High abrasion-resistant alloy cast iron drying cylinder for papermaking machinery

A technology of alloy cast iron and papermaking machinery, which is applied in papermaking machines, papermaking, textiles and papermaking, etc., can solve the problems of high surface hardness requirements of drying cylinders, high requirements for balance precision of drying cylinders, and reduced service life of drying cylinders. Effects of saving materials and energy, reducing weight, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

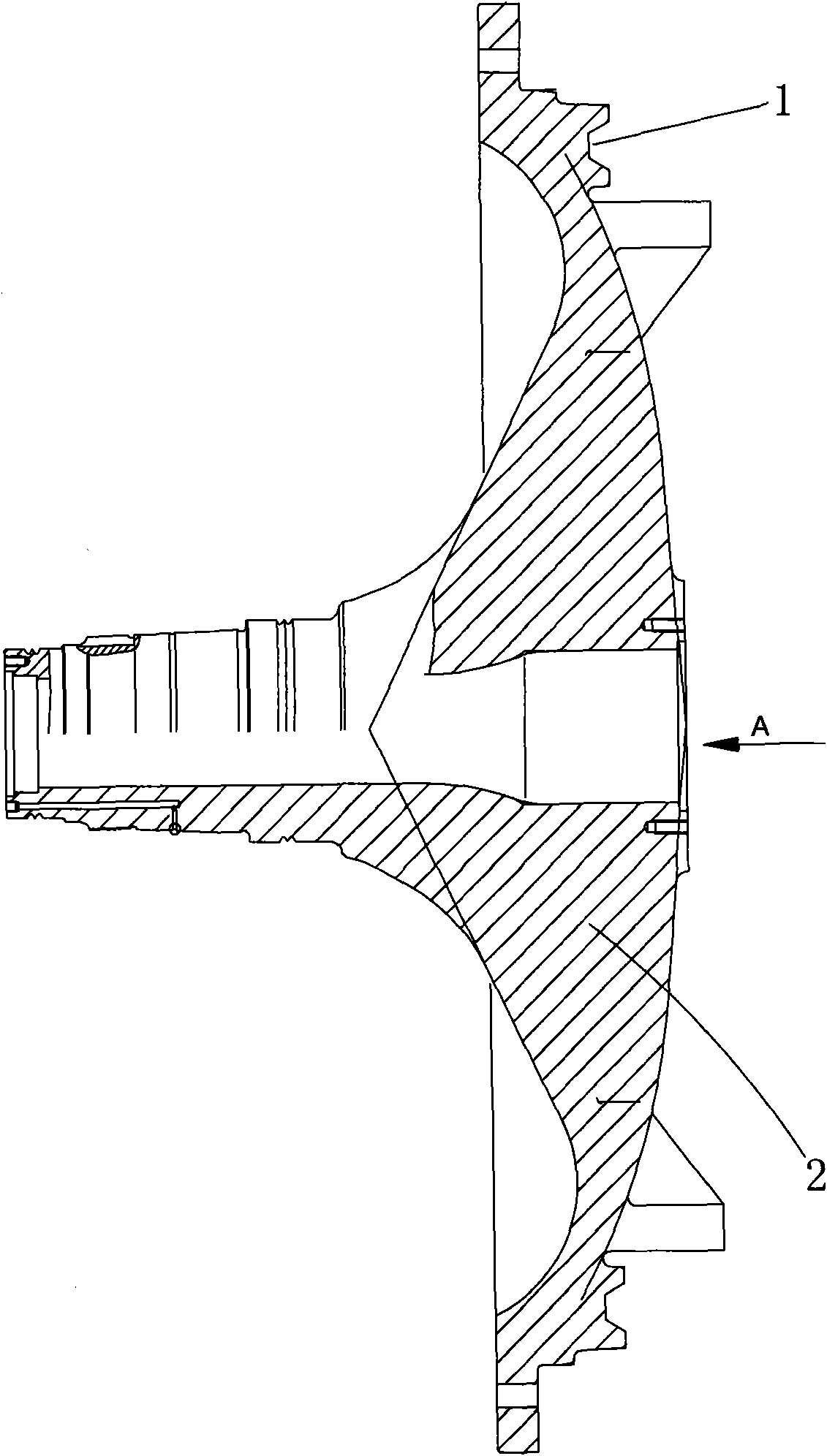

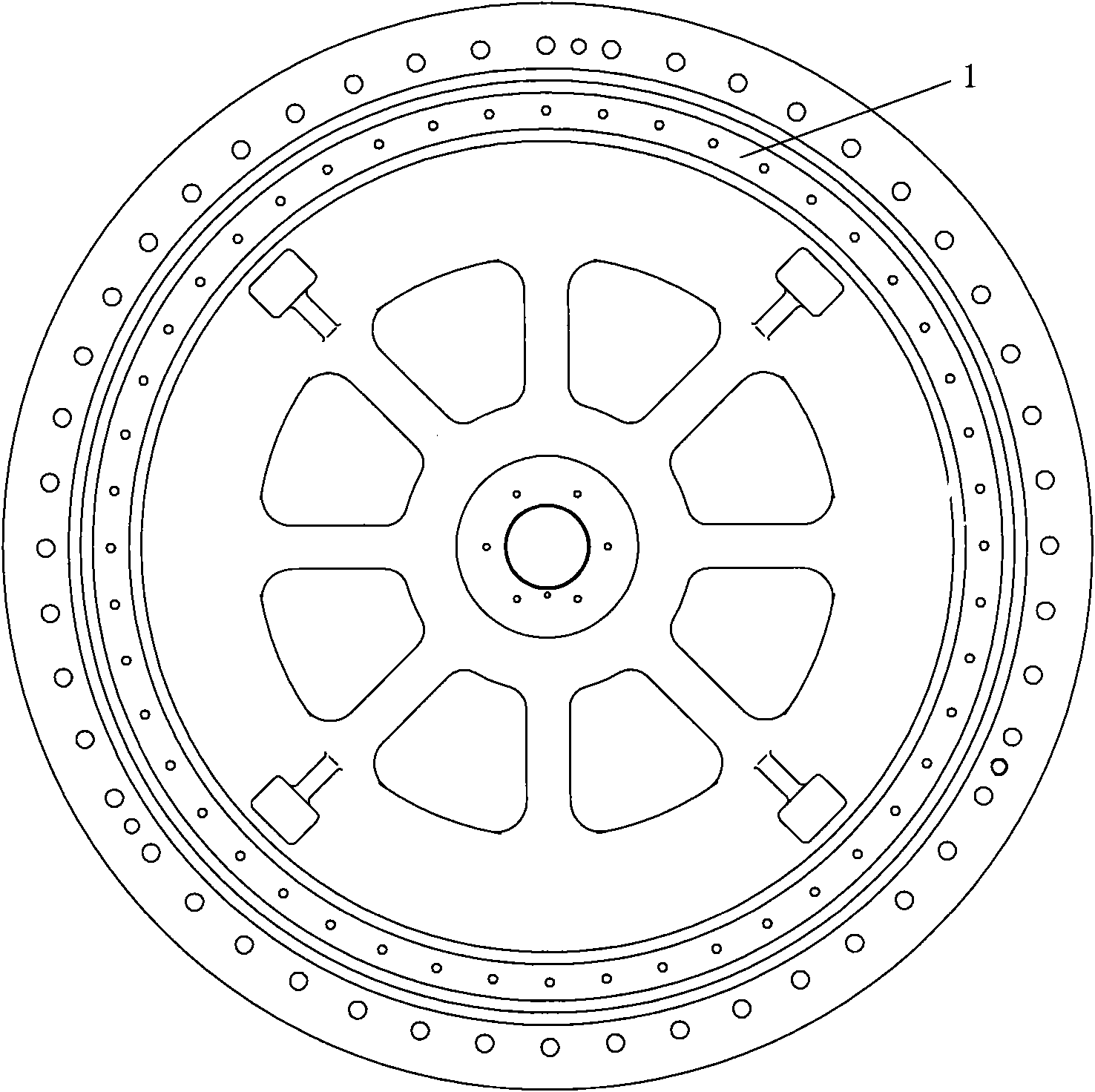

[0014] Embodiment: A high wear-resistant alloy cast iron drying cylinder for papermaking machinery, including a cylinder body and a cylinder head 2, a balance groove 1 is provided on the side of the cylinder head facing the cylinder body, and a balance weight matching the balance groove is fixed in the balance groove The position set in the center restricts the rotation direction of the balance weight and ensures the firm assembly of the balance weight.

[0015] The cylinder head is made of ductile iron QT500-7.

[0016] At least one of manganese, silicon, chromium and nickel is added to the material of the cylinder block.

[0017] The balance groove is ring-shaped and opened on the side of the cylinder head facing the cylinder block, and has a trapezoidal cross section, and a balance weight with a trapezoidal cross section is fixed in the balance groove by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com