Ceramic metal composite foam material and preparation method thereof

A technology of ceramic metal and composite foam, applied in the field of metal composite materials, can solve the problems of poor material formability, poor strengthening effect, easy thermal cracking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

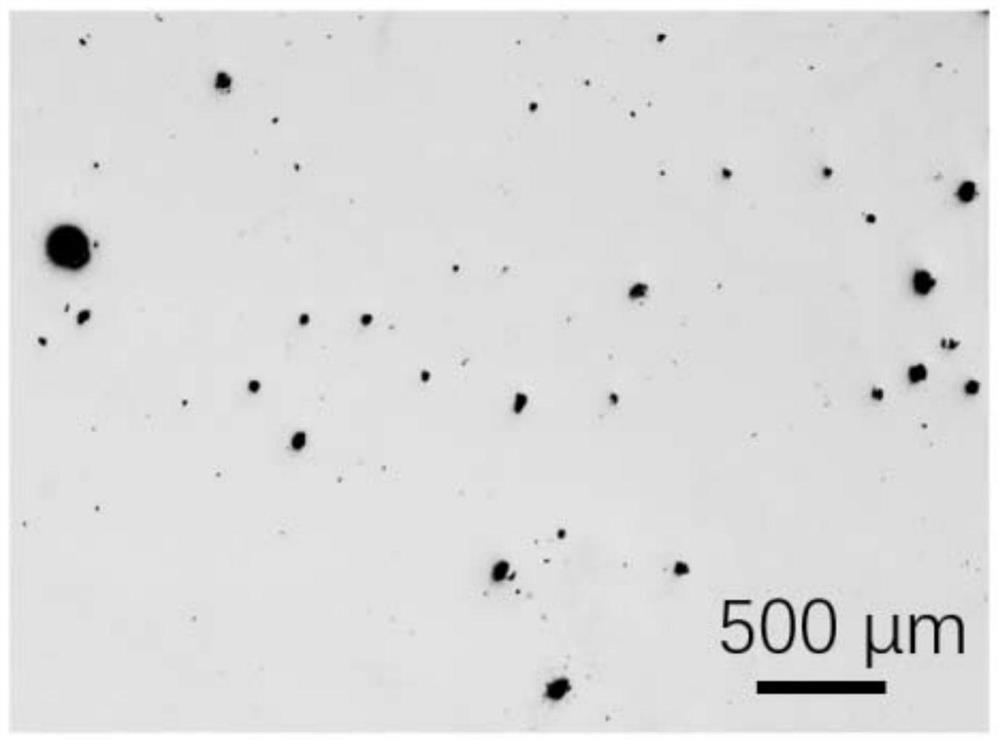

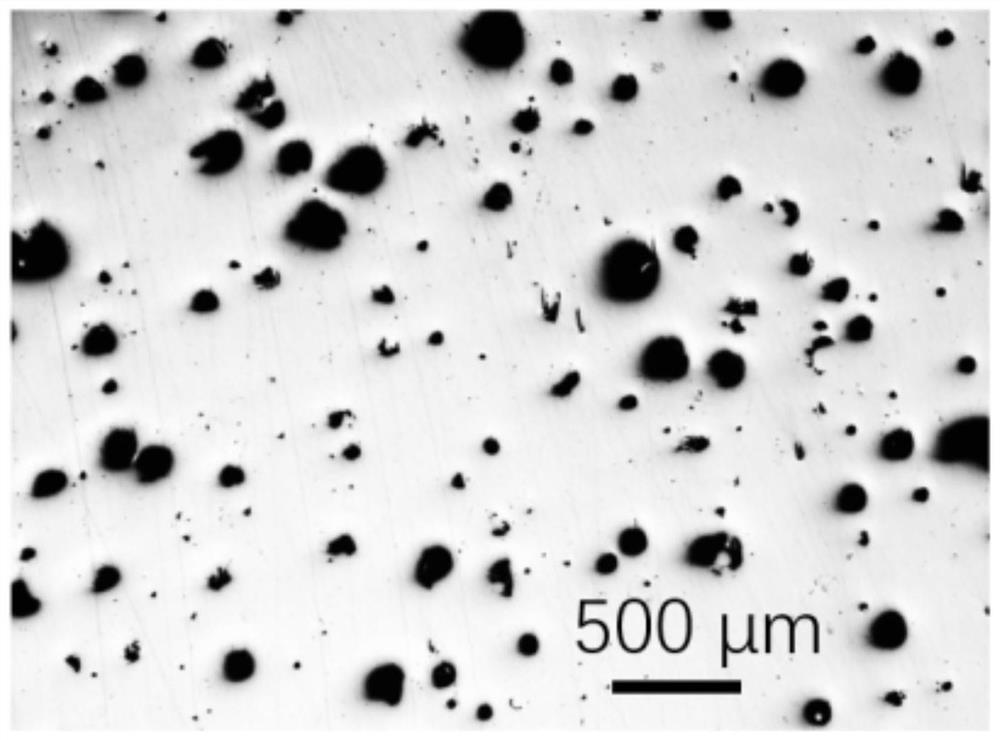

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a method for preparing a ceramic-metal composite foam material, comprising the following steps:

