Frequency conversion sub-power high-speed automobile

A variable frequency motor, high-speed technology, applied in the direction of electric vehicles, motor vehicles, power devices, etc., can solve the problems that power vehicles cannot adapt, and achieve the effects of fast speed increase, low noise and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

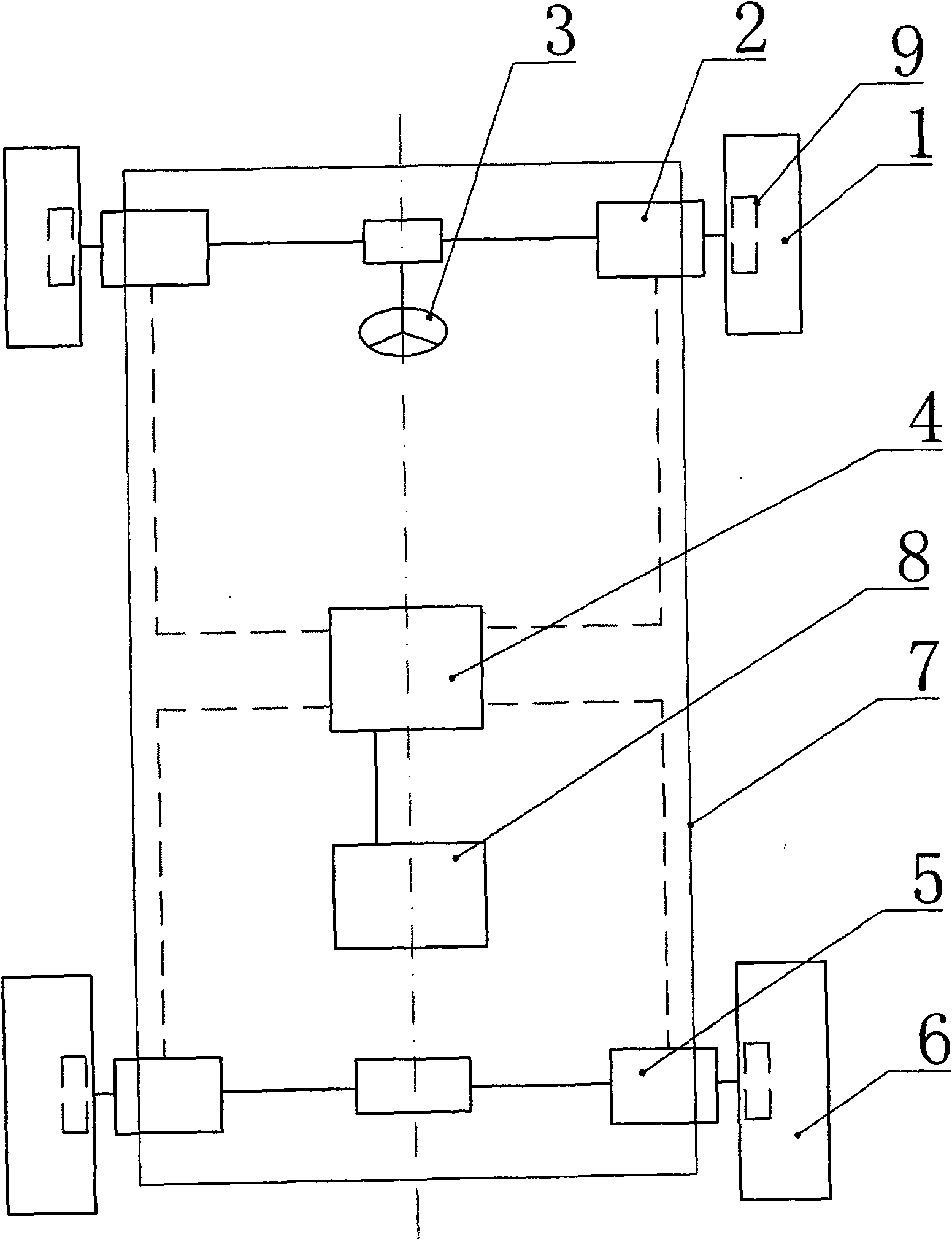

[0011] see figure 1 , the present invention comprises a chassis 7, a front wheel 1 and a rear wheel 6, two front wheels 1 and two rear wheels 6 are installed on both sides of the front end and the rear end of the chassis 7 respectively through a wheel shaft, in the middle of the two front wheels 1 There are only steering mechanism and steering wheel 3, and it is characterized in that: frequency conversion motors 2 and 5 are respectively housed on the axles of the two front wheels 1 and two rear wheels 6, and the frequency conversion motors are all connected with one figure 2 The frequency converter control system 4 shown is connected, the frequency conversion motors 2, 5 and the frequency converter control system 4 are powered by a vehicle-mounted battery 8, and are equipped with a charging controller (not shown).

