Internal and external alternating type totally-closed water cooling structure applied to permanent magnet traction motor

A traction motor and alternating technology, which is applied in the field of internal and external alternating fully enclosed water-cooling structures, can solve the problems of difficult heat dissipation and limited size of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

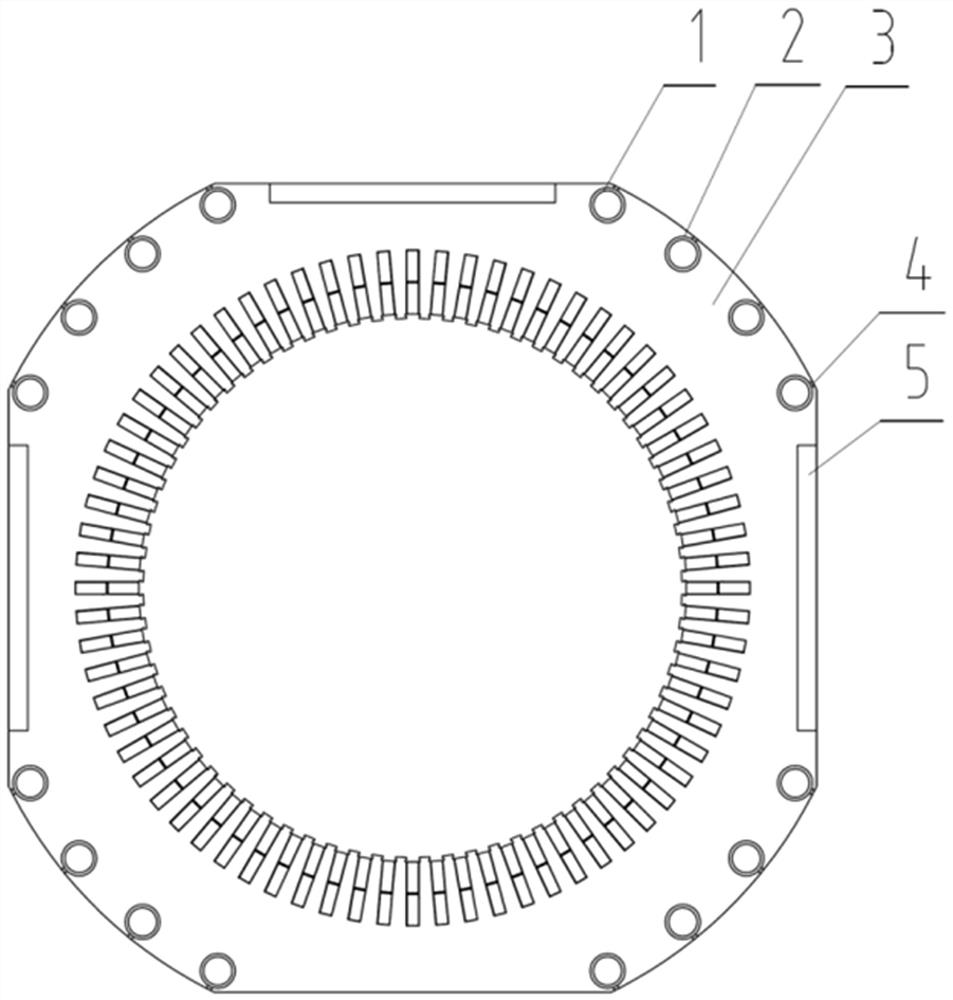

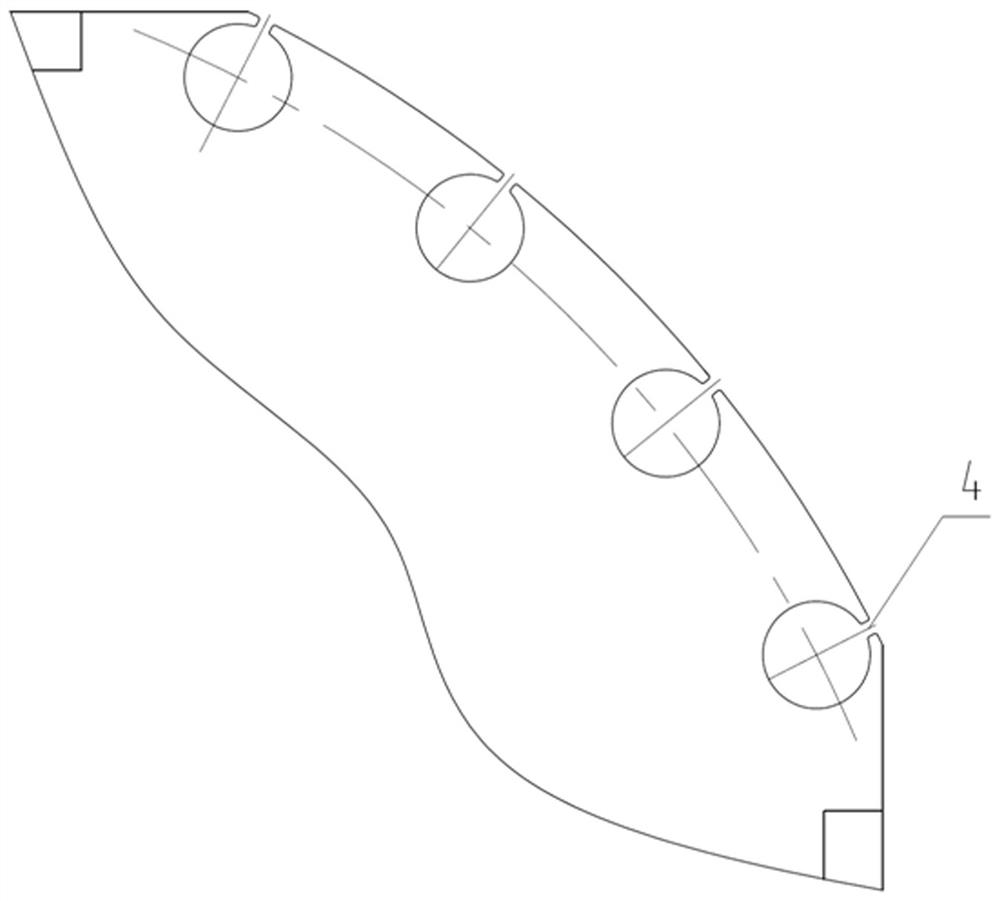

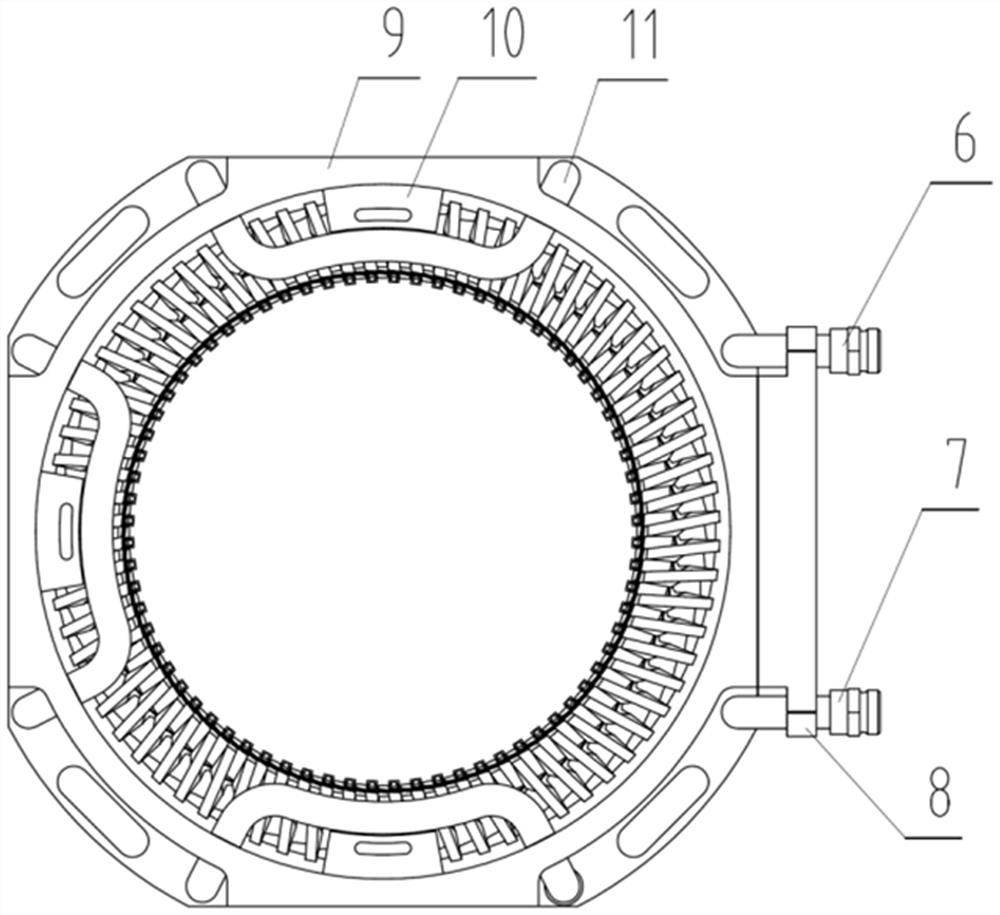

[0041] Aiming at the field of rail transit, the invention provides a water-cooled structure of a traction motor with compact structure, fully enclosed, and high torque requirements. The structure adopts a fully laminated iron core, and the cooling pipelines are arranged at the four corners of the core. The cooling pipelines cool the stator punches and the winding ends in the inner cavity of the stator at the same time. Its structural outline drawing and relevant part views are as follows: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 Shown:

[0042] 1) The present invention adopts a fully laminated welded iron core structure, and the iron core is composed of stator pressure rings at both ends, stator punching sheets and four pull plates welded (see Figure 5), making full use of the structural advantages of the frameless machine base. The stator stamping adopts octagonal stamping, and the cooling pipeline is arranged at the four corners that do not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com