Radial vibration piezoelectric transformer and preparation method thereof

A piezoelectric transformer and radial vibration technology, applied in the field of piezoelectric transformers, can solve the problems of not considering how to eliminate, not taking into account the influence of the driving voltage waveform on the depolarization of the primary monolith, and increasing the loss of the transformer, so as to reduce the Insulation coating, the effect of eliminating heat generation and reducing insulation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation method of a radial vibration piezoelectric transformer provided in this embodiment includes the following steps:

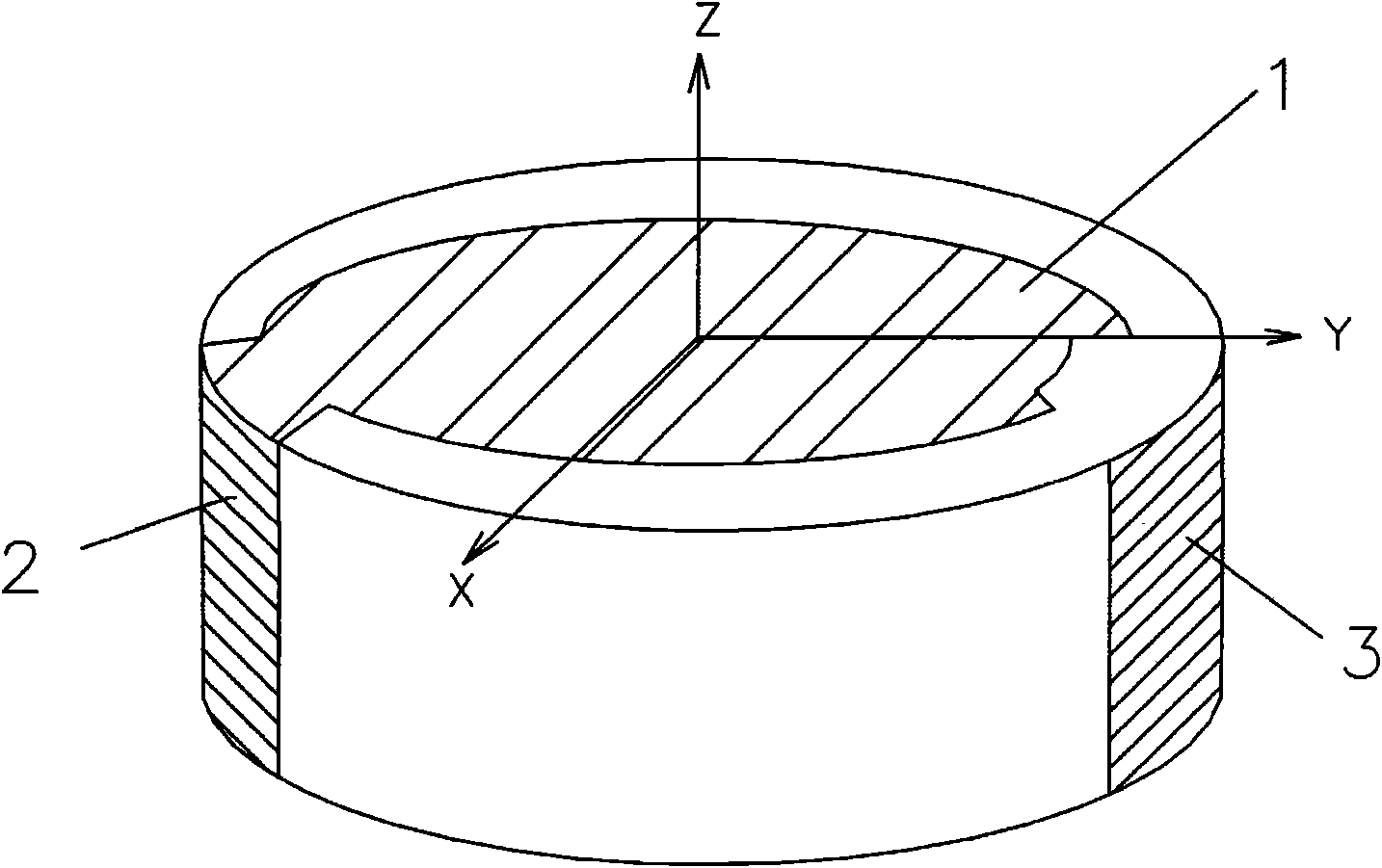

[0052] 1. Transformer structure

[0053] 1. Preparation method of circular (or regular polygonal) ceramic monolithic electrode

[0054] Take the preparation method of a circular ceramic monolithic electrode as an example.

