36-pulse high-power frequency conversion rectifier transformer

A rectifier transformer, high-power technology, applied in the direction of transformers, fixed transformers, transformer/inductor coils/windings/connections, etc., can solve the problems of grid pollution, increased noise, malfunction, etc., and achieves less on-site wiring and improved The effect of reliability and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

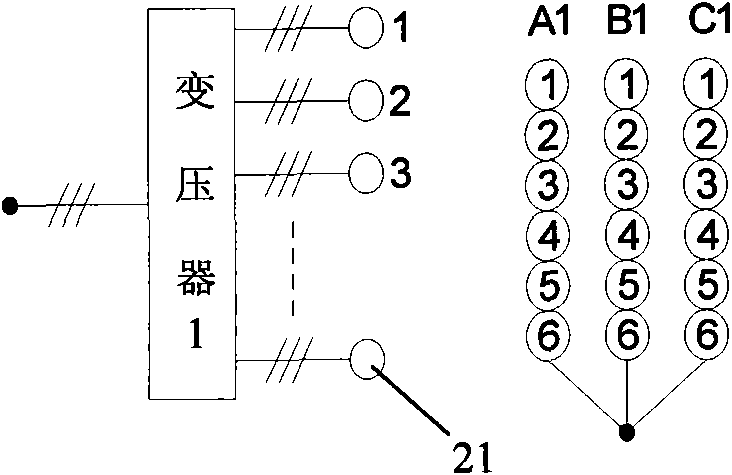

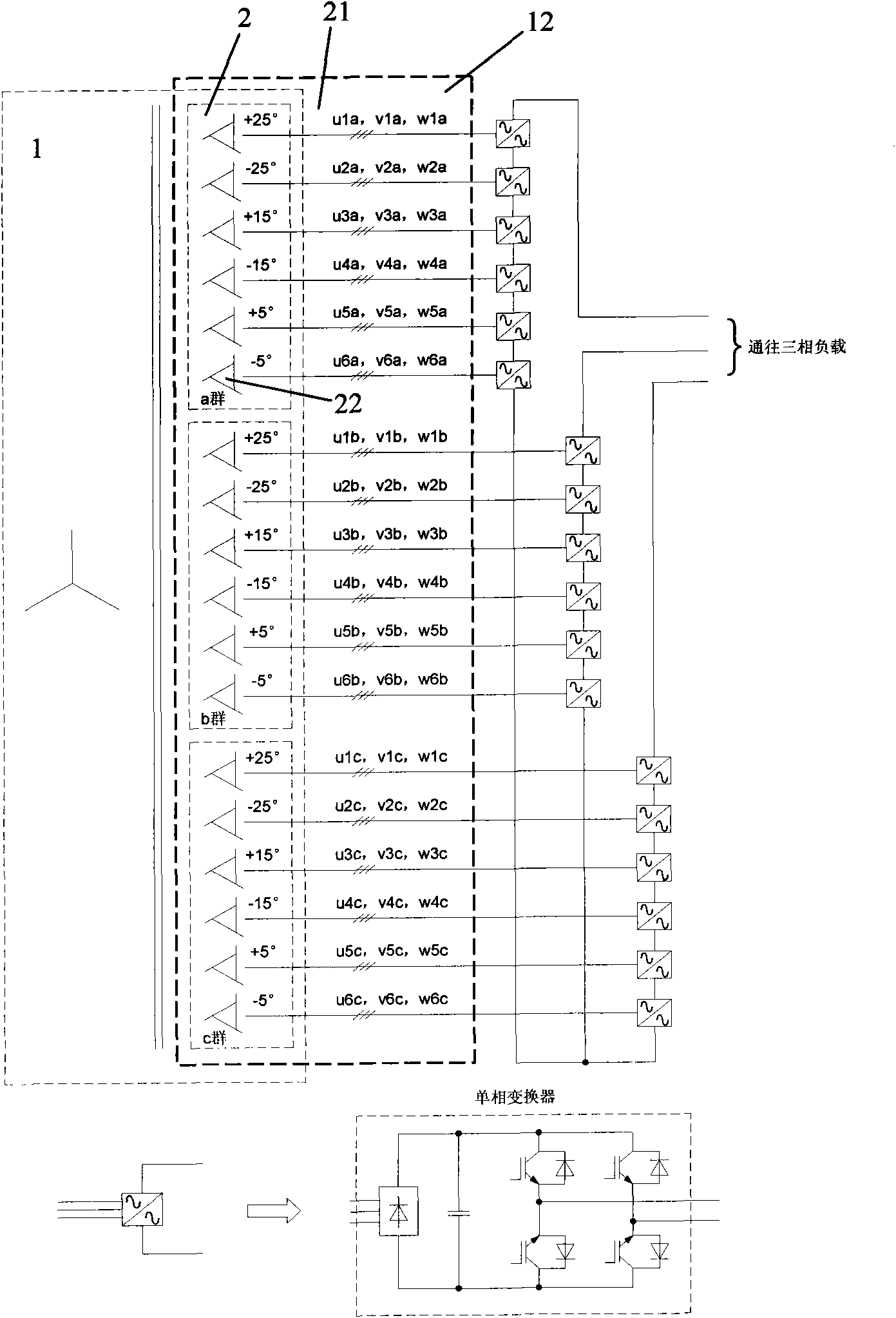

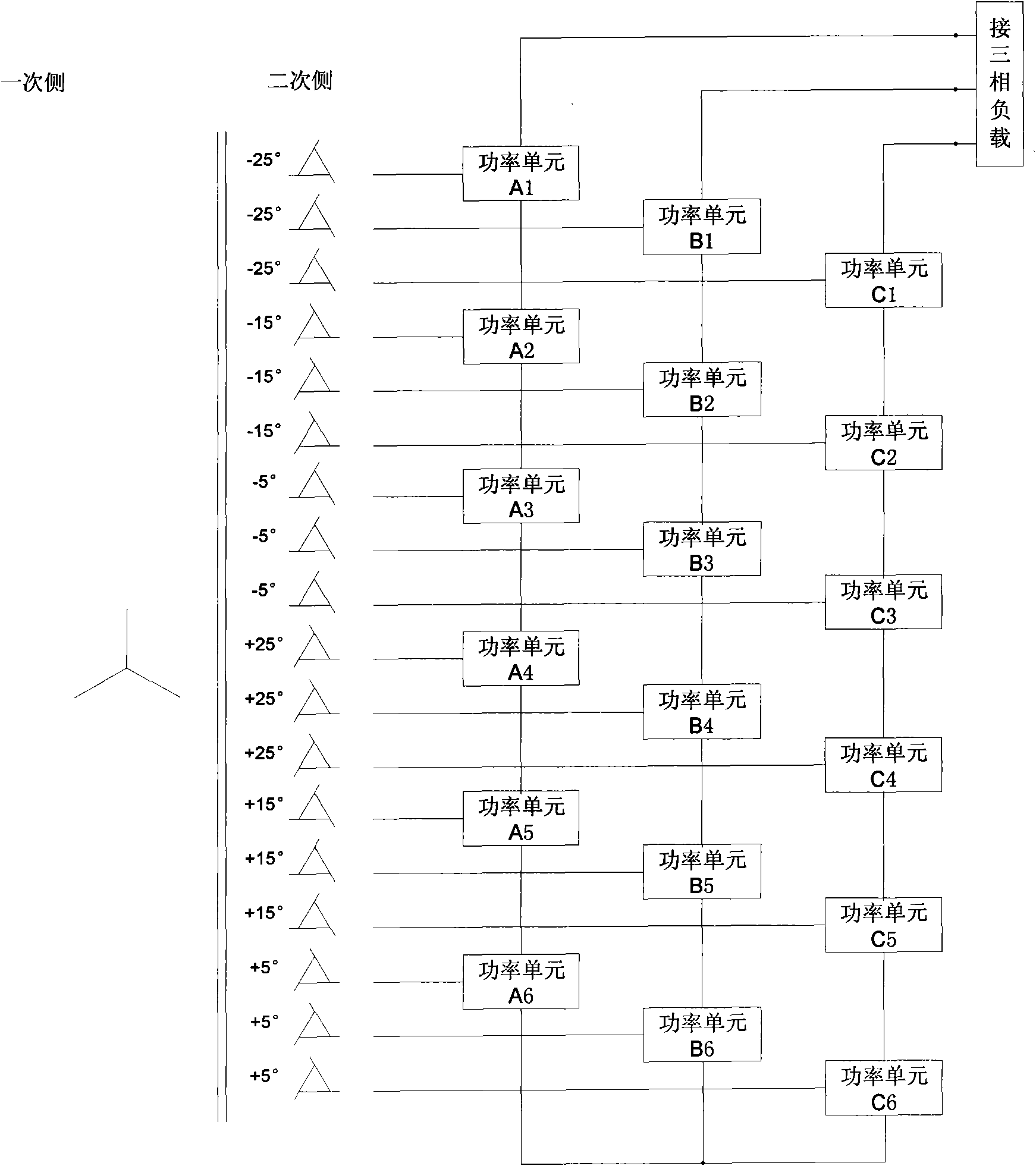

[0017] For multiple, high-voltage, frequency converters with AC-DC-AC units in series with multi-level voltage source frequency converters, the schematic block diagram of the 36-pulse rectifier transformer is as follows: figure 1 shown. In order to obtain the required high voltage of a certain value, the output of each phase of the transformer 1 needs to be formed by a plurality of power units 21 connected in series. , A total of 18 power units in three phases as an example, each power unit bears all the motor current, 1 / 6 of the phase voltage, and 1 / 18 of the output power. The 18 power units share three-phase input windings on the transformer 1 . The power units and the transformer secondary winding 11 are insulated from each other.

[0018] Such as figure 2 As shown, the transformer 1 of the present invention adopts the star Y connection method on the primary side, which is a three-phase input winding; the secondary side adopts the multiple extension delta connection met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com