Membrane electrode for proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in battery electrodes, fuel cell parts, circuits, etc., can solve the problems of catalyst waste, ineffective utilization, complex process, etc., to reduce costs, reduce load capacity, enhance The effect of battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

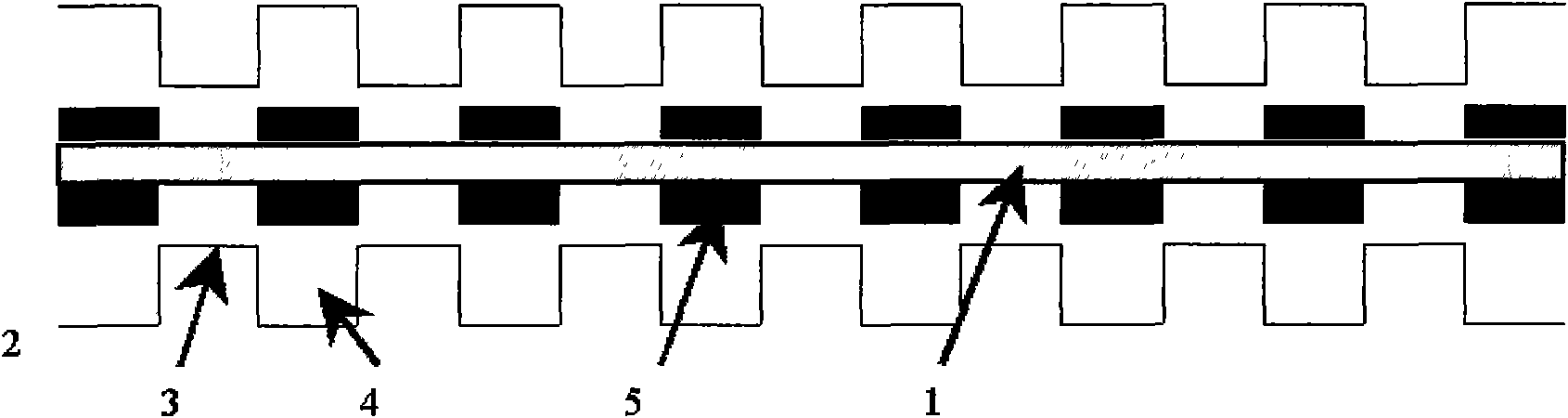

[0024] Prepare a strip-shaped flow field mold, make the strip-shaped hollow part of the mold correspond to the gas channel part of the flow field, and align and fix the mold with the proton exchange membrane. 5% Nation solution and 20% Pt / C are ultrasonically oscillated in a mass ratio of 1:3, and mixed evenly, and then deionized water and glycerin are added to it, and after being evenly mixed by ultrasonic waves, a small amount of 5% NaOH solution to form an ink-like solution, spray the above solution directly onto the Na-type PEM, and dry it at 160-190°C; use the same method to spray the ink-like solution on the other side of the PEM, and dry it to form a thin layer CCM; make the CCM in 0.5mol / L H 2 SO 4 Boiling for 1 hour, the sodium-type PEM is transformed into hydrogen-type PEM, then washed with deionized water, and dried. A strip-shaped catalyst layer is formed on the proton exchange membrane.

Embodiment 2

[0026] Prepare a strip-shaped flow field mold, make the strip-shaped hollow part of the mold correspond to the gas channel part of the flow field, and align and fix the mold with the proton exchange membrane. Use a primary balance to weigh 20 mg of catalyst Pt and 20 mg of IrO2, add 1.6 g of 5% Nation solution, and oscillate ultrasonically for 40 minutes to mix evenly, then add deionized water and glycerin to it, and after ultrasonically mix evenly, add a small amount of 5 % NaOH solution to form an ink-like solution. Spray the above solution directly onto the Na-type PEM and dry it at 160-190°C; use the same method to spray the ink-like solution on the other side of the PEM and dry it to form a thin film. layer CCM; make the CCM in 0.5mol / L H 2 SO 4 Boiling for 1 hour, the sodium-type PEM is transformed into hydrogen-type PEM, then washed with deionized water, and dried. A strip-shaped catalyst layer is formed on the proton exchange membrane.

Embodiment 3

[0028] A layer of Pt with a thickness of 500nm is deposited on the entire surface of the film by plasma sputtering method. Then prepare the strip-shaped flow field mold, make the strip-shaped hollow part of the mold correspond to the gas channel part of the flow field, and align and fix the mold with the proton exchange membrane. Then use the plasma sputtering method to deposit a layer of Pt with a thickness of 500nm on the surface of the film, then impregnate the Nation / C / isopropanol solution on the surface of the Pt, and then sputter the Pt after drying. The thickness of the catalytic layer corresponding to the channel is 3-6 μm, and the loading of Pt is 0.043 mg / cm 2 , while the corresponding catalyst loading on the membrane at the raised part of the flow field is 25% of that at other parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com