Resistance heat tension straightening device and straightening method thereof

A resistance heating and straightening technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high production cost, decreased straightness, low efficiency, etc., and achieve less surface, less residual stress, and straightening accuracy stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is a straightening device for titanium alloy rods, and the material to be straightened is TC4 titanium alloy. The length of the straightening sample is 3m, and the diameter is Φ10mm. Before straightening, it is processed by hot rolling and rough grinding.

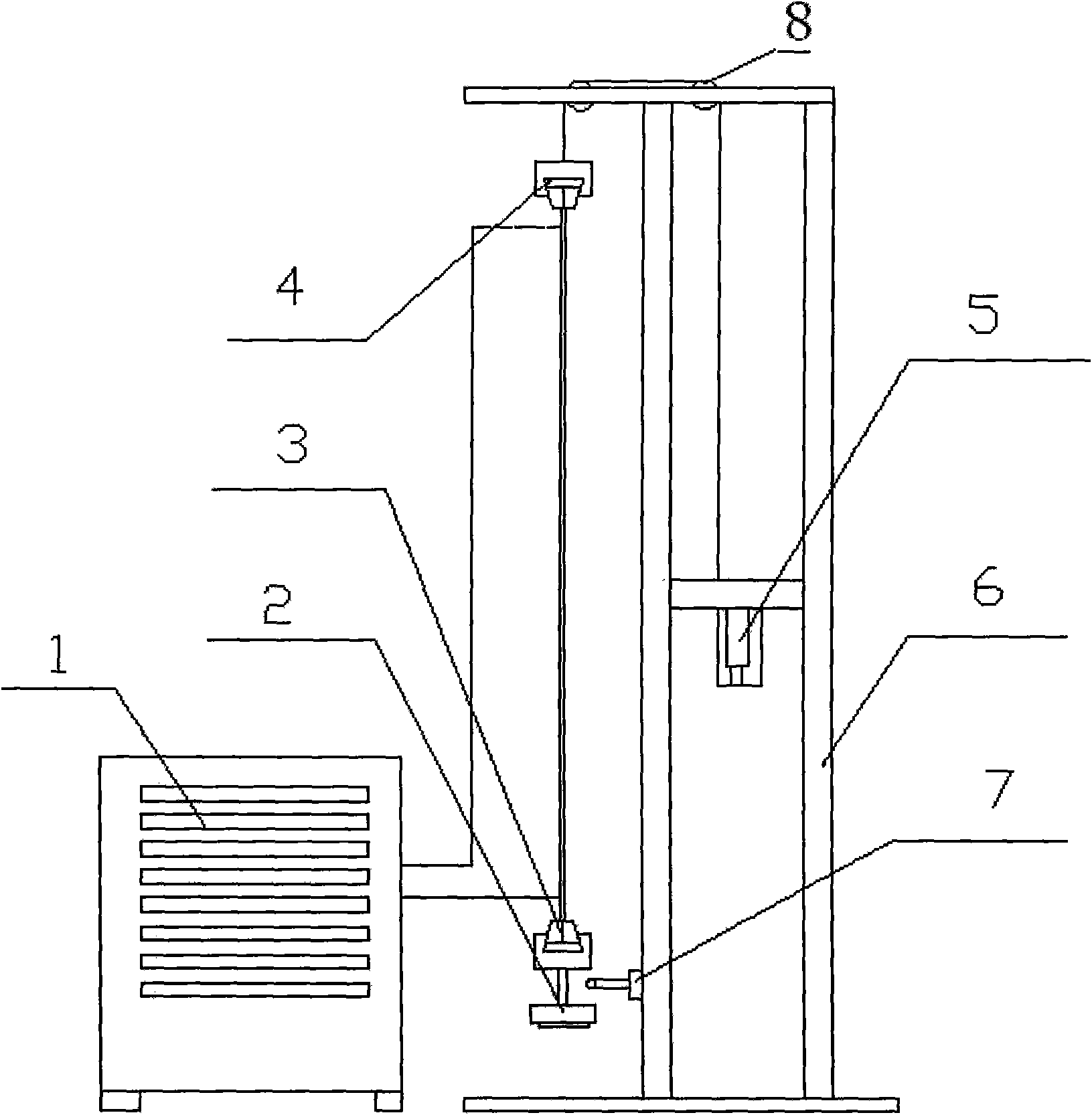

[0027] This embodiment includes a power source 1, a counterweight weight 2, a lower chuck 3, an upper chuck 4, a cylinder 5, a bracket 6, a limit switch 7 and a fixed pulley 8. Wherein, lower chuck 3 and upper chuck 4 all adopt the three-jaw chuck that lathe is used; All are equipped with connecting ring at the outer surface center of the bottom of lower chuck 3 and upper chuck 4. The power supply 1 adopts a low-voltage power adjustable power supply with a maximum power of 25KW; the cylinder 5 and the limit switch 7 are finished parts.

[0028] The support 6 is a rod structure, which is welded by angle steel and fixed on the ground; there is a fixed beam in the middle of the support 6 . A fixed pull...

Embodiment 2

[0043] This embodiment is a device for thermal straightening of molybdenum rods, and the straightened material is Mo1 pure molybdenum rods. The length of the straightened sample is 3m, the diameter is Φ6mm, and it is a hot drawn product before straightening.

[0044] This embodiment includes a power source 1, a counterweight weight 2, a lower chuck 3, an upper chuck 4, a cylinder 5, a bracket 6, a limit switch 7 and a fixed pulley 8. Wherein, lower chuck 3 and upper chuck 4 all adopt the three-jaw chuck that lathe is used; All are equipped with connecting ring at the outer surface center of the bottom of lower chuck 3 and upper chuck 4. The power supply 1 adopts a low-voltage power adjustable power supply with a maximum power of 25KW; the cylinder 5 and the limit switch 7 are finished parts.

[0045] The support 6 is a rod structure, which is welded by angle steel and fixed on the ground; there is a fixed beam in the middle of the support 6 . A fixed pulley 8 is installed at t...

Embodiment 3

[0060] This embodiment is used for a thermal straightening device for stainless steel rods, the material is 1Cr18Ni9, the length is 2.5m, and the diameter is Φ20mm. The processing state of the material is that the skin is peeled off by a centerless car after rolling, the surface is bright, and the diameter is 1%. In order to further finish grinding and obtain the bar with precision grade h7, it is necessary to straighten the bar so that its straightness is controlled within 1‰.

[0061] This embodiment includes a power source 1, a counterweight weight 2, a lower chuck 3, an upper chuck 4, a cylinder 5, a bracket 6, a limit switch 7 and a fixed pulley 8. Wherein, lower chuck 3 and upper chuck 4 all adopt the three-jaw chuck that lathe is used; All are equipped with connecting ring at the outer surface center of the bottom of lower chuck 3 and upper chuck 4. The power supply 1 adopts a low-voltage power adjustable power supply with a maximum power of 25KW; the cylinder 5 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com