Injection strategy of internal combustion-air mixed power device

A technology of hybrid power and injection method, which is applied to internal combustion piston engines, combustion engines, engines with one-way flow principle, etc., can solve the problems of reduced reliability of fuel supply system, failure to achieve hybrid power effect, and increased cost of internal combustion power, etc. Achieve the effect of low emission, low noise and low vibration, solve the difficulty of ignition phase control, and solve the difficulty of cold start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

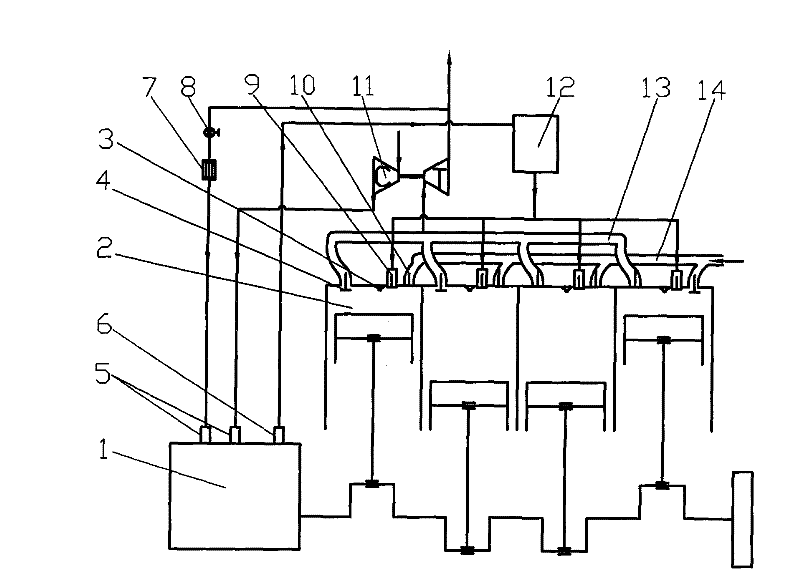

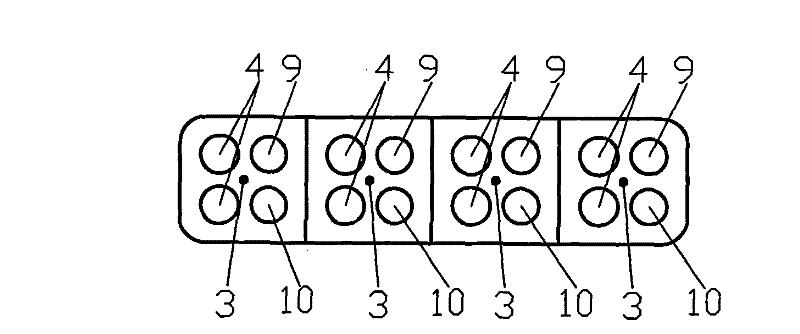

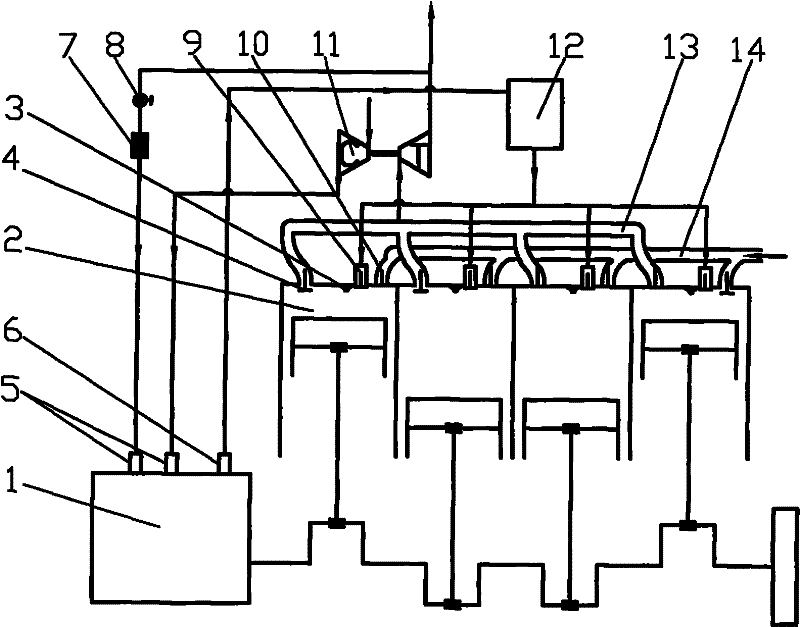

[0018] figure 1 , 2 A schematic diagram of an internal combustion-aerodynamic hybrid device is shown. In the figure, the intake system, exhaust system, fuel system and their control devices of the internal combustion power are not shown in detail. The internal combustion-air hybrid power device mainly includes a compressor 1 , an internal combustion power 2 and a high-pressure air tank 12 . The exhaust gas turbocharger 11 of the exhaust system allows the first-stage pressurized air and the exhaust gas introduced through the EGR valve 8 to enter the compressor 1 through the compressor inlet valve 5, and is compressed by the second stage in the compressor 1 to become high pressure. After the air enters the high-pressure air tank 12 through the high-pressure air tank charging valve 6; the internal combustion power intake system is a natural suction or turbocharged air intake manifold 14 and a pipe that is charged to the internal combustion power 2 by the high-pressure air tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com