HT-02 type ship dressing coat

A HT-02, 1.HT-02 technology, applied in the field of HT-O2 marine dressing coating, can solve the problems of shortened service life, rust, etc., and achieve the effect of comfortable walking, soft surface and changeable colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] HT-O2 marine dressing coating is composed of epoxy resin, curing agent, wear-resistant filler and thinner. The ratio of each component is as follows in terms of weight ratio:

[0018] Specific dosage ratio

[0019] material name

Packing Specifications

Laying weight

Laying consumption

epoxy resin

13.5kg / drum

1116g

0.0827 barrels

Hardener

4.5kg / drum

372g

0.0827 barrels

[0020] Wear-resistant filler

20kg / bag

988g

0.0494 packs

Thinner

10kg / barrel

100g

0.01 barrel

[0021] In the above technical solution, the epoxy resin is produced by Shanghai Shengxing Resin Coating Co., Ltd.

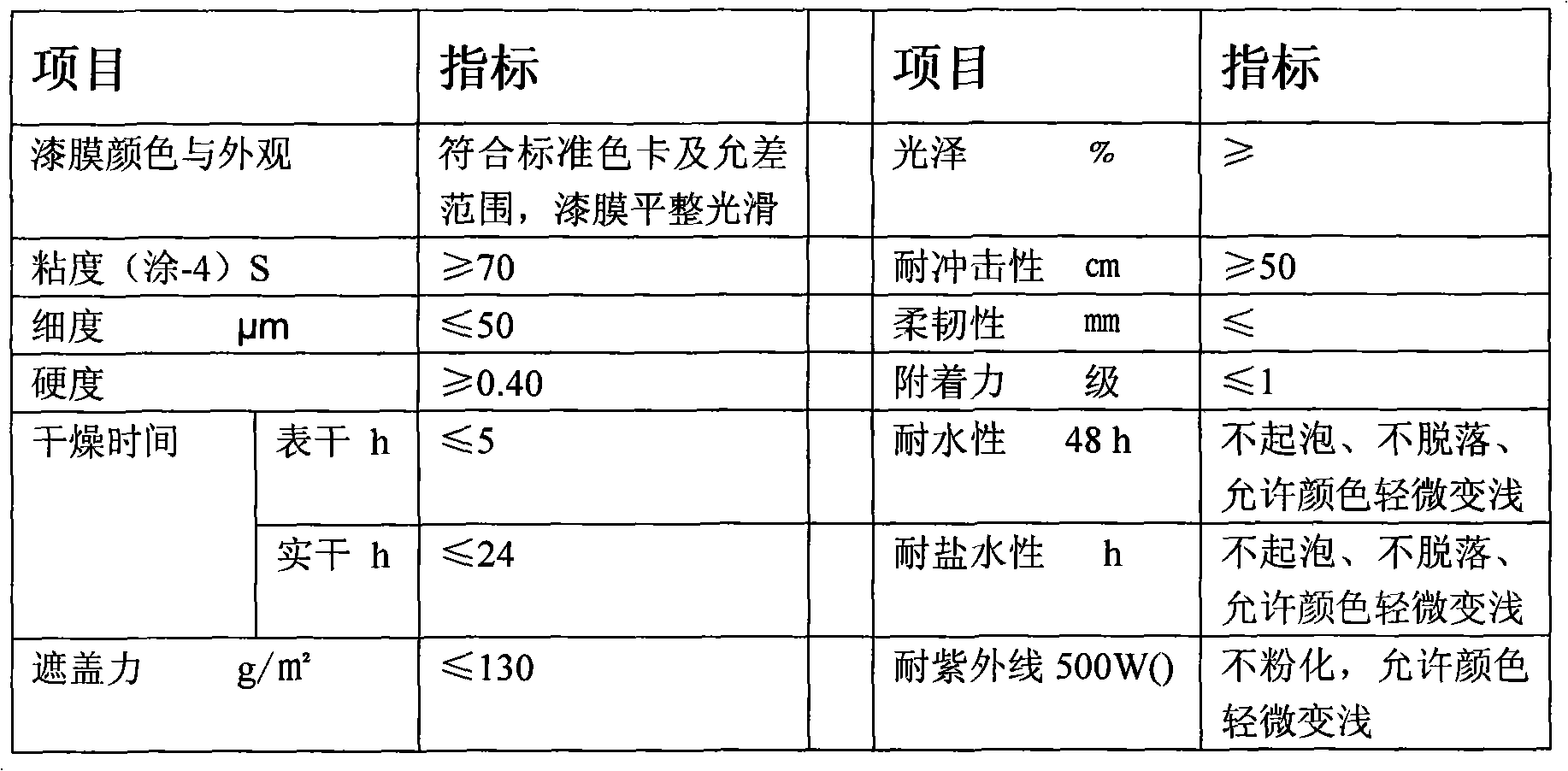

[0022] The specific product models and technical indicators are as follows:

[0023] Product model name: H80-03 bright green epoxy floor paint (package)

[0024] Production batch number: 03092307, 2308 Executive standard: SXJS-03-009-052

[0025] Packing specification: A 13....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com