Novel thermal forming method of high-strength steel plate stamping part

A high-strength steel plate and hot forming technology, which is applied in the field of hot stamping forming, can solve problems such as plate oxidation, achieve good surface quality, improve service life, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

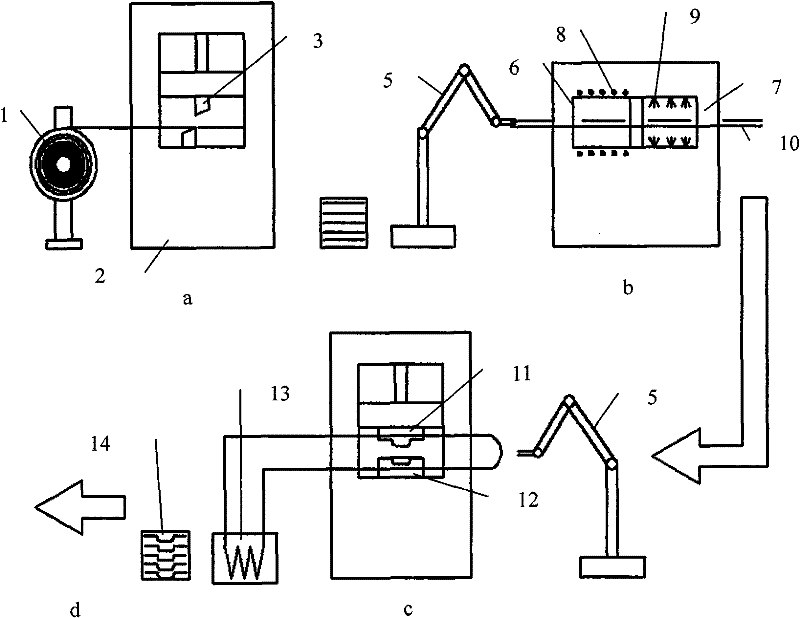

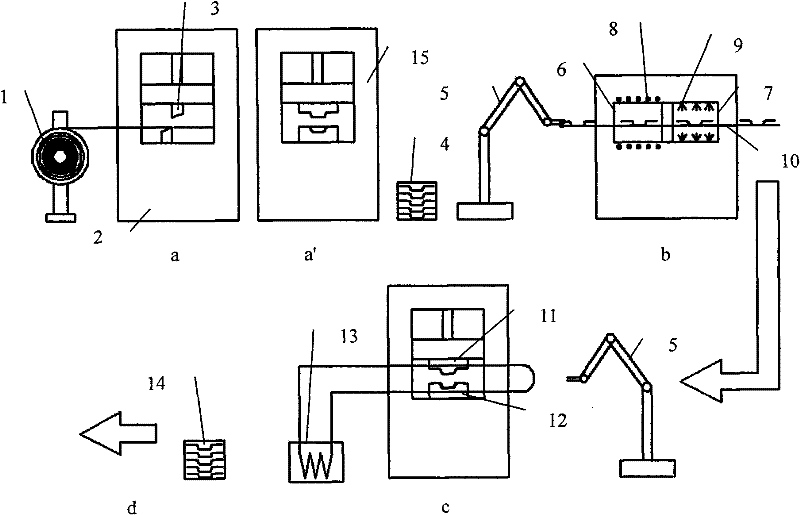

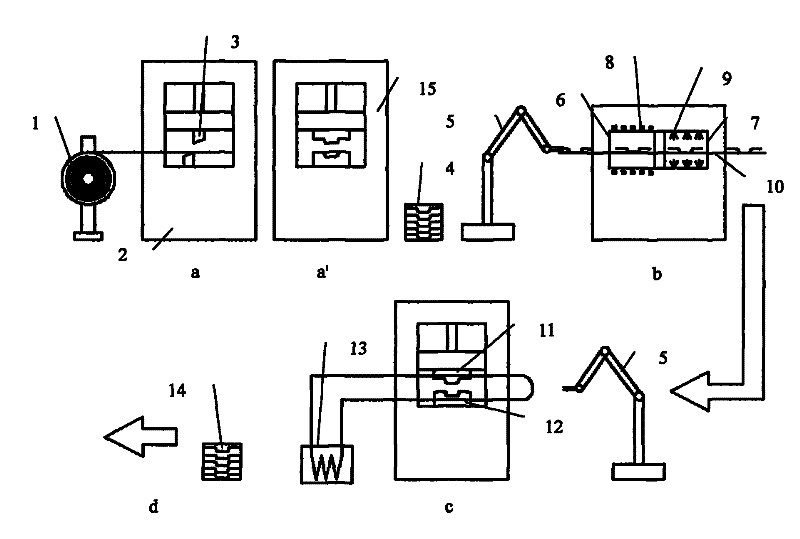

[0019] The content of the present invention and its specific implementation are further described below in conjunction with the examples shown in the accompanying drawings.

[0020] figure 1 The direct forming process is shown. The high-strength steel plate 1 is first blanked on the blanking press 2, and then transferred to a heating furnace 6 with a gas protective atmosphere by a manipulator 5 to heat the plate to a temperature above the recrystallization temperature, and keep it for a period of time. The plate is completely austenitized, and then transferred to the preliminary cooling chamber 7 without contact with air. There is still a gas shielding atmosphere in the chamber, and cooling gas is sprayed from the nozzle 9, and the steel plate is cooled. cool down. After the sheet is rapidly cooled to about 600°C at a rate of more than 27°C / S, it is quickly transferred to a hot stamping die for rapid forming, quenching, and pressure-holding for a period of time, so as to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com