High power factor cascade stage speed regulating device of phase-shifting chopped waves

A high power factor, cascaded speed regulation technology, applied in the direction of electrical components, control systems, AC motor control, etc., can solve the problems of device reliability reduction, overcurrent fault, uncontrollable rotor rectification current, etc., to achieve power factor and Effect of Reliability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

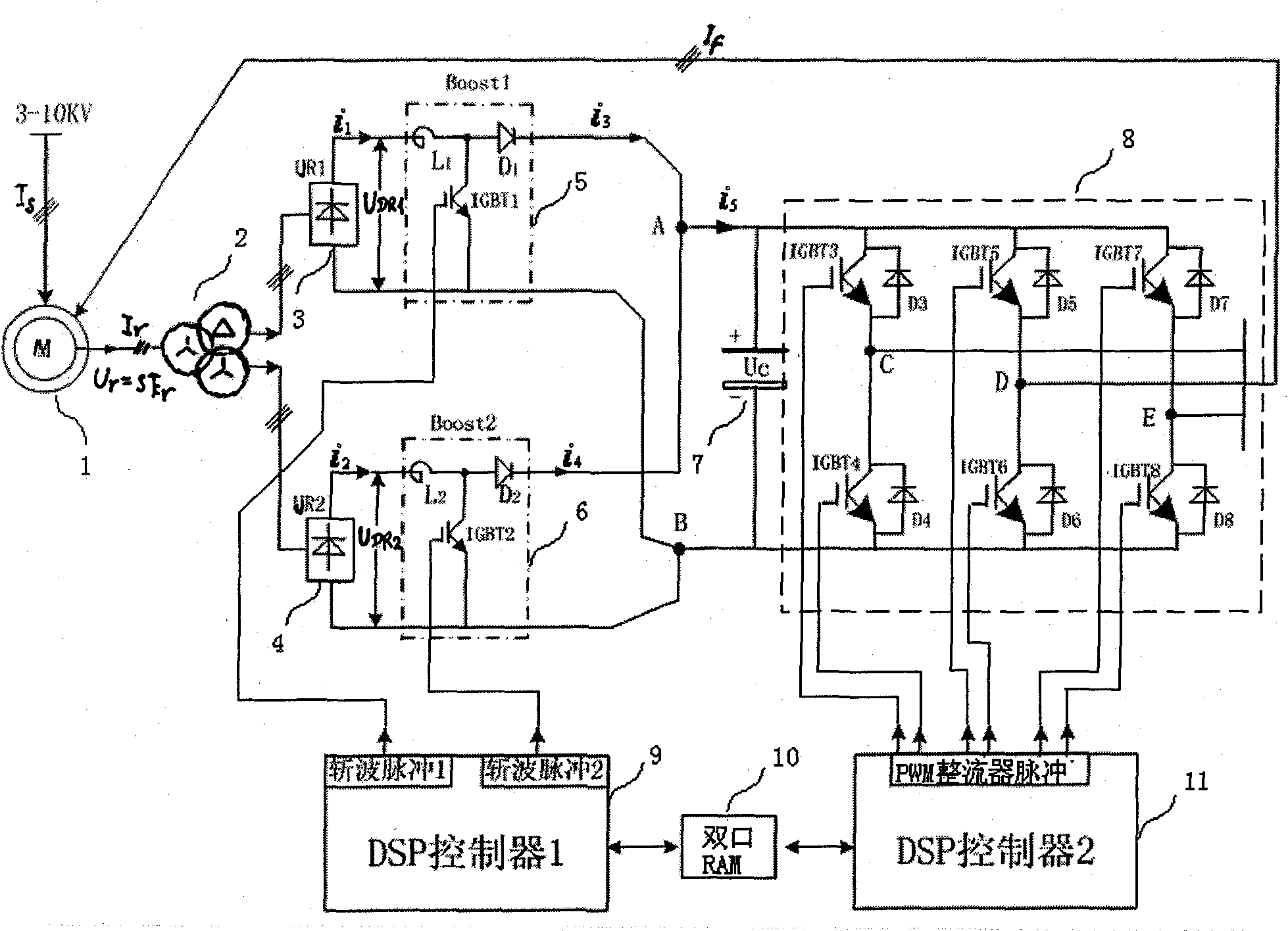

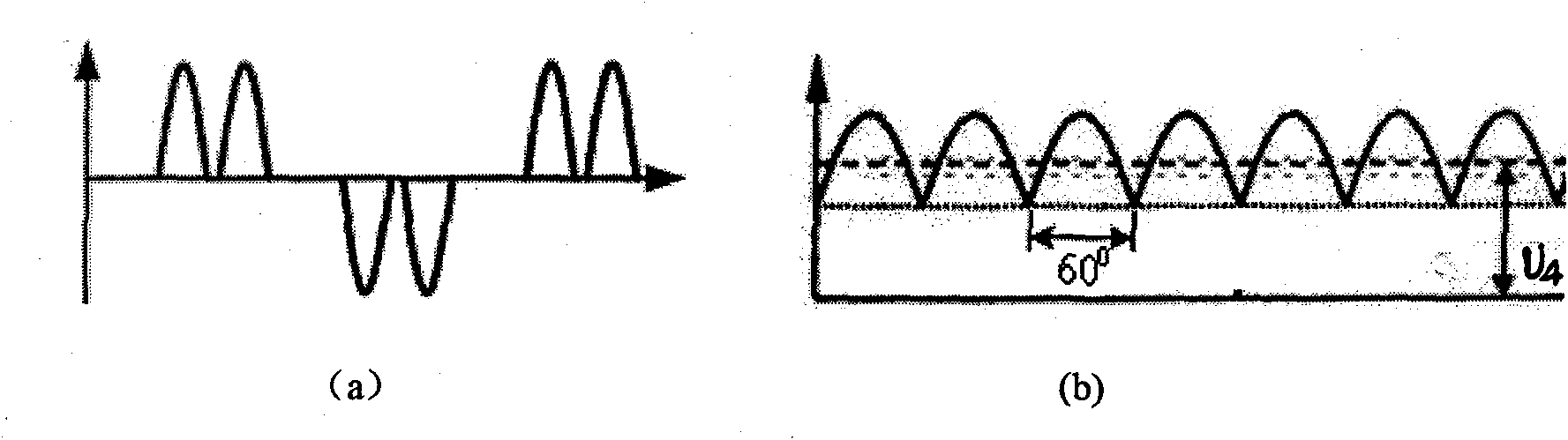

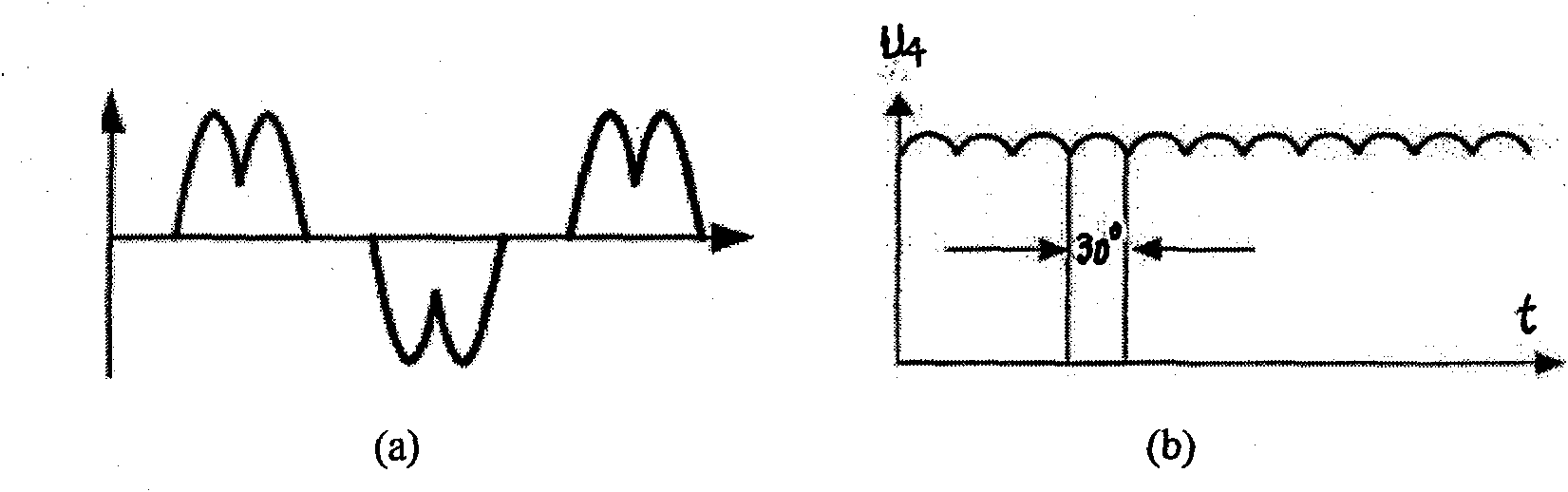

[0014] The principle of high power factor cascade speed control device based on phase-shift chopping is as follows: figure 1 shown. figure 1 It consists of two parts, the main circuit and the control circuit. The main circuit is composed of two parts, the inner feed motor 1 and the cascade speed control device. Wherein the inner feed motor is divided into three parts again, the stator winding (current flowing through is I s ), the rotor winding (the current flowing through is I r ), adjust the winding (the current flowing through is I f ); the cascade speed control device is composed of a rectification part (12-pulse rectification), a chopping part (phase-shifting chopping), and an inverter part (PWM rectifier). Among them, the rectifier part and the rotor winding of the inner-fed motor 1 are connected through the Y / Y / Δ transformer 2, and the difference between the secondary side coils is 30°. The output is composed of two rectifiers 3 and 4 to form a 12-pulse rectificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com