High-potential sacrificial magnesium alloy anode and manufacturing method thereof

A sacrificial anode and magnesium alloy technology, applied in the field of low-cost high-potential magnesium alloy sacrificial anode, can solve the problems of easy moisture absorption, high content, lower sacrificial anode potential and current efficiency, etc., and achieve simple manufacturing process and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

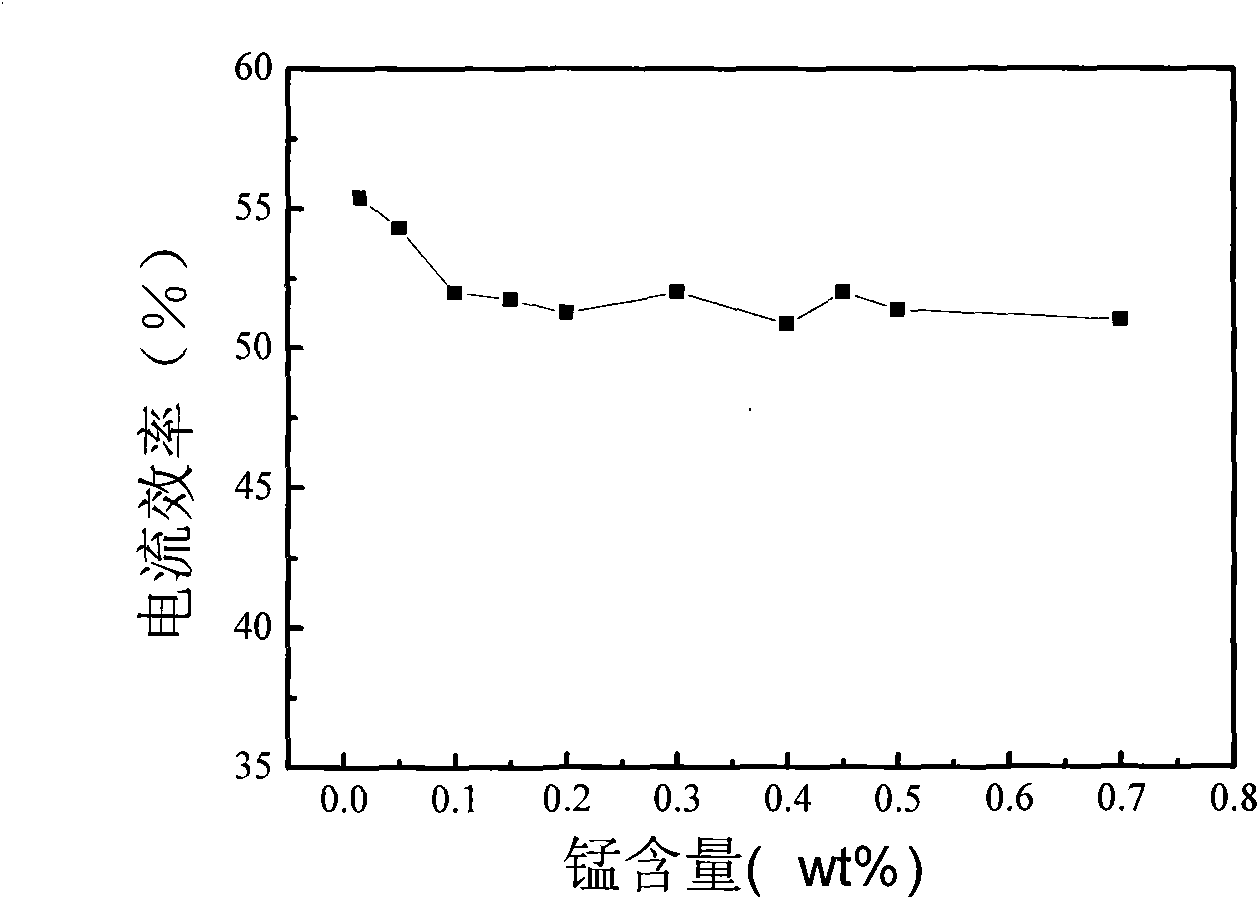

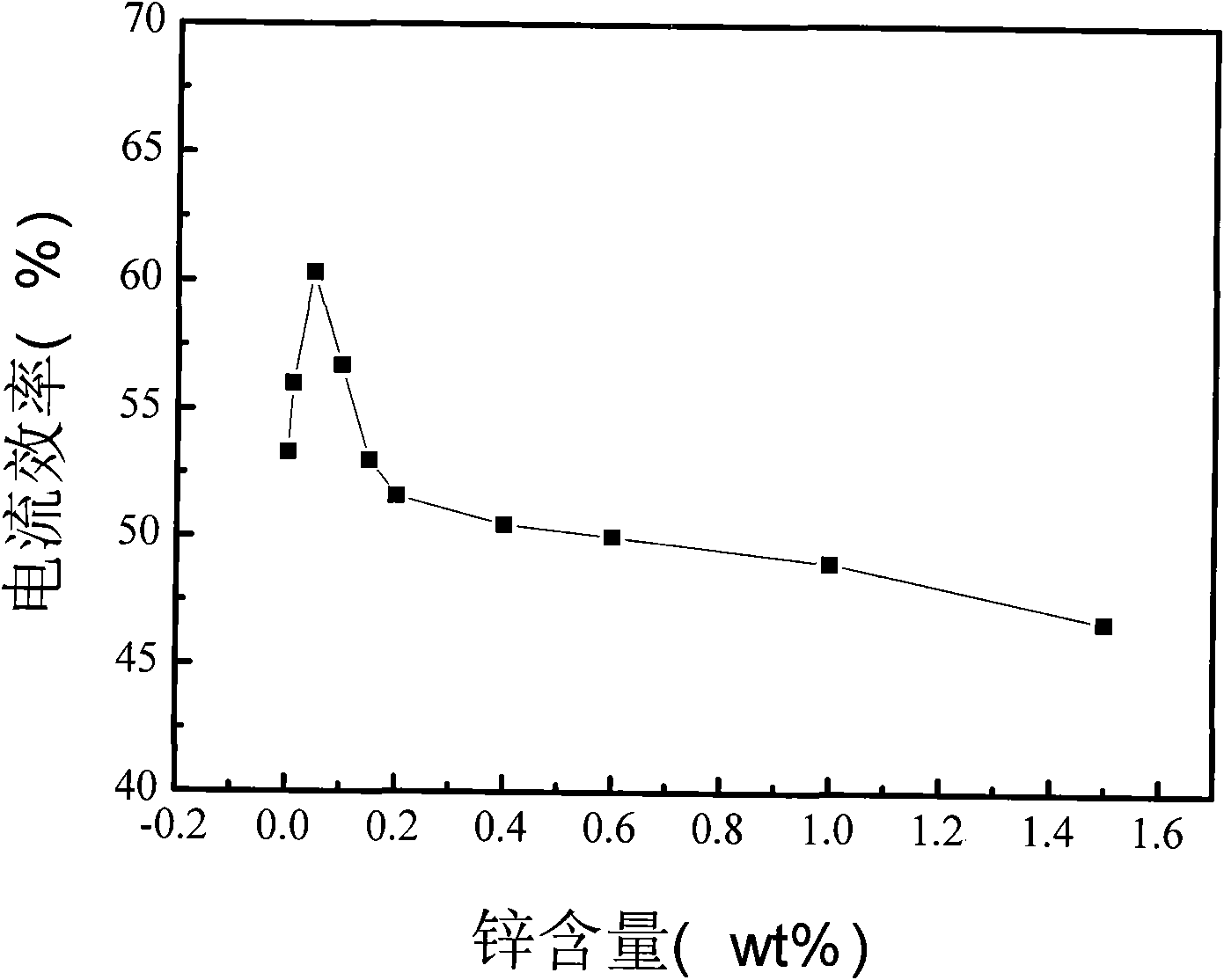

[0017] The sample without manganese added, the sample with manganese added and the high potential magnesium alloy sacrificial anode sample with zinc added by the method of the present invention will be described in detail below. By testing the electrical properties of the above-mentioned samples, it is shown that the electrical properties of the above-mentioned samples prepared by the method of the present invention all reach or exceed the provisions of the ASTM standard, especially the zinc-containing high-potential magnesium alloy sacrificial anode sample, whose electrical properties are better than the ASTM standard Provisions.

[0018] First, a high-potential magnesium alloy sacrificial anode without manganese was prepared. Among them, the raw material of the high potential magnesium alloy sacrificial anode without manganese and zinc is the crude magnesium directly produced by our company, and its chemical composition (wt%) is: Al≤0.006%, Si≤0.0078%, Mn≤ 0.015%, Fe≤0.0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com