Tribological performance evaluation testing machine of overloading impact of bearing

A technology of impact friction and bearing overload, which is used in impact testing, mechanical bearing testing, machine/structural component testing, etc. to improve experimental efficiency and reduce experimental costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

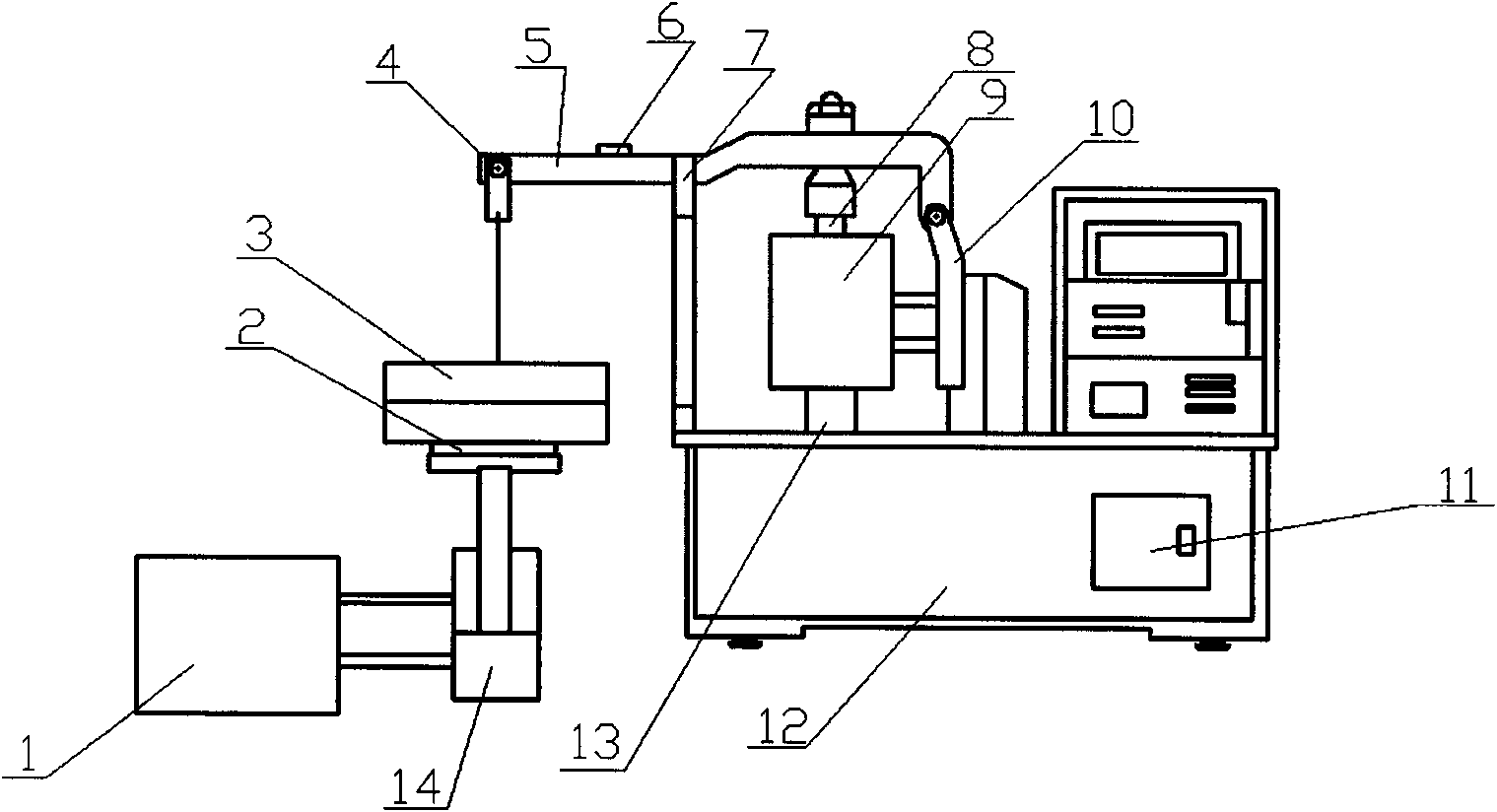

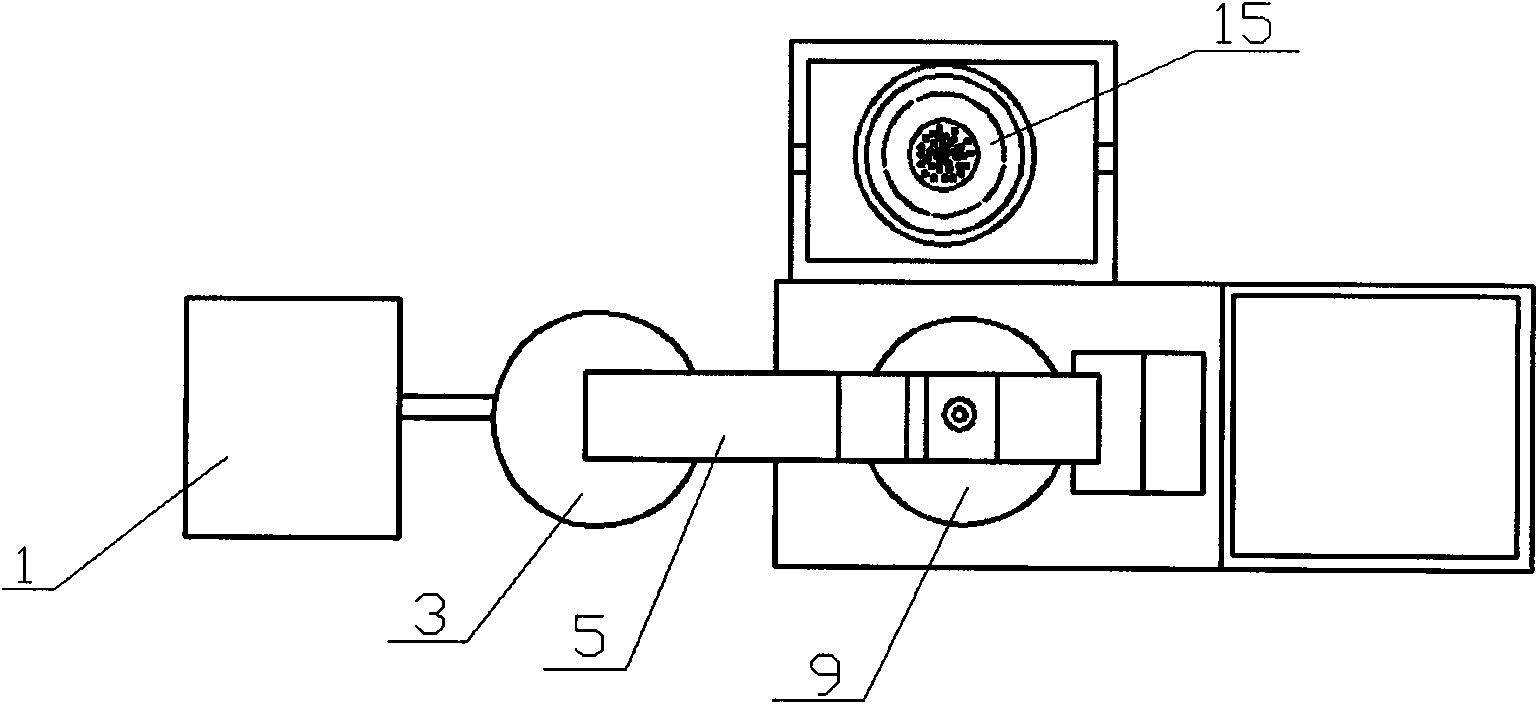

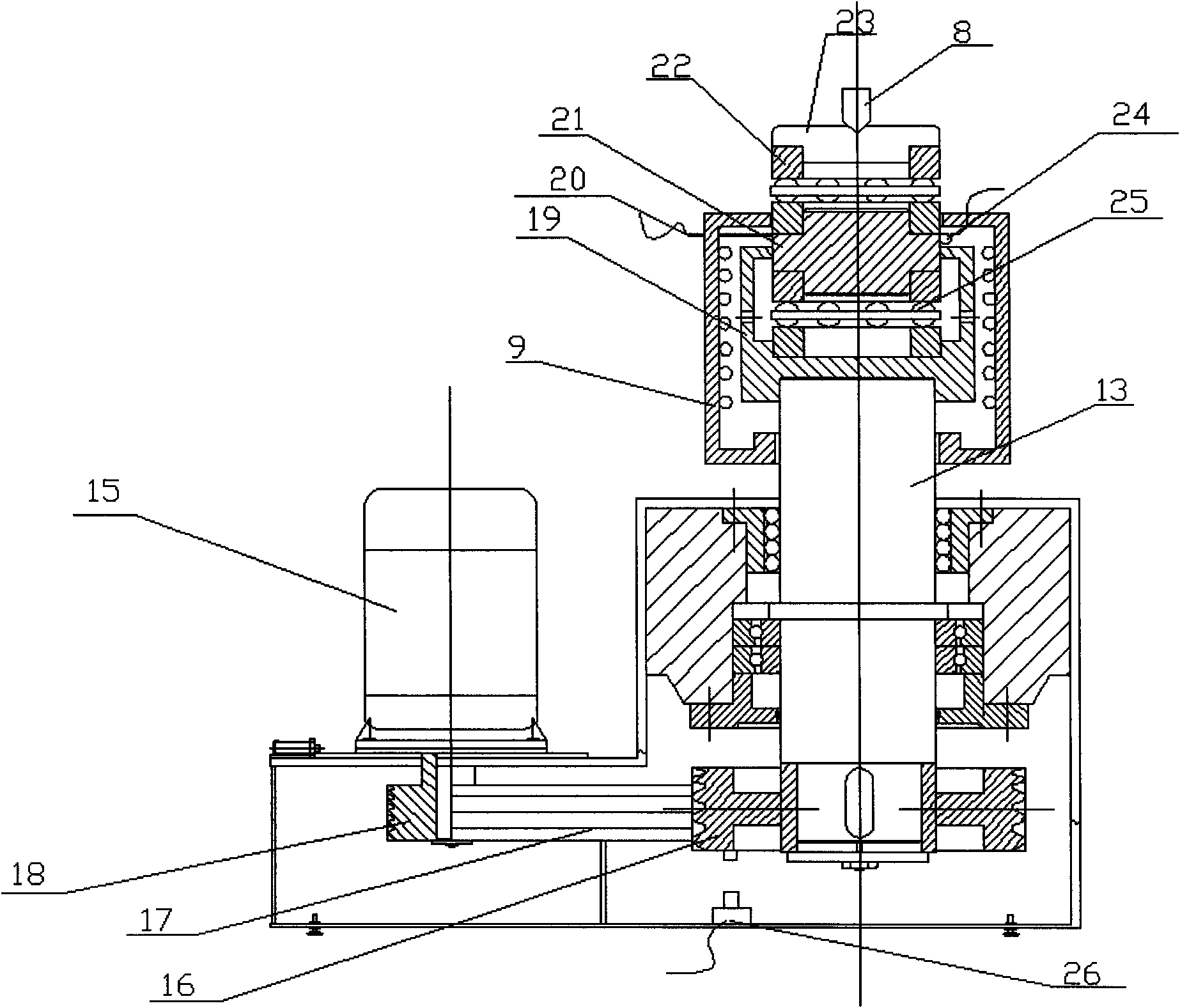

[0018] The composition of this bearing overload impact tribological performance evaluation test machine proposed by the present invention includes a transmission device, a loading device, a test chamber device and a detection device, such as figure 1 , figure 2 with image 3 shown.

[0019] Transmission device is made up of frequency conversion speed regulating motor 15, large belt pulley 16, small belt pulley 18 and power transmission shaft 13. The variable frequency speed regulating motor 15 is connected with the small pulley 18 transmission on the transmission shaft 13 through the large belt pulley 16, the belt 17, and the rotating speed of the frequency variable speed regulating motor 15 is regulated by the frequency conversion speed regulating system in the control box 11.

[0020] The loading device is composed of a pressure block 8, a loading lever 5, a weight 3, and a loading seat 2. One end of the loading lever 5 is hingedly connected with the bracket 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com