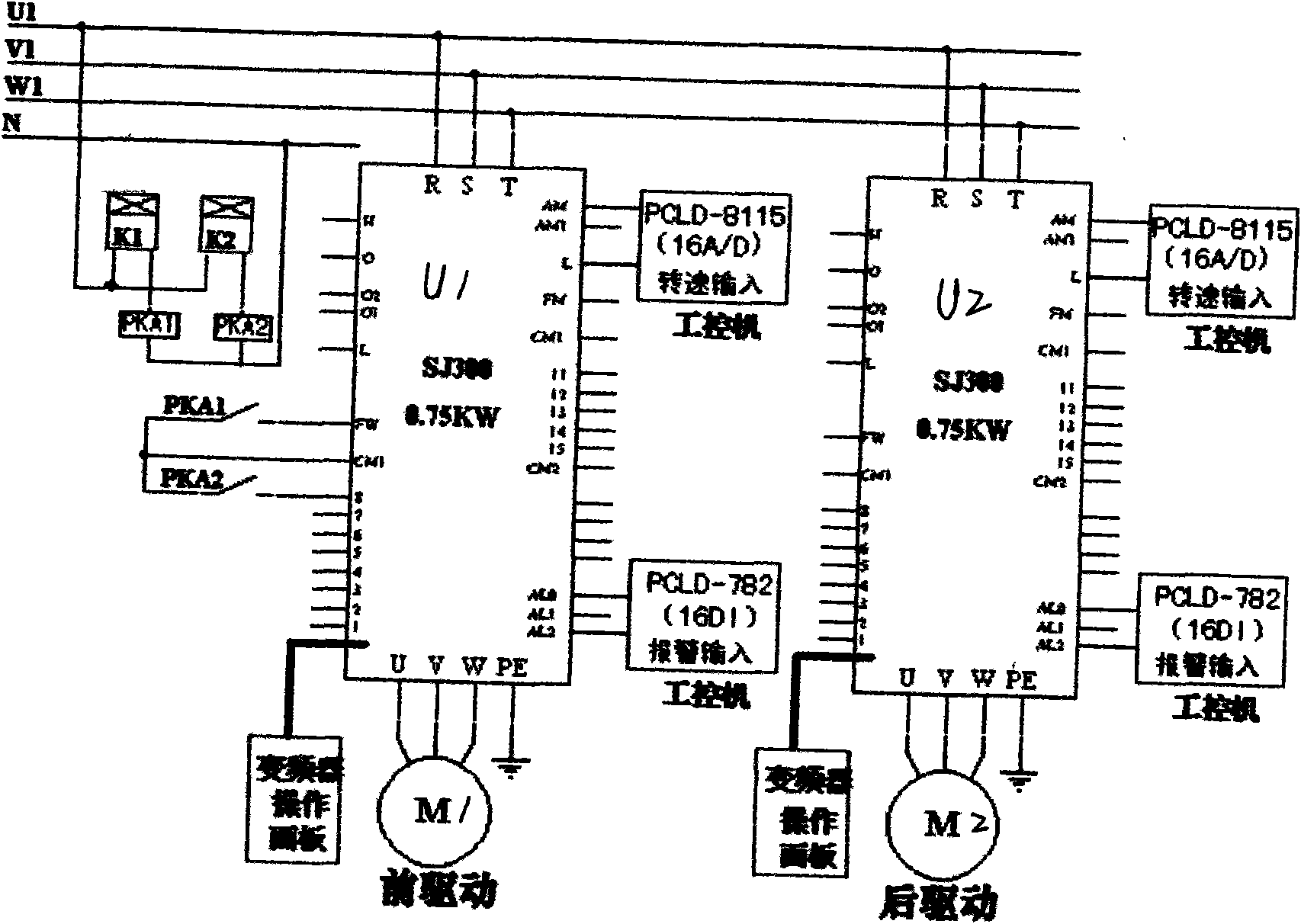

[0012] see figure 2 , is the wiring diagram between the frequency converter and the variable frequency motor. There are four frequency converters in frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com