Shielding contact box of high-voltage switch cabinet

A technology of high-voltage switchgear and contact box, applied in the field of contact box, to achieve the effect of reducing partial discharge, eliminating corona phenomenon, and superior electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

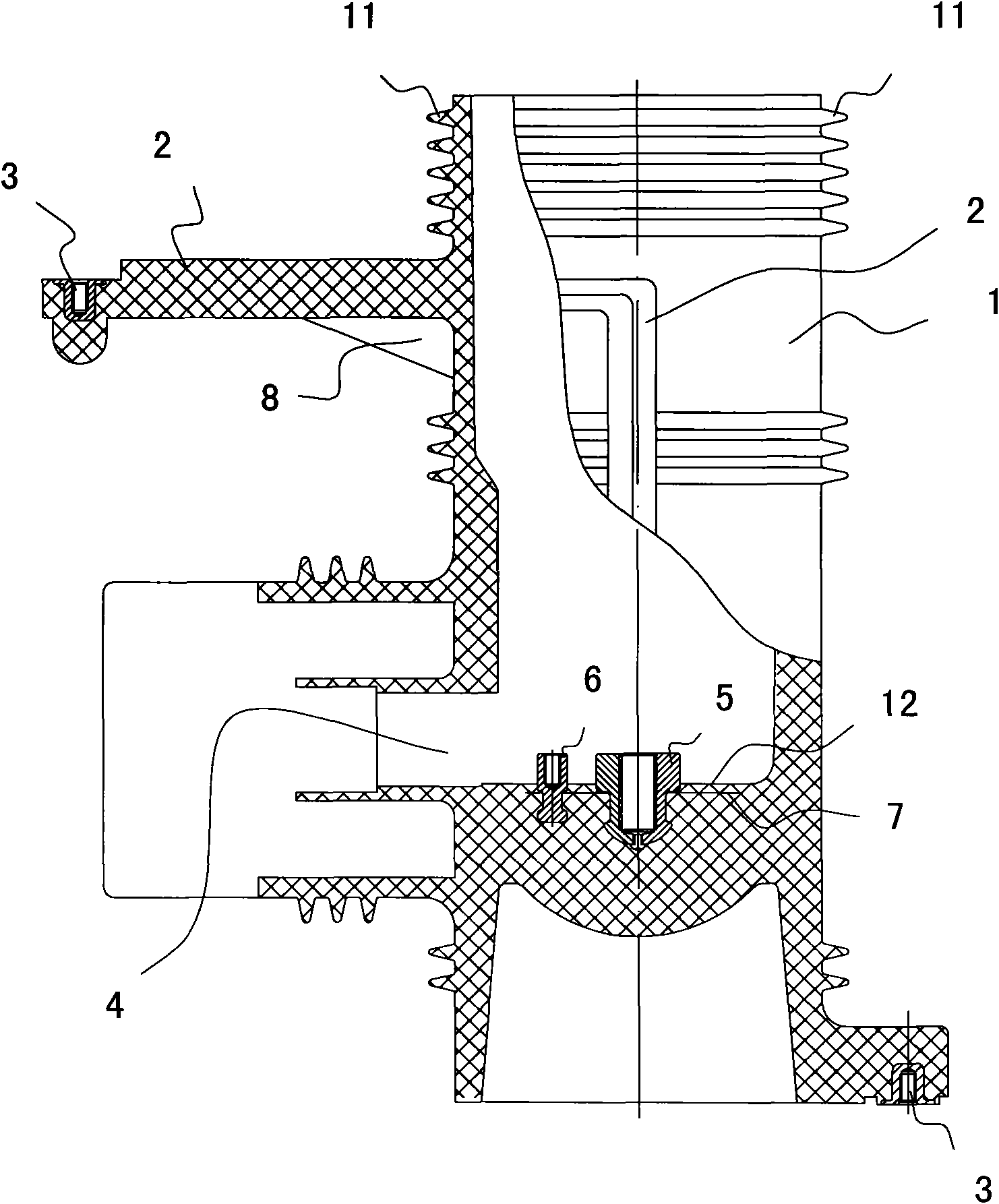

[0012] see figure 1 . The box body 1 and the support plate 2 are integrally formed by epoxy pressure gel at one time, and the outer walls of both are provided with umbrella skirts 11 , and the outer edges of the adjacent contact box support plates 2 form overlapping surfaces. The box body 1 is cylindrical, with an open upper end and a lower end closed by the bottom wall 12 of the inner cavity of the box. Corresponding to the bottom wall 12 of the inner cavity of the box body, a radial female discharge port 4 is provided on the wall of the box body 1 for receiving the busbar. On the bottom wall 12 of the inner cavity of the box, a static contact mounting insert 5 and a busbar fixing insert 6 are arranged respectively, and the axes of the screw holes of the two are on a straight line, so as to fix the busbar in a straight line. The non-magnetic metal shielding layer 7, that is, the wire mesh layer or the metal sheet layer, together with the static contact mounting insert 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com