Enzyme immobilized electrode, fuel cell, electronic equipment, enzyme reaction utilization apparatus, and enzyme immobilized base

A technology of enzyme immobilization and fuel cells, applied in biochemical fuel cells, fuel cells, immobilized on or in inorganic carriers, etc., can solve problems such as inability to obtain energy conversion efficiency and consume chemical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Proteins are generally classified into three types: membrane proteins distributed in cell membranes, water-soluble proteins distributed in extracellular or intracellular solutions, and membrane-bound proteins in contact with cell membranes. Among them, membrane proteins and membrane-bound proteins are easily introduced into liposomes. Meanwhile, some proteins used for biofuels are usually distributed in intracellular or extracellular solution and have a relatively small amount of fat-soluble sites.

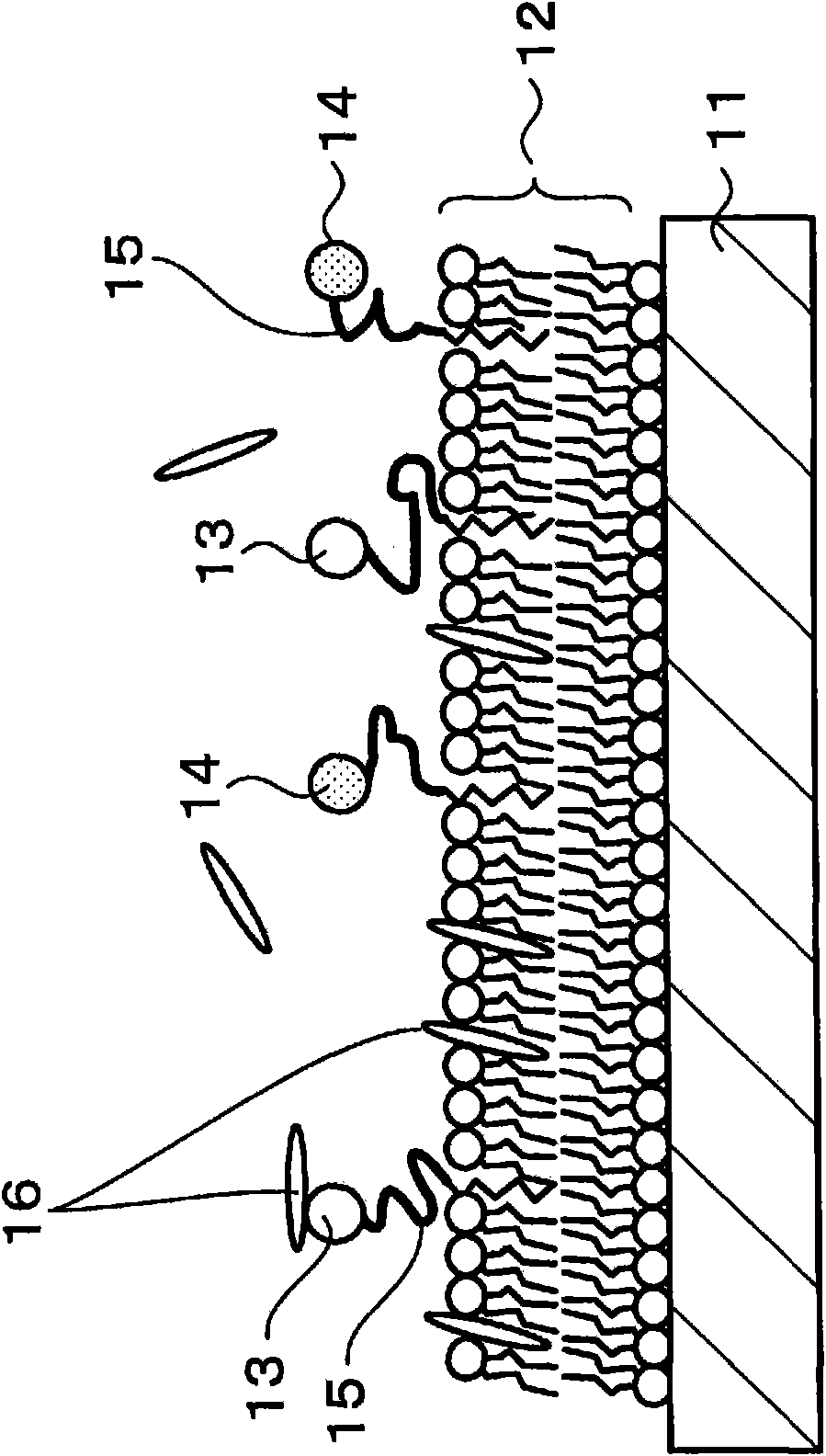

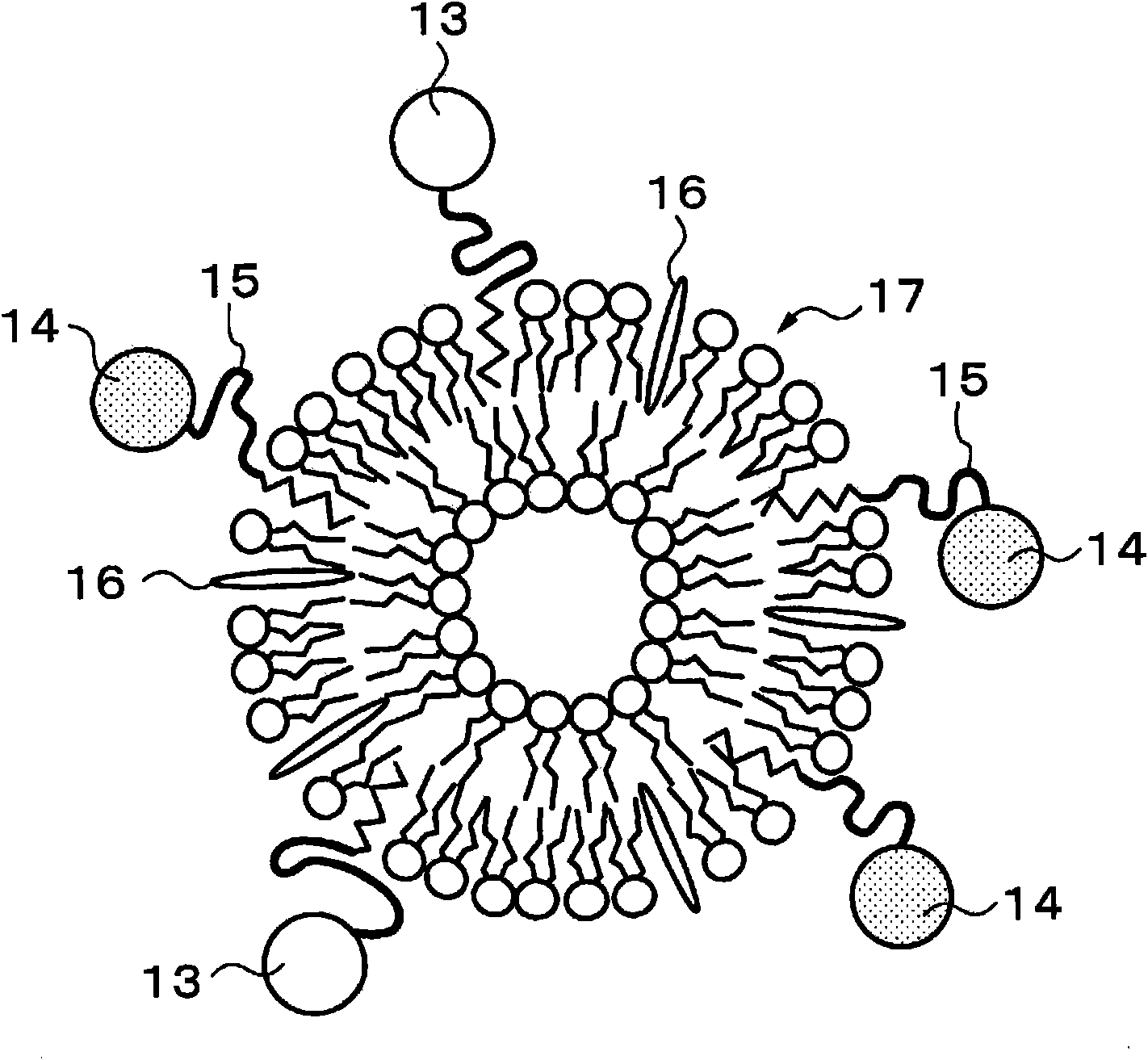

[0071] Meanwhile, as a configuration of phospholipid aggregates, spherical liposomes in the form of phospholipid bilayers are well known. Most membranes constituting living things are composed of liposomes, which are phospholipid aggregates, and they are very good reaction sites for keeping enzymes, proteins (especially membrane proteins) stable and highly active. Therefore, in Example 1, first, fat-soluble sites were introduced into the two enzymes 13 and 14, which were t...

Embodiment 2

[0081] As the electrode 11, a porous carbon electrode was used. The porous carbon electrode was activated with an ultraviolet (UV) ozone treatment unit to make the surface hydrophilic, and then immersed in a phosphate buffer containing about 500 μg / mL to 5 mg / mL enzyme and kept overnight. Then, rinse with phosphate buffered saline and dry. Thus, a porous carbon electrode having an enzyme as the intermediate layer 18 was obtained.

