Environmental-friendly type high-pressure three-plunger oil-free water pump

An environmentally friendly, plunger technology, applied to pumps, multi-cylinder pumps, pump components, etc., can solve the problems of inconvenient installation and use, inconvenient maintenance, environmental pollution, etc., and achieve convenient maintenance, simple structure, and high boosting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

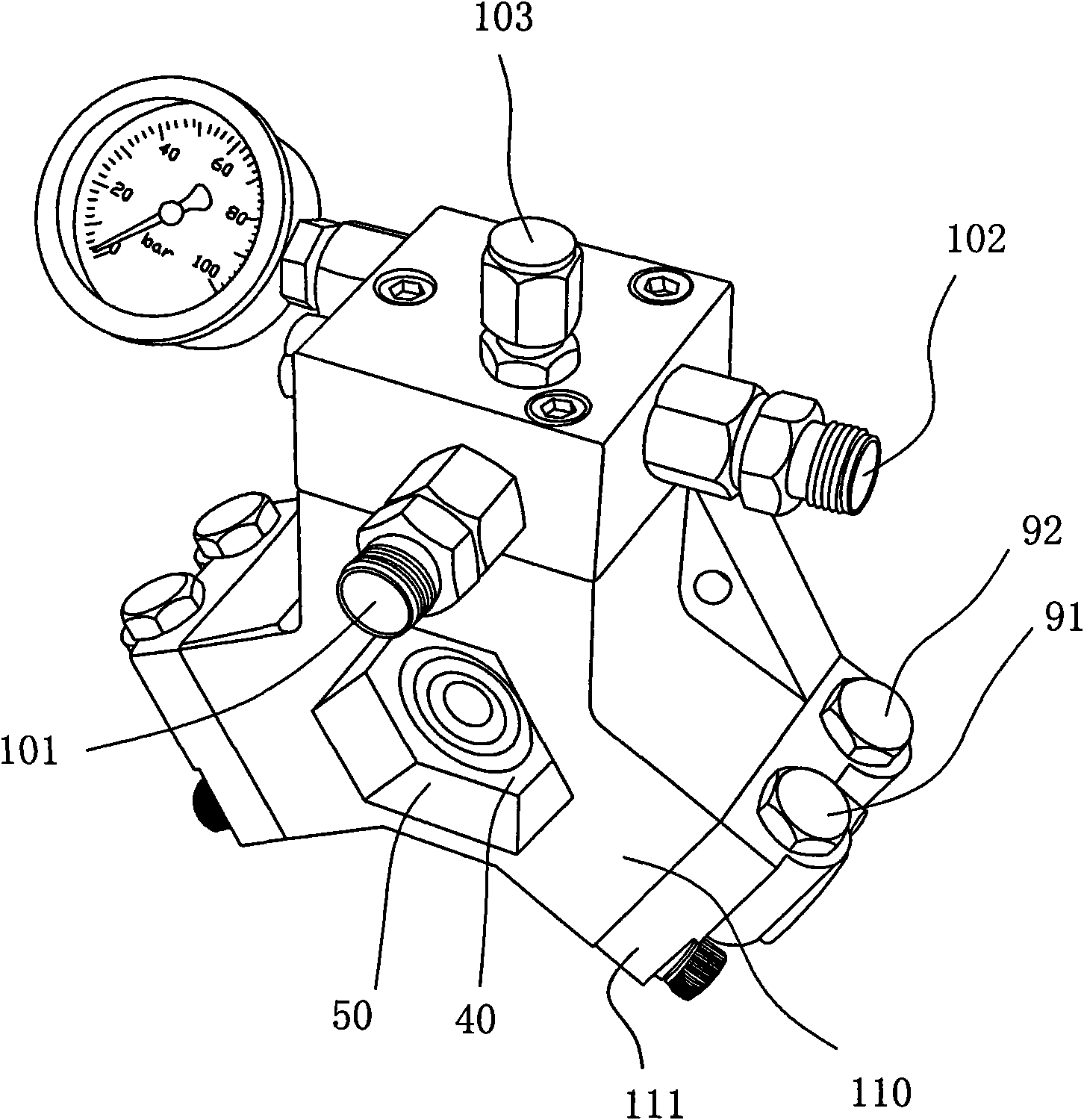

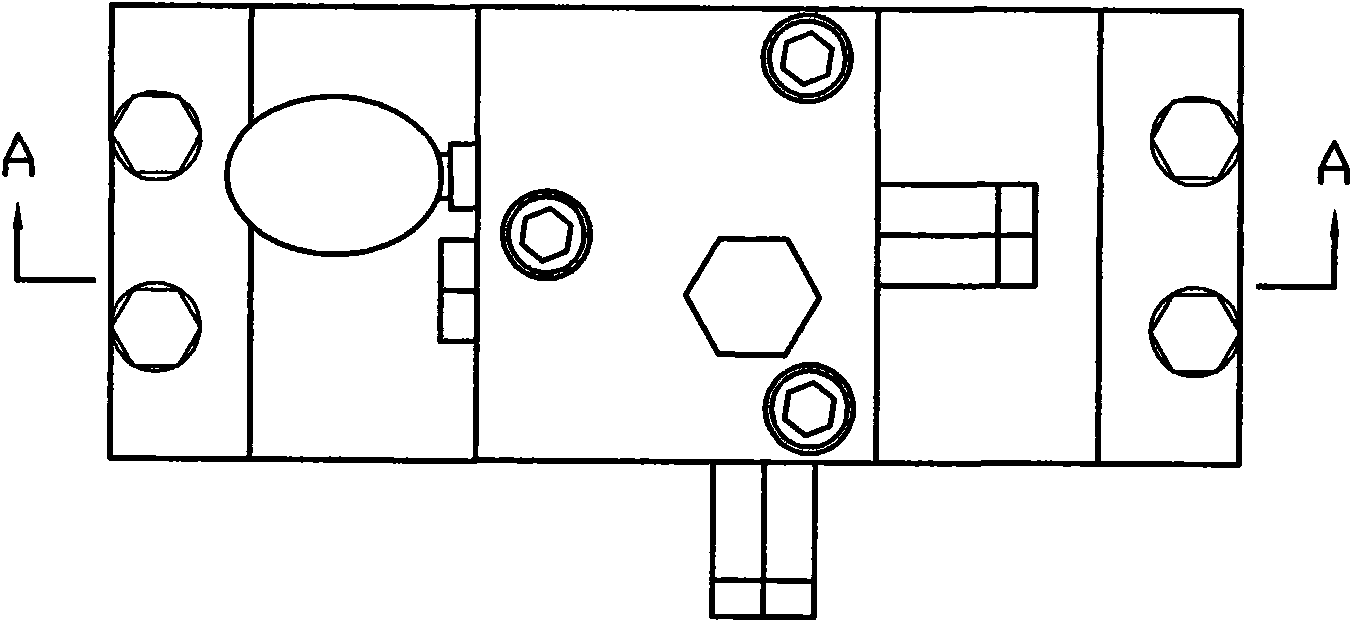