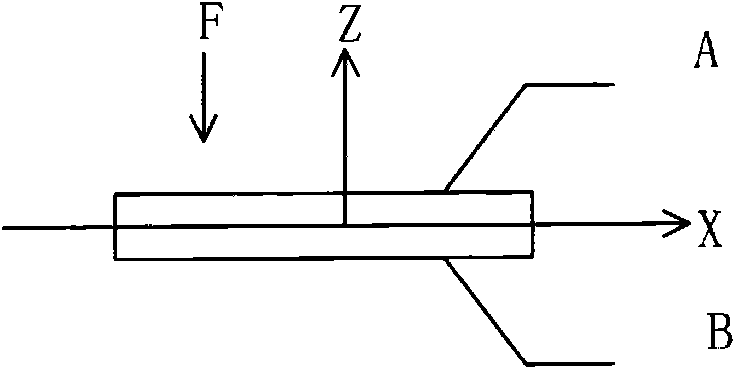

[0055] 1.1 Class AB monolithic

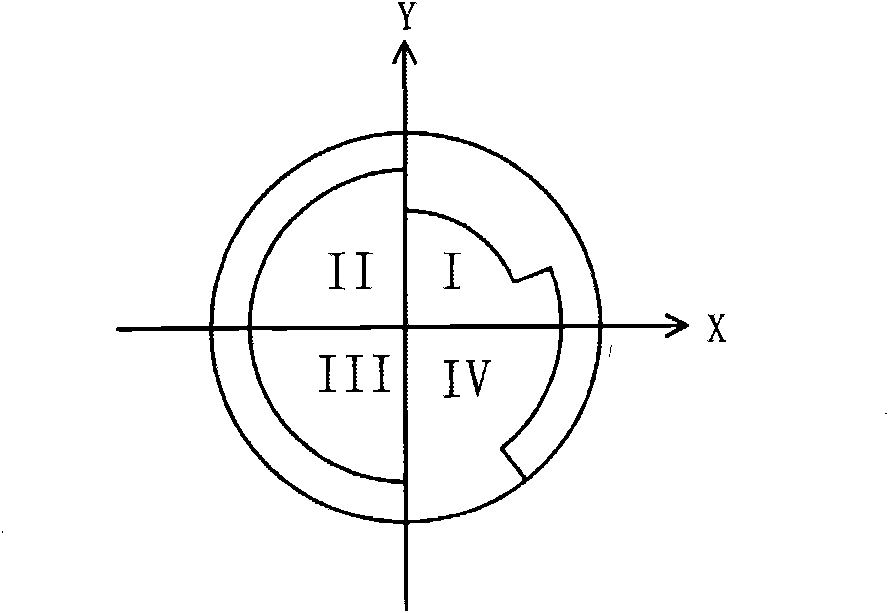

[0056] As shown in Figure 2, it is a front view of a class AB monolithic sheet, and the upper and lower surfaces are A and B respectively. Divide the single piece into four quadrants I, II, III, and IV. The surface electrode on the A surface of the upper surface is concentric with the circular surface, and the radius is smaller than that of the A surface. There is a radial protrusion in the IV quadrant and a radial depression in the I quadrant. The irregular circles are formed by silver, such as image 3 As shown; the B side of the lower surface is opposite to the A side, the radial co...

Embodiment 2

[0164] The design requirements for the piezoelectric transformer required in this embodiment are as follows:

[0165] Input voltage V 1 =140V;

[0166] output voltage V 2 =10V;

[0167] Rated output power P=20W;

[0168] Rated load R=5Ω;

[0169] Working temperature -40°C-+50°C;

[0170] In the range of 0.4P-1P;

[0171] The input voltage and the input current are in the same phase or the phase difference is π;

[0172] Phase error <5°.

[0173] According to the preparation method of the radial vibration piezoelectric transformer provided by the present invention, the solution is as follows:

[0174] m 1 / m 2 = 1 / 14,k m =1, that is, the primary is composed of ceramic monoliths in series, and the secondary is composed of ceramic monoliths in parallel; Ka=2.18, when the radius of ceramic monoliths a=0.013m, the piezoelectric transformer wave number K=167; so ω=Kv=2π× 89×10 3 l / sec; δ=1.39, N=0.28; m 1 τ 1 / m 2 τ 2 =1.13; m 2 / τ 2 =6086l / m,τ 2 =0.00023m,τ 1 =...

Embodiment 3

[0183] The design requirements of the piezoelectric transformer in this embodiment are as follows:

[0184] Input voltage V 1 = 42.5V;

[0185] output voltage V 2 =85V;

[0186] Rated output power P=36W;

[0187] Rated load R=200Ω;

[0188] In the range of 130Ω-260Ω, without adjusting the working frequency;

[0189] Output power ≈P±5%P;

[0190] Constant current in the range of 0~40Ω, deviation <5%.

[0191] According to the preparation method of the radial vibration piezoelectric transformer provided by the present invention, the solution is as follows:

[0192] m 1 / m 2 = 2 / 1,k m =1, the primary is composed of ceramic monoliths in parallel, and the secondary is composed of ceramic monoliths in series; Ka=2.088, when a=0.0175m, K=119.3, so ω=2π×64.8×10 3 l / sec, δ=0.401; N=2.004×10 -3 ;m 1 τ 1 / m 2 τ 2 = 1, m 2 / τ 2 =333l / m;τ 2 =0.003m;τ 1 =0.0015m; m 1 = 2, m 2 = 1, a = 0.0175m; R i =1 / 5×R=40Ω; f=64.8KHz.

[0193] The characteristics of the prepared pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com