Composite resonance sound absorption device of tube bundle perforated plate

A technology of resonant sound absorption and perforated plate, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of insufficient low-frequency sound absorption, and achieve the effect of increasing sound absorption coefficient, increasing sound resistance, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

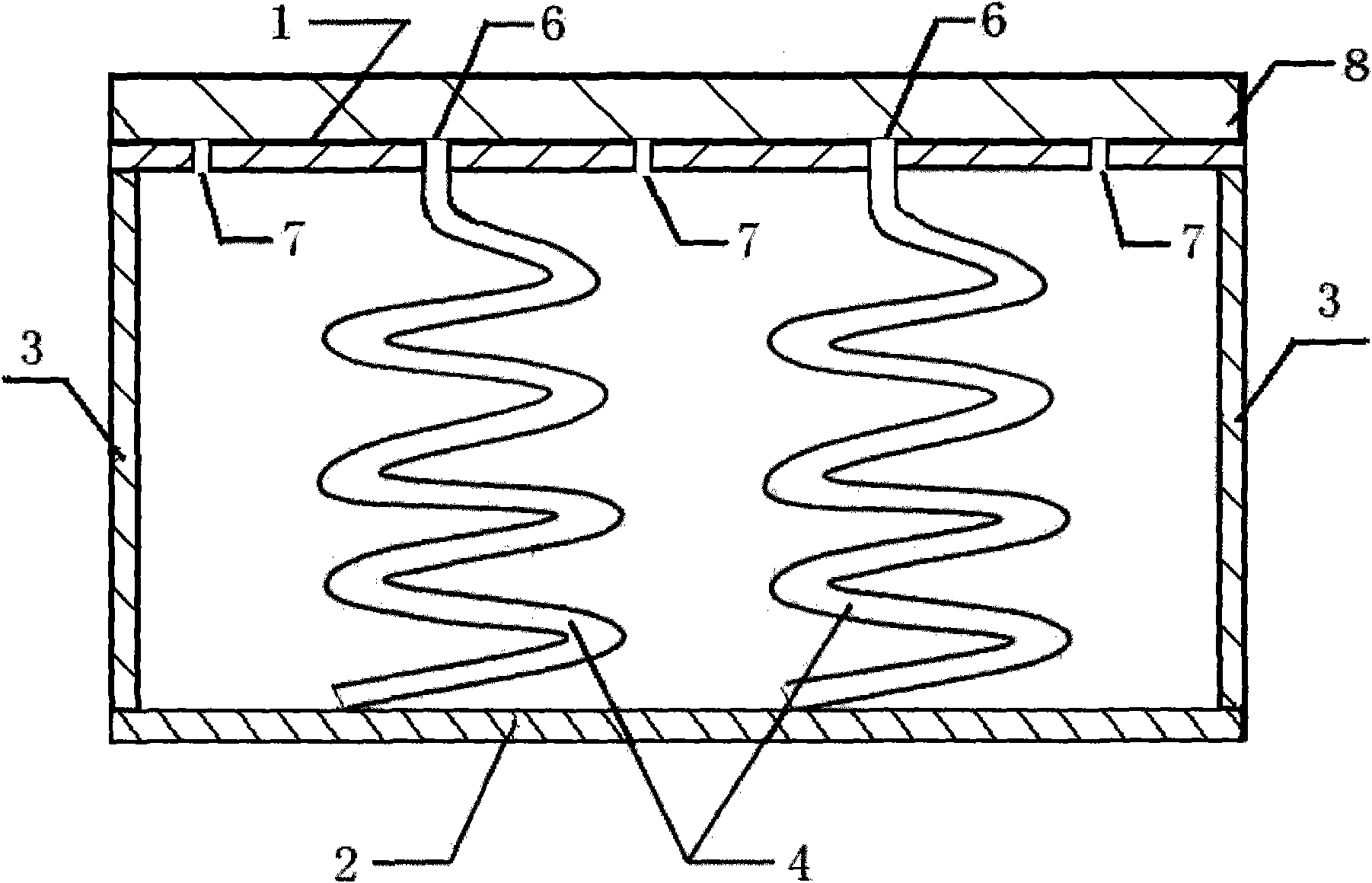

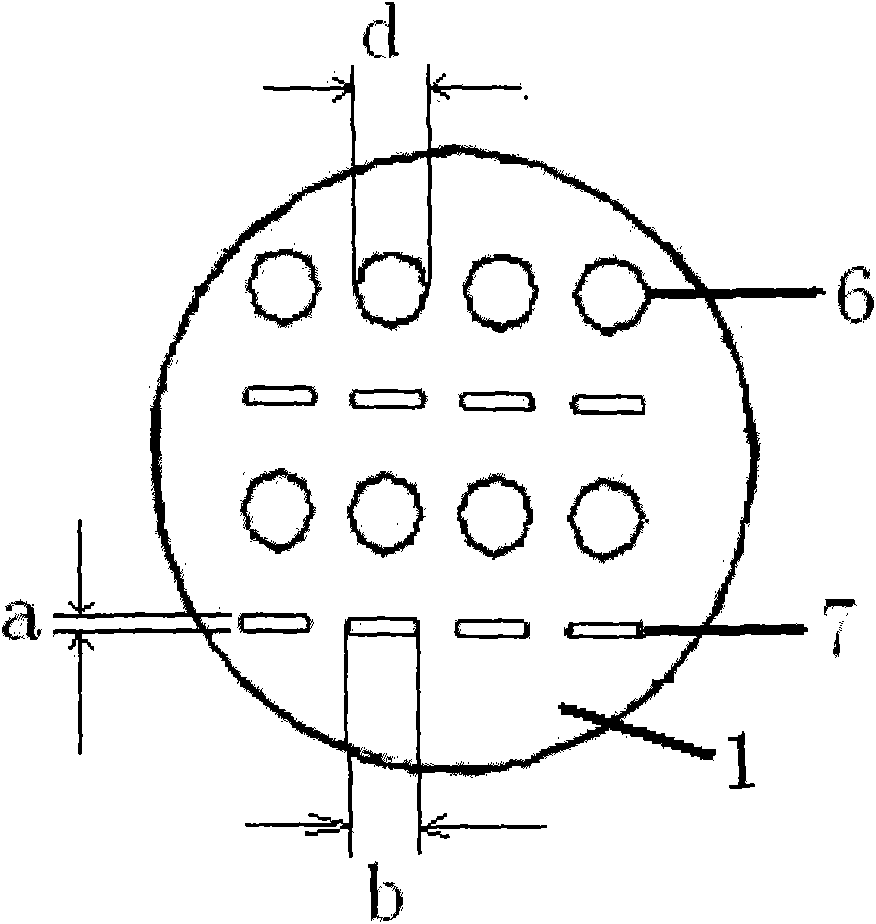

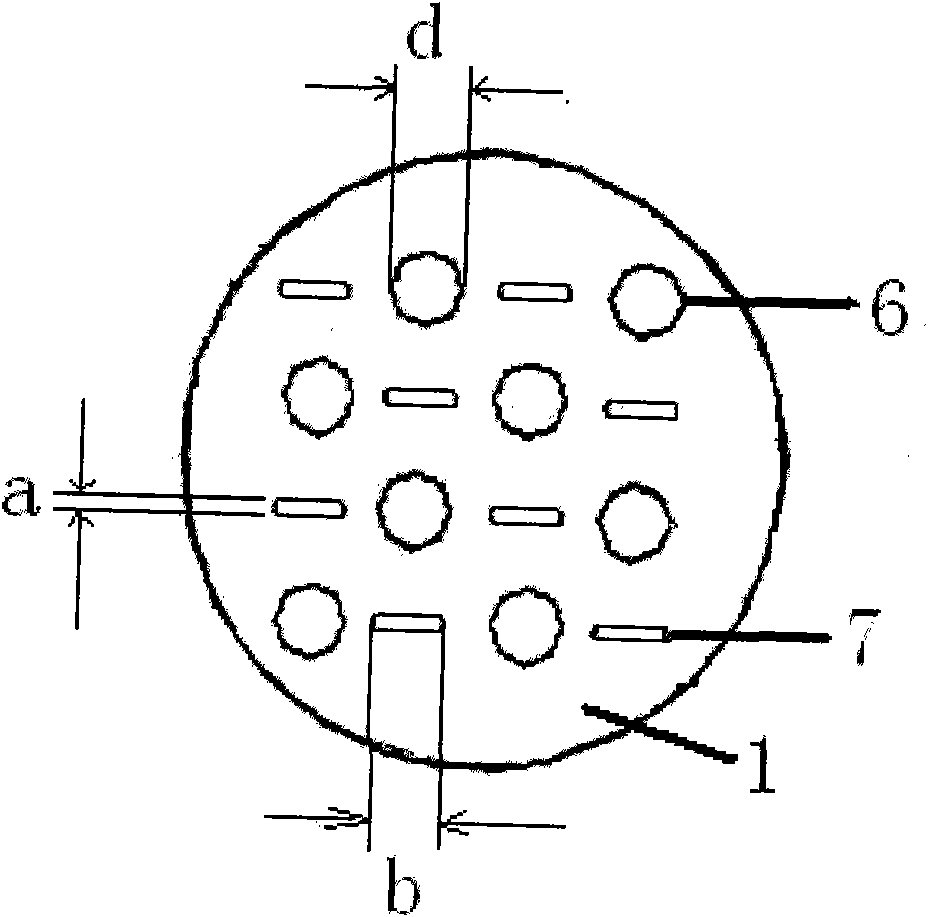

[0037] refer to figure 1 , the present embodiment makes a tube bundle perforated plate composite resonance sound-absorbing device, which is a closed cavity composed of a perforated plate 1, a back plate 2 made of stainless steel plate and a side plate 3 made of stainless steel plate, the closed cavity Cavity depth D, for example, D is 