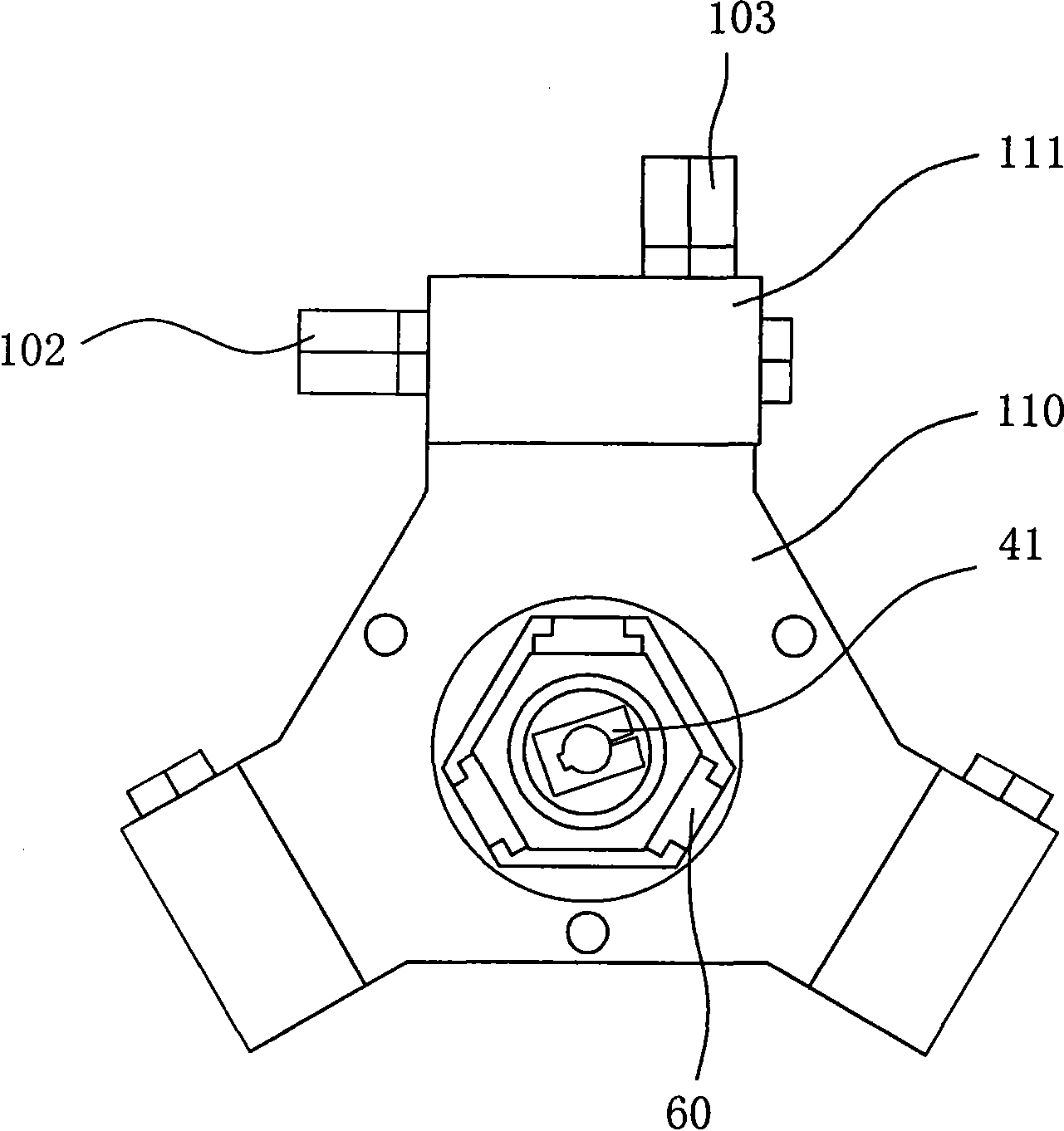

[0020] The present invention will be further described below with specific embodiment, see Figure 1-7 :

[0021] The environment-friendly high-pressure three-plunger oil-free water pump includes a pump body 110, a pump head 111 and a plunger set. A motor is installed on the pump body 110, and a motor shaft 10 protrudes from the motor. The motor shaft in the pump body 110 is 10 is covered with an eccentric seat 20, the upper end of the eccentric seat 20 is eccentrically arranged on the protruding shaft 21 with a bearing 30, and the bearing 30 is covered with an outer hexagon 40, and the outer hexagon 40 is arranged in the through hole 50 in the middle of the pump body 110. The outer surface of the hexagon 40 is evenly spaced with three spacers 60, and the three plunger holes radially evenly distributed between the spacers 60 and the pump head 111 are sequentially provided with a plunger 70 and a return spring 80, and the inside of the plunger 70 The end is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com