Fixedly coupled three-shaft servo seepage pressure chamber containing gas coal thermal flow

A three-axis servo, seepage pressure technology, used in permeability/surface area analysis, suspension and porous material analysis, measurement devices, etc., can solve the problems of inaccurate coal and rock deformation data, single influencing factor of permeability, gas leakage, etc. , to achieve the effect of improving the survival rate and data acquisition stability, high sensitivity and accuracy, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

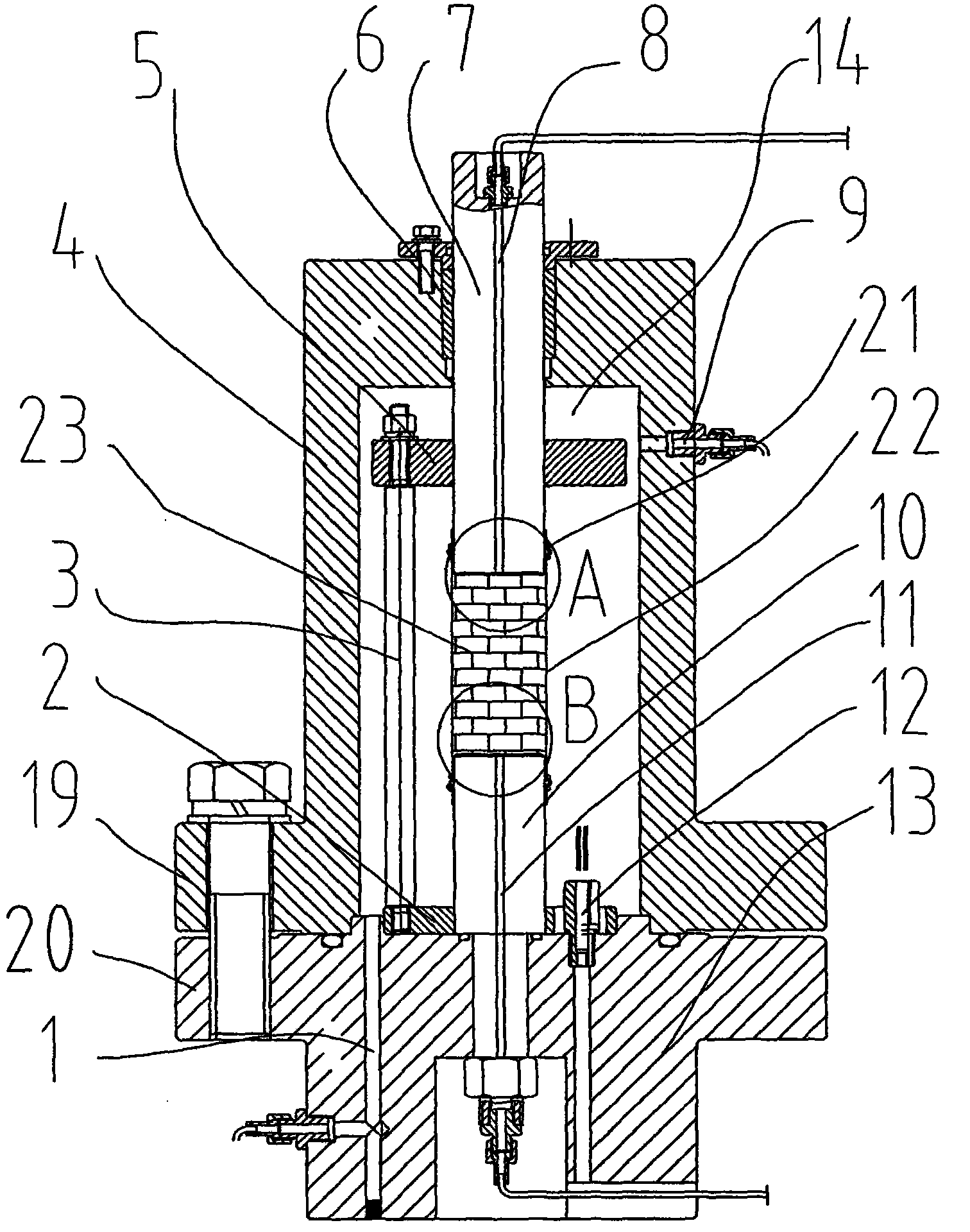

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

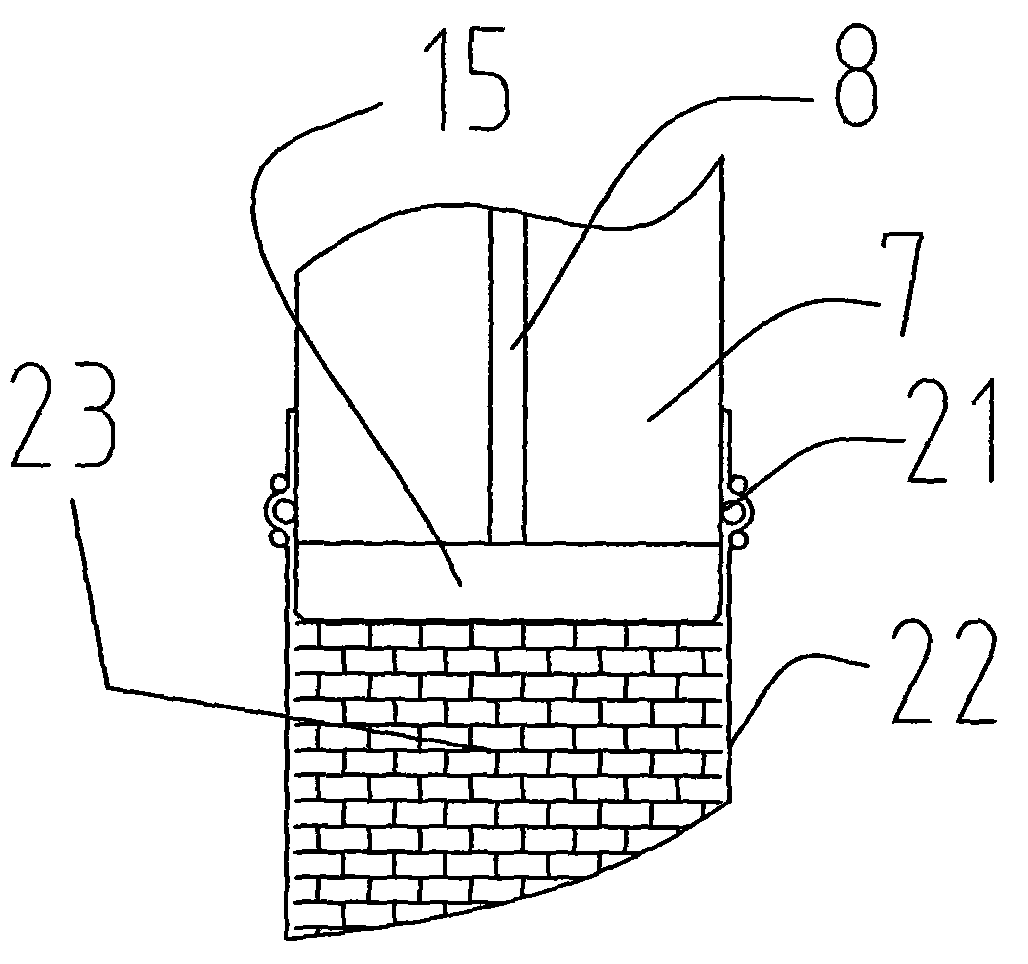

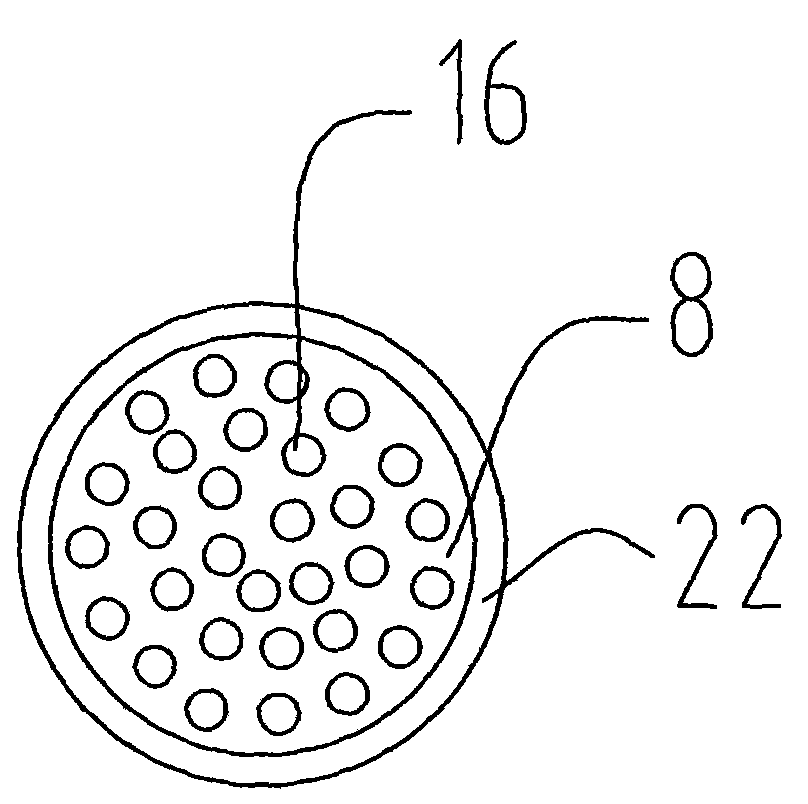

[0042] See Figure 1 to Figure 5 : The shown gas-containing coal heat-fluid-solid coupling three-axis servo seepage pressure chamber is composed of an upper seat 4, a lower seat 13, a test chamber 14, a pressurized piston rod 7, a support shaft 10, a guide device and a sensor terminal 12. The upper seat 4 is provided with a test chamber 14 with an opening downward. The upper seat 4 above the test chamber 14 has a through hole in the axial direction, and the lower seat 13 has a stepped through hole in the axial direction. The upper seat 4 is installed on the lower seat 13. Above, the lower seat 13 and the upper seat 4 are respectively provided with an emptying hole 9 and an oil inlet and outlet 1 communicating with the test chamber 14, so that the oil can enter the test chamber 14, and it is convenient to drain the oil when the test is completed. Before discharge and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com