Application of high-strength high-mode polyethylene fiber to flexible optical cable manufacturing

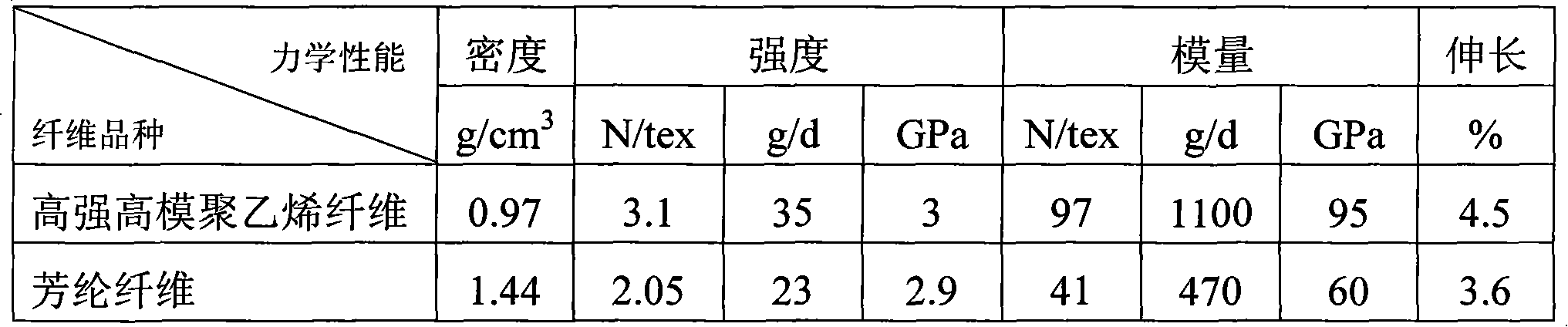

A polyethylene fiber, high-strength and high-modulus technology, applied in the direction of fiber mechanical structure, can solve problems such as insufficient density, strength, modulus and elongation, obstacles to the popularization and use of soft optical cables, and high price of aramid fibers, etc., to achieve reduction Quality, improved strength and modulus, excellent UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

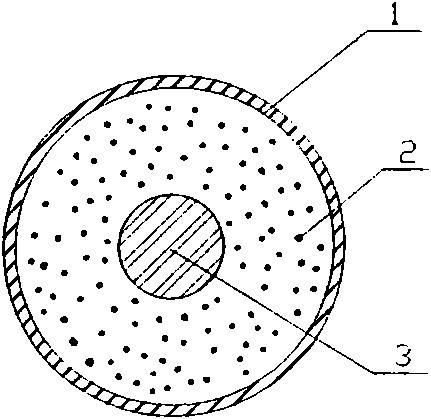

[0022] The high-strength high-modulus polyethylene fiber is applied to the manufacture of flexible optical cables. The manufacturing method includes the following steps: (1) optical fiber pay-off and high-strength high-modulus polyethylene fiber pay-off: the optical fiber is released from the optical fiber reel by the optical fiber pay-off device, and the optical fiber pay-off The tension is 0.5N±0.2N, and the specification of optical fiber reel is 400mm; at the same time, the high-strength and high-modulus polyethylene fiber is released from the high-strength and high-modulus polyethylene fiber bobbin by the high-strength and high-modulus polyethylene fiber pay-off device and coated on the outside of the optical fiber. The tension of the high-strength and high-modulus polyethylene fiber is 0.5N±0.05N. The size of the bobbin is 94× 290×290mm;

[0023] (2) The sheath material is extruded by an extruder and coated on the outside of the high-strength high-modulus polyethylen...

Embodiment 2

[0027] The high-strength high-modulus polyethylene fiber is applied to the manufacture of flexible optical cables. The manufacturing method includes the following steps: (1) optical fiber pay-off and high-strength high-modulus polyethylene fiber pay-off: the optical fiber is released from the optical fiber reel by the optical fiber pay-off device, and the optical fiber pay-off The tension is 2N±0.2N, and the specification of the optical fiber reel is 400mm; at the same time, the high-strength and high-modulus polyethylene fiber is released from the high-strength and high-modulus polyethylene fiber bobbin by the high-strength and high-modulus polyethylene fiber pay-off device and coated on the outside of the optical fiber. The tension of the high-strength and high-modulus polyethylene fiber pay-off is 5N±0.05N. The cylinder size is 94× 290×290mm;

[0028] (2) The sheath material is extruded by an extruder and coated on the outside of the high-strength high-modulus polyethy...

Embodiment 3

[0032] The high-strength high-modulus polyethylene fiber is applied to the manufacture of flexible optical cables. The manufacturing method includes the following steps: (1) optical fiber pay-off and high-strength high-modulus polyethylene fiber pay-off: the optical fiber is released from the optical fiber reel by the optical fiber pay-off device, and the optical fiber pay-off The tension is 4N±0.2N, and the specification of optical fiber reel is 400mm; at the same time, the high-strength high-modulus polyethylene fiber is released from the high-strength high-modulus polyethylene fiber yarn tube by the high-strength high-modulus polyethylene fiber pay-off device and wrapped on the outside of the optical fiber. The tension of the high-strength high-modulus polyethylene fiber pay-off is 10N±0.05N. The cylinder size is 94× 290×290mm;

[0033] (2) The sheath material is extruded by an extruder and coated on the outside of the high-strength high-modulus polyethylene fiber to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tension | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com