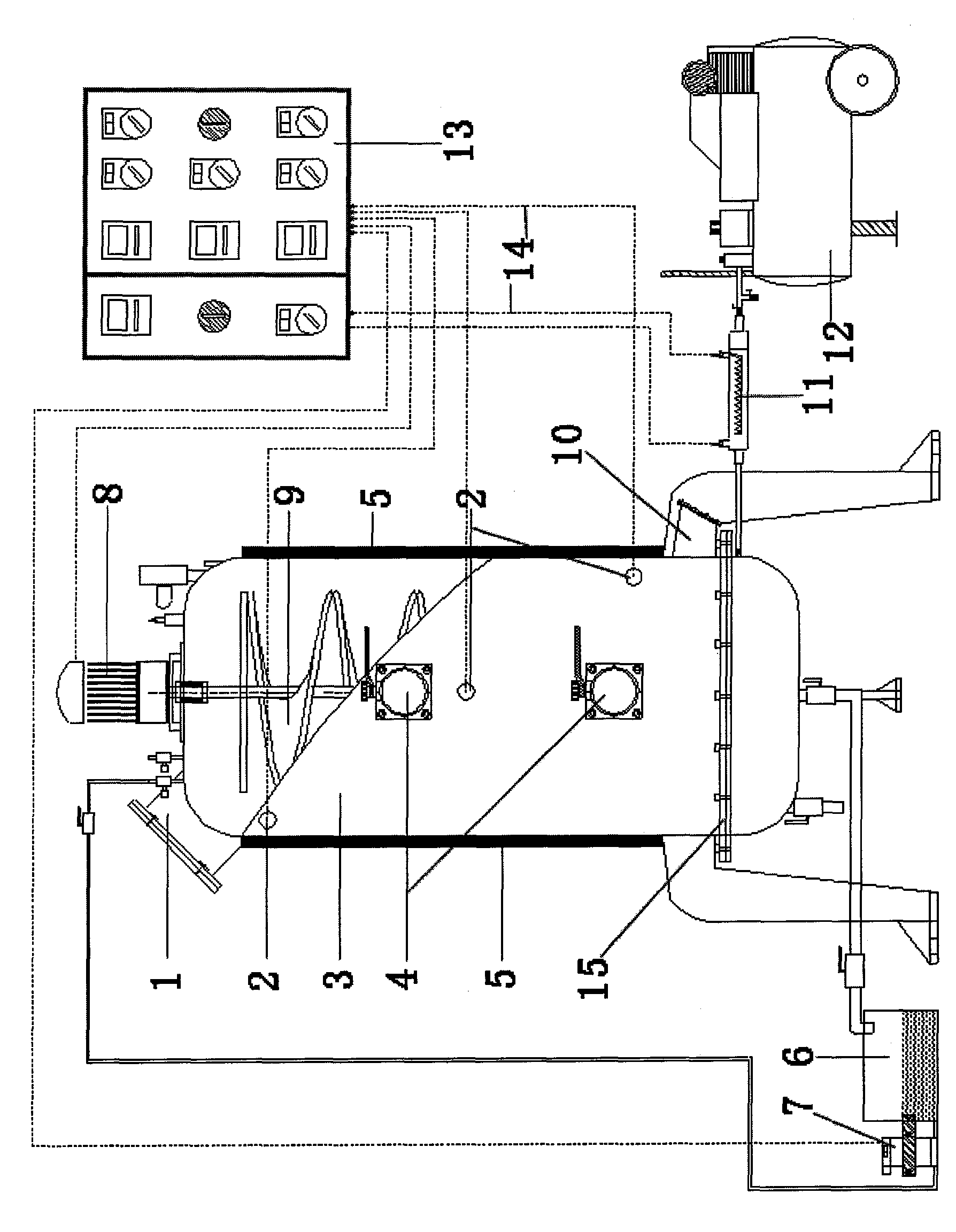

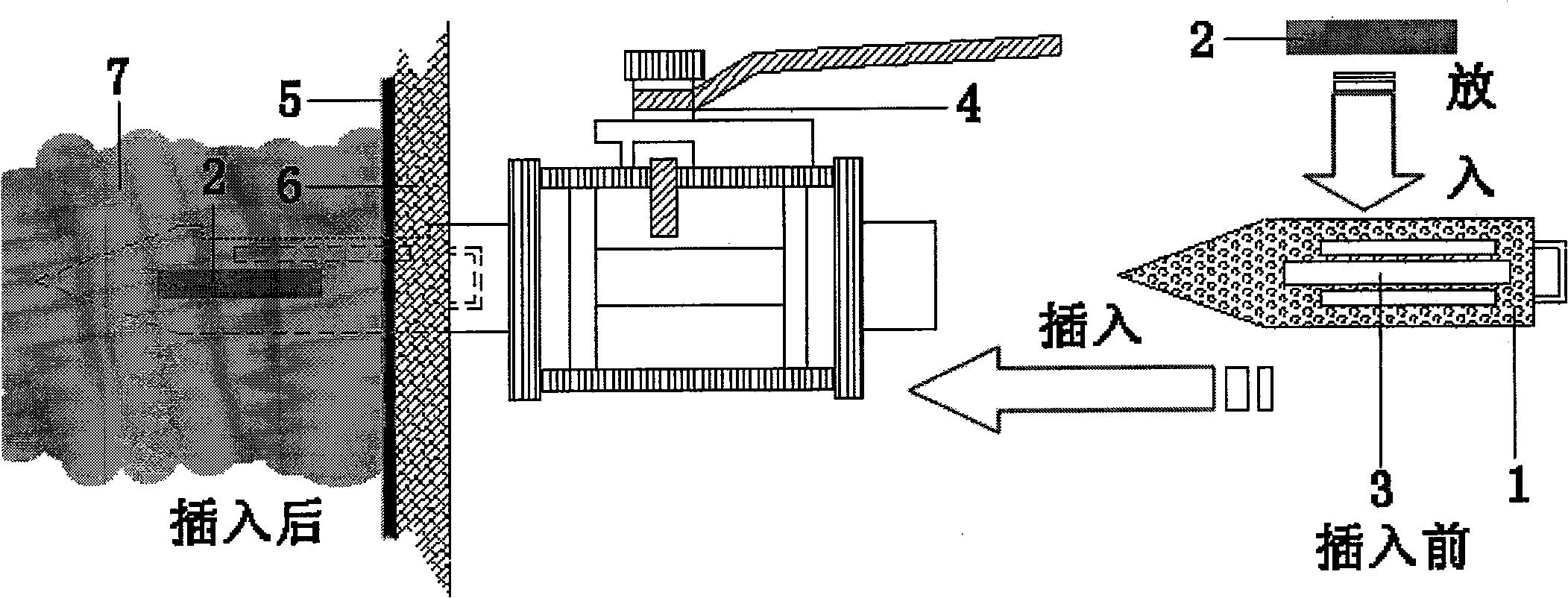

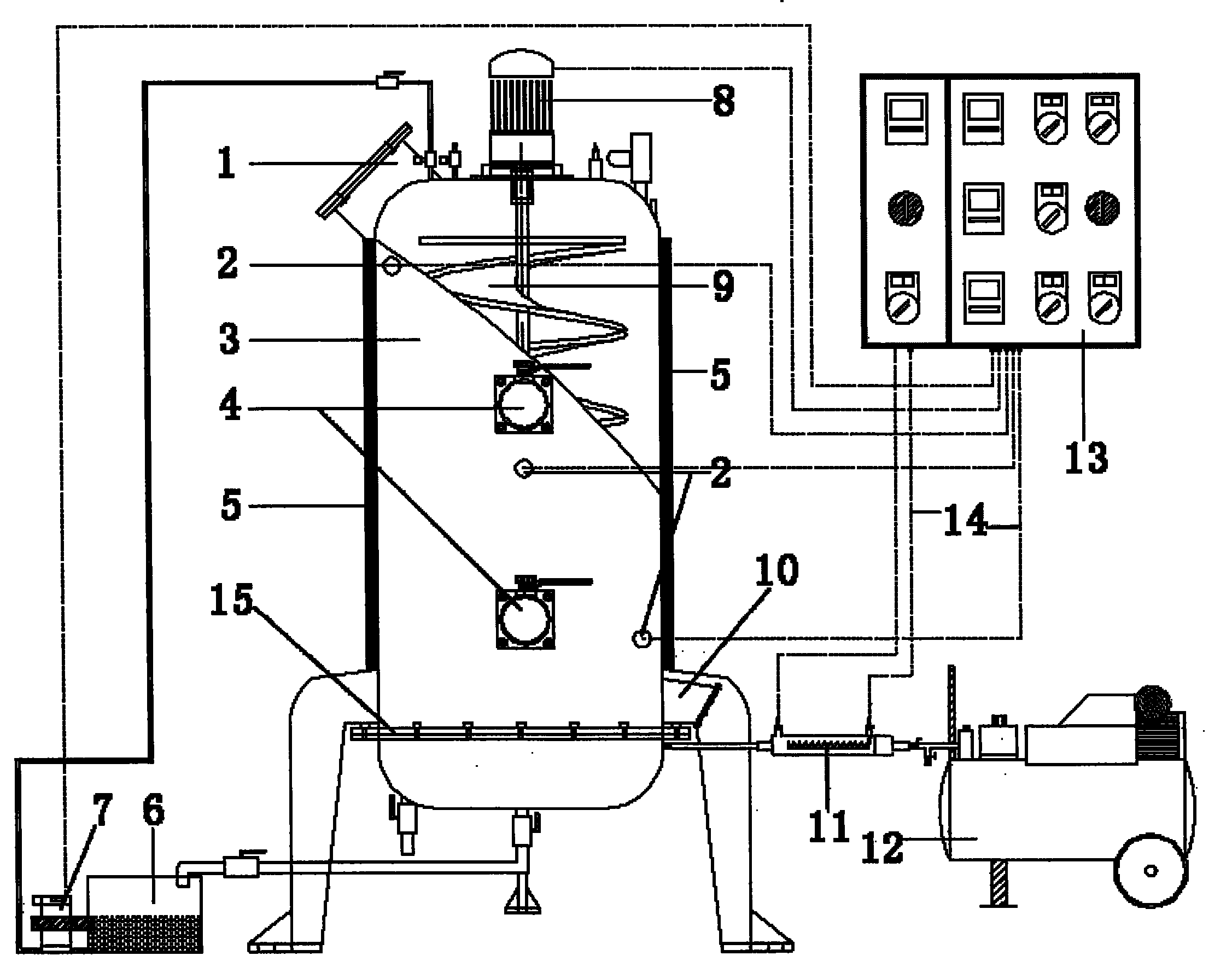

Method used

Image

Examples

Embodiment 1

[0028] Study on the Degradation Performance of PE / CaO Composite Materials under Reactor Aerobic Composting Conditions

[0029] According to the structure of the present invention, an accelerated reactor for accelerating the performance aging of plastic films by utilizing sludge composting is produced. Take 100kg of fresh sludge with an initial moisture content of 83.55%, add 1kg of sodium polyacrylate and 15kg of sawdust in the weight ratio of sludge: sodium polyacrylate: sawdust=100:1:15, and mix uniformly to form a sludge mixture .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com