Integrated surface acoustic wave wireless pressure sensor applied to TPMS

A pressure sensor and surface acoustic wave technology, applied in the field of wireless pressure sensors, can solve the problems of inability to realize simultaneous detection of tire temperature and pressure, single function of wireless pressure sensor, etc., to improve the performance of signal-to-noise ratio, reduce noise between reflection peaks, Sensitivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

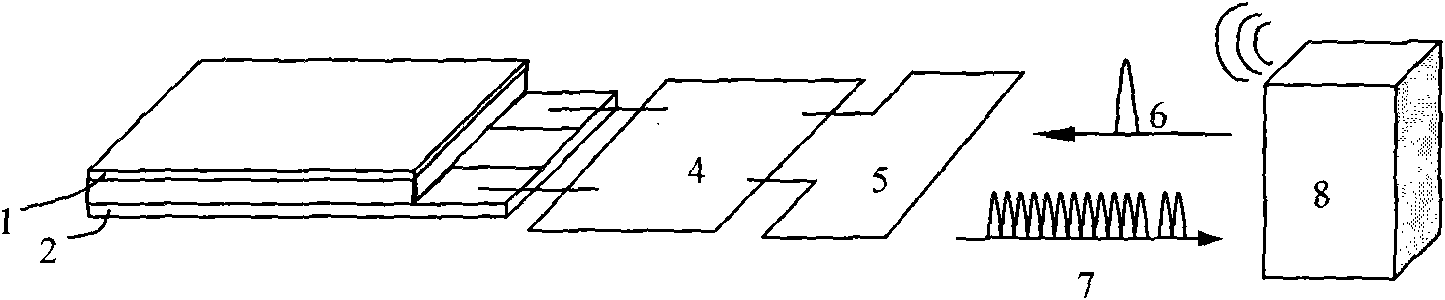

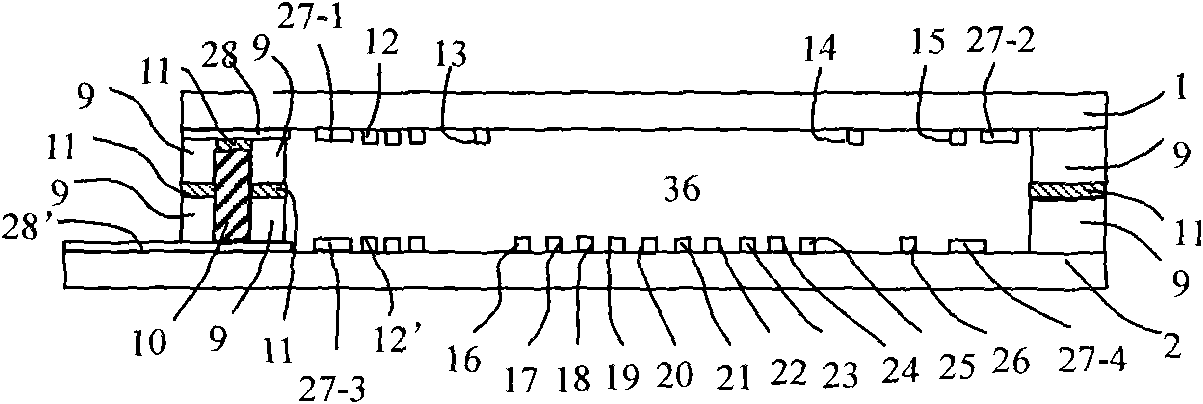

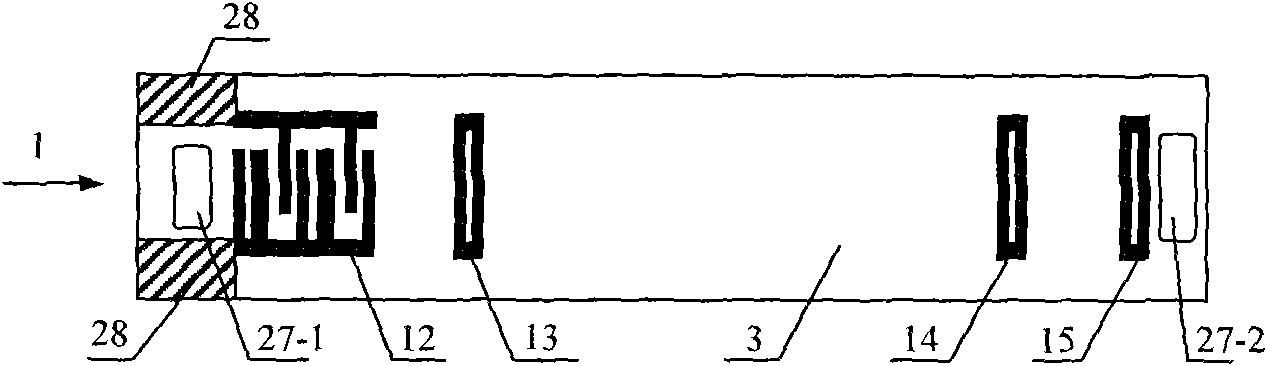

[0047] refer to Figure 1aand b, making a SAW wireless pressure sensor for integrated temperature detection and electronic label applied to TPMS, including: first SAW reflective delay line 1 and second SAW reflective delay line 2, nickel conductive pillar 10, JSR film 9, The conductive glue 11 and the impedance matching network 4 between the SAW wireless pressure sensor and the wireless antenna 5 . The electromagnetic wave signal 6 emitted from the reading unit 8 is received by the wireless antenna 5, converted into SAW by the single-phase unidirectional transducer with the width of the control electrode, and propagated along the surface of the piezoelectric substrate 3 And it is partially reflected back to the control electrode width single-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com