10mm, 100mm, 200mm, 300mm, 500mm, 1000mm or 1500mm; the perforated plate is a circular stainless steel plate with a diameter of 100mm and a thickness of 1.8mm. The perforated plate is provided with micro-slits and holes. The width of the micro-slit is 0.04mm, the length of the micro-slit is 3.6mm, and the diameter of the hole is 1.6mm; wherein, the penetration rate ρ of the micro-slit 7, for example, ρ is 0.1%, 1%, 6%, 10%, 20% or 30%. Wherein, the diameter of the hole 6 is 1.6mm, and the perforation rate σ of the hole 6, for example, σ is 0.1%, 1%, 6%, 10%, 20% or 30%. The micro-slits 7 on the perforated plate 1 are arranged in a regular square...

Embodiment 2

[0053] In the standing wave measuring tube, the experimental research on the noise elimination mechanism of the tube bundle perforated plate composite resonance sound absorption device without laying sound-absorbing cotton was completed, and the resonance of the tube bundle perforated plate composite resonance sound absorption device and the perforated plate (including micro-slits and holes) was compared and measured The sound absorption characteristics of the sound-absorbing structure determine the influence of the pipe length, cavity depth, and perforation rate structural parameters on its acoustic performance, such as Figure 5 shown.

[0054] Parameters: tube bundle diameter: 1.6mm, perforation rate: 5%, micro-slit length: 1.8mm, micro-slit width: 0.05mm

[0055] Image 6 The sound absorption characteristics under the following 10 different conditions were compared

[0056] 1) The length of the tube bundle is 350mm, and the cavity depth is 200mm

[0057] 2) The length o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com