[0082] Next, liposomes including ANQ as electron mediator 16, diaphorase and glucose dehydrogenase as enzymes 13 and 14, and NADH as coenzyme were added dropwise to the porous carbon with enzyme as intermediate layer 18. electrodes and then dry. Thus, an enzyme-immobilized electrode was produced. As a control, an enzyme-immobilized electrode was manufactured by activating a porous carbon electrode using a UV ozone treatment device to make the surface hydrophilic, and then dropwise adding a liposome solution containing an enzyme or the like (Compa...

Embodiment 3

[0088] As the electrode 11, a porous carbon electrode was used. The porous carbon electrode was activated with an ultraviolet (UV) ozone treatment unit to make the surface hydrophilic, and then immersed in a phosphate buffer containing about 500 μg / mL to 5 mg / mL enzyme and kept overnight. Then, rinse with phosphate buffered saline and dry. Thus, a porous carbon electrode having an enzyme as the intermediate layer 18 was obtained.

[0089]Next, ANQ as electron mediator 16, diaphorase and glucose dehydrogenase as enzymes 13 and 14, NADH as coenzyme, PLL as polycation, PLL as polyanion, and The solution of PAAcNa was added dropwise onto the porous carbon electrode with the enzyme as an intermediate layer 18 and then dried. Thus, an enzyme-immobilized electrode was produced. As a control, the enzyme-immobilized electrode of Comparative Example 1 was used to compare electrochemically. In the test, a potentiostatic test and a cyclic voltammetry test at 0.1 V were performed using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com