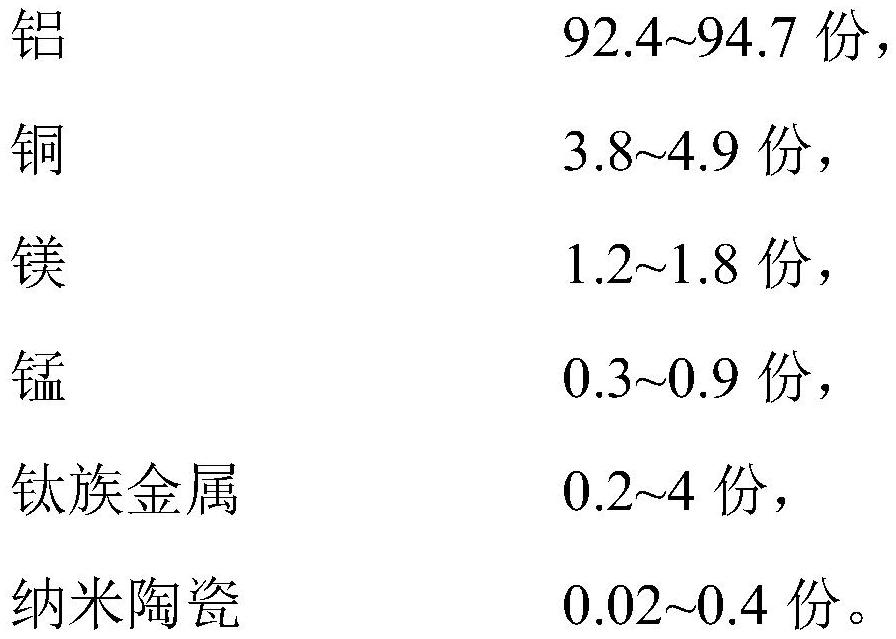

[0032] S10. Obtain 92.4-94.7 parts of aluminum powder, 3.8-4.9 parts of copper powder, 1.2-1.8 parts of magnesium powder and 0.3-0.9 parts of manganese powder, mix and melt the aluminum powder, copper powder, magnesium powder and manganese powder to make powder , to obtain Al-Cu-Mg-Mn alloy powder;

[0033] S20. Obtain 0.2-4 parts of titanium group metal powder and 0.02-0.4 parts of nano-ceramic powder, assemble the titanium-group metal powder and the nano-ceramic powder to obtain a composite powder;

[0034] S30. Mixing the aluminum-copper-magnesium-manganese alloy powder and the composite powder and then drying to obtain a ceramic-metal composite powder;

[0035] S40. After performing additive forming treatment on the ceramic composite powder, performing aging treatment to obtain a ceramic-metal composite foam material.

...

Embodiment 1

[0057] A ceramic-metal composite foam material, comprising the following preparation steps:

[0058] ①According to the mass ratio of aluminum powder: 94.1%, copper powder: 3.9%, magnesium powder: 1.7%, manganese powder: 0.3%, the raw materials are melted in a vacuum induction melting furnace at 700°C, and then gas atomization is carried out after melting Spherical powder is obtained from the powder, and the aluminum-copper-magnesium-manganese alloy powder with a particle size of less than 200 mesh is obtained through a powder collection device and a sieving device.

[0059] ②Select titanium powder with a particle size of less than 200 mesh, and assemble it with nano-ceramic powder at a mass ratio of 10:1 to form a composite powder;

[0060] ③Turn over, invert, and shake the Al-Cu-Mg-Mn alloy powder and 2 parts by weight of the composite powder in a three-dimensional rocking powder mixer for two hours to make them evenly mixed, then place them in a vacuum dryer at 80°C for 4 H...

Embodiment 2

[0064] A ceramic-metal composite foam material, comprising the following preparation steps:

[0065] ①According to the mass ratio of aluminum powder: 94.1%, copper powder: 3.9%, magnesium powder: 1.7%, manganese powder: 0.3%, the raw materials are melted in a vacuum induction melting furnace at 700°C, and then gas atomization is carried out after melting Spherical powder is obtained from the powder, and the aluminum-copper-magnesium-manganese alloy powder with a particle size of less than 200 mesh is obtained through a powder collection device and a sieving device.

[0066] ②Select titanium powder with a particle size of less than 200 mesh, and assemble it with nano-ceramic powder at a mass ratio of 10:1 to form a composite powder;

[0067] ③Turn over, invert, and shake the Al-Cu-Mg-Mn alloy powder and 2 parts by weight of the composite powder in a three-dimensional rocking powder mixer for two hours to make them evenly mixed, then place them in a vacuum dryer at 80°C for 5 H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com