Porous, non-degradable implant made by powder molding

An implant, a molding technique, used in the field of porous implants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] Preparation of Slurry A

[0148] A slurry was made with tantalum nanoparticles and irregularly shaped polyethylene beads. Tantalum pellets were purchased from H.C. Starck. Polyethylene beads were purchased from Impag (Microscrub, D50 150 μm). The D50 particle size of the tantalum particles is 100 nm. The slurry contained 500 g tantalum, 200 g polyethylene beads, wetting agent (BykP-104) and ethanol (commercially available from Merck). The granules were mixed with 100 g of humectant and stirred for about 20 min. Suspend 200g polyethylene beads in 200g ethanol for 10min and add to the tantalum pellets. The slurry was homogenized with a conventional stirrer for 1 h.

Embodiment 2

[0150] Preparation of slurry B

[0151] A slurry was made with silica and polyethylene beads. Silica was purchased from Degussa (Aerosil R972) and polyethylene beads were purchased from Impag. Similar to Example 1, a slurry was prepared with 200 g of silica as follows: 100 g of acetone was added, stirred for about 1 h, and then 150 g of polyethylene beads were added. The slurry was homogenized for about 90 min more.

Embodiment 3

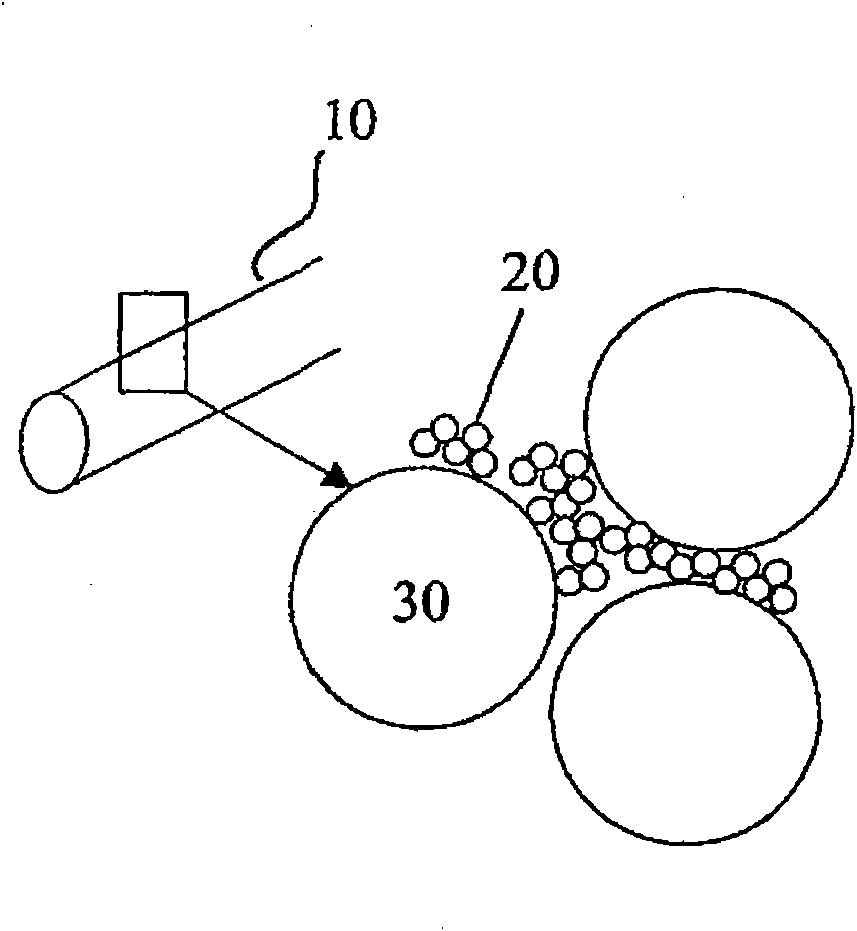

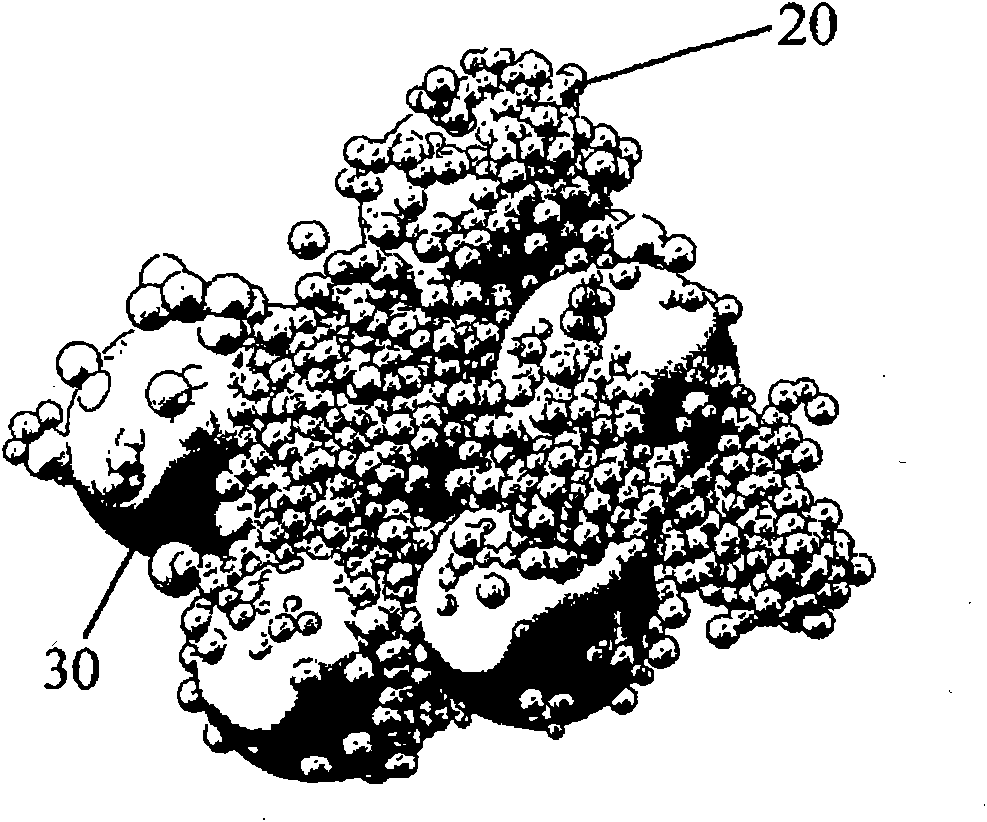

[0153] Molding disc-shaped implants from Slurry A: rapid heating

[0154] A standard cylindrical hollow mold made of stainless steel with an inner diameter of 3 cm and a length of 8 cm was used. The mold was filled with Slurry A to 4 / 5 full volume and compacted using a standard spring molding machine to form a green body. A compaction pressure of 50 MPa was then applied for 100 s, and the cycle was repeated 2 more times. The green body is disc-shaped, with a diameter of 2.8 cm and a height of 4 cm. Dry for another 1 h at room temperature and then put into a standard sintering furnace. The green body was sintered as follows: the temperature was raised at a heating rate of 20 K / min, the temperature was kept at 400° C. for 4 hours, and then cooled to room temperature within 20 hours.

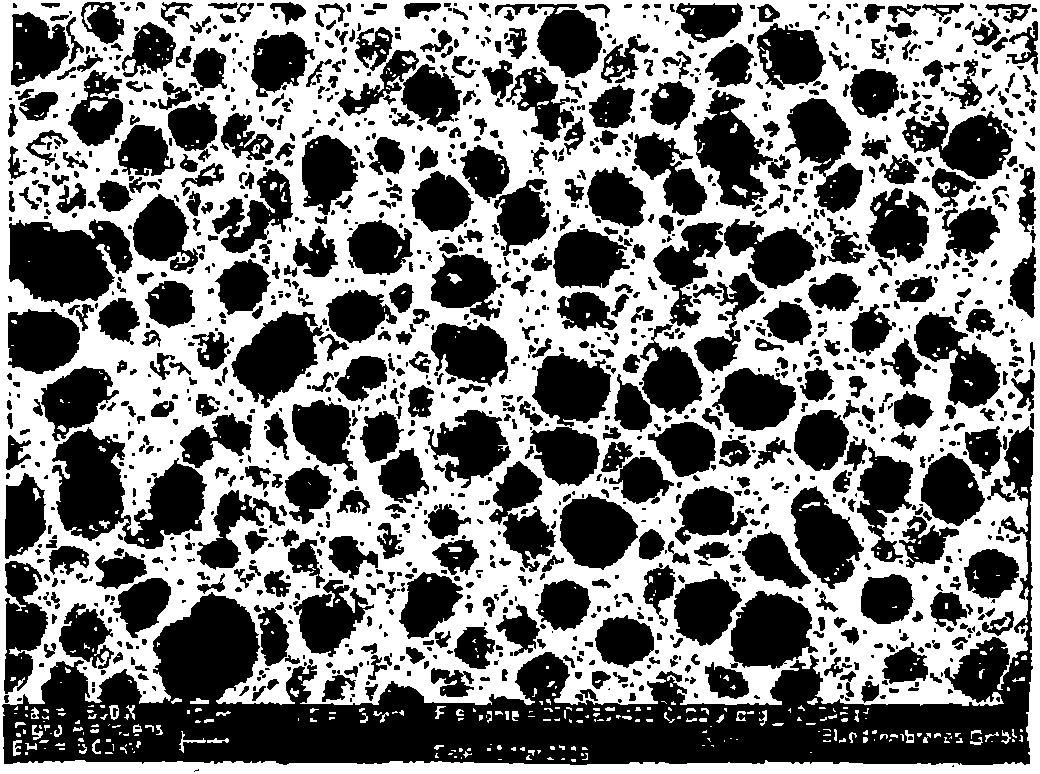

[0155] The molded body was cut to analyze the pore structure introduced by the polyethylene bead filler. The molded body has a regular surface structure macroscopically. The microstructu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com