Bidirectional steel and oxygen supplying method of converter steelmaking

A converter steelmaking and oxygen supply technology, applied in the manufacture of converters, etc., can solve problems such as oxygen lance shutdown accidents, mixed lance accidents, and increase the difficulty of oxygen lance management, so as to avoid production stop accidents and mixed lance accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

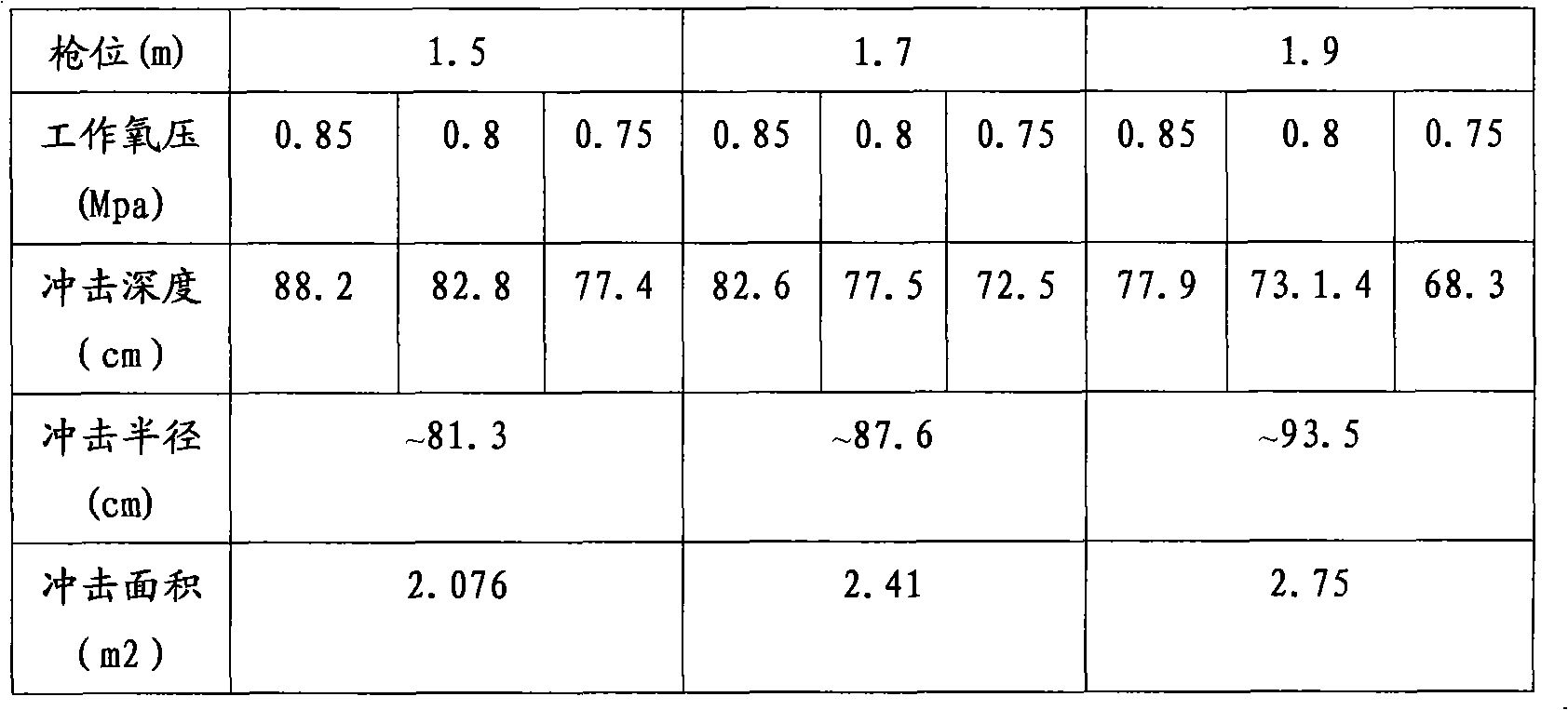

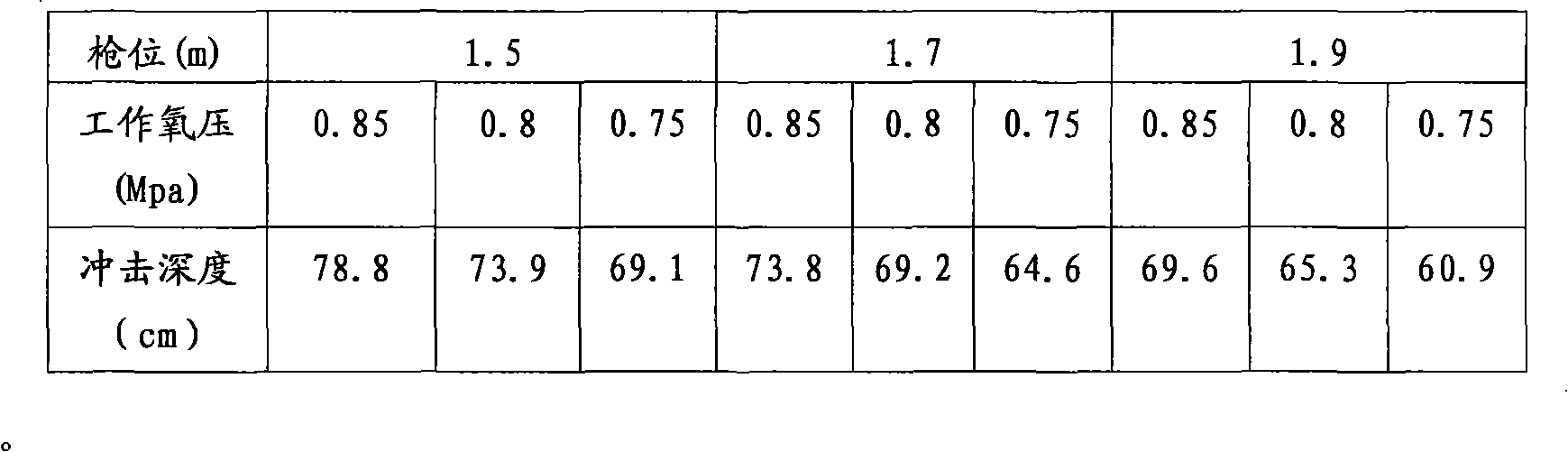

[0030] 1) Oxygen lance design was carried out for a nominal 150-ton converter in a steel plant when the loading capacity was 150 tons and 120 tons respectively, and two oxygen lance nozzles were obtained (120 tons, 5 holes (houkou 35mm) 13° oxygen gun, 150 tons of 5 holes (roar mouth 39mm) 13° oxygen lance), 30De-45De lance positions are 1050-1575mm, 1170-1755mm respectively, the oxygen lance design parameters are shown in Table 1-Table 4.

[0031] 2) Calculate the liquid level difference in the converter molten pool of 120 tons and 150 tons to be 250mm.

[0032] 3) Choose to use 120 tons of 5 holes (hou mouth 35mm) 13° oxygen lance, when the loading capacity is 120 tons, the actual execution parameters of the oxygen lance operation are: using oxygen pressure: 0.8Mpa; oxygen flow rate: 21080Nm3 / h, the basic position of the oxygen lance operation is: 1500mm;

[0033] 4) The actual execution parameters of the oxygen lance operation when the loading capacity is 150 tons are: ...

Embodiment 2

[0037] 1) Oxygen lance design was carried out for a nominal 150-ton converter in a steel plant when the loading capacity was 150 tons and 120 tons respectively, and two oxygen lance nozzles were obtained (120 tons, 5 holes (houkou 34.5mm) 15° oxygen lance, 150 tons of 5 holes (roar mouth 39mm) 15 ° oxygen gun), 30De-45De gun positions are 1035-1552mm, 1170-1755mm respectively.

[0038] 2) Calculate the liquid level difference in the converter molten pool of 120 tons and 150 tons to be 250mm.

[0039] 3) Choose to use 120 tons of 5 holes (hou mouth 34.5mm) 15° oxygen lance, when the loading capacity is 120 tons, the actual execution parameters of the oxygen lance operation are: oxygen pressure: 0.81Mpa; oxygen flow rate: 21000Nm3 / h, the basic position of the oxygen lance operation is: 1400mm;

[0040] 4) The actual execution parameters of the oxygen lance operation when the loading capacity is 150 tons are:

[0041] A. Oxygen flow rate: 24000Nm3 / h. Oxygen pressure: 0.86M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com