Organosilicon insulating impregnating varnish and preparation method thereof

A technology of insulating impregnating varnish and silicone, applied in coating and other directions, can solve problems such as high viscosity, environmental pollution, and harm to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

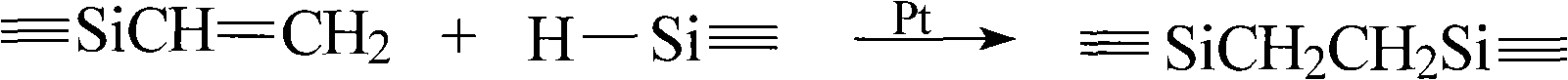

Method used

Image

Examples

Embodiment 1

[0024] 1) Synthesis of polymethylphenylvinylsiloxane: dissolve 65 parts of methyltrimethoxysilane, 280 parts of diphenyldimethoxysilane, and 100 parts of vinyltrimethoxysilane in 260 parts of ethanol , slowly drop 85 parts of deionized, and adjust the pH to 3.5 with hydrochloric acid, after 2 hours of hydrolysis reaction at 50°C and 7 hours of condensation reaction at 80°C, solution 1# was obtained; 40 parts of hexamethyldisiloxane and 5 parts Dissolve deionized water in 20 parts of ethanol, add a certain amount of hydrochloric acid, adjust the pH to 3.0, and hydrolyze at 80°C for 1 hour to obtain solution 2#; slowly pour solution 2# into solution 1#, react at 70°C for 8 hours, and then let it stand Layered to get the lower layer of oil, which is polymethylphenyl vinyl siloxane;

[0025] 2) Synthesis of vinyl polyhedral oligomeric silsesquioxane: dissolve 100 parts of vinyltrimethoxysilane in 260 parts of ethanol, slowly add 40 parts of deionized water and a certain amount of ...

Embodiment 2

[0029] 1) Synthesis of polymethylphenylvinylsiloxane: dissolve 80 parts of methyltrimethoxysilane, 340 parts of diphenyldimethoxysilane, and 120 parts of vinyltrimethoxysilane in 300 parts of ethanol , slowly add 90 parts of deionized water and a certain amount of hydrochloric acid dropwise, adjust the pH to 3.0, after hydrolysis at 30°C for 3 hours and condensation reaction at 70°C for 9 hours, solution 1# is obtained; 50 parts of hexamethyldisiloxane and Dissolve 7 parts of deionized water in 35 parts of ethanol, add a certain amount of hydrochloric acid, adjust the pH to about 4, and hydrolyze at 50°C for 2 hours to obtain solution 2#; slowly pour solution 2# into solution 1#, and react at 80°C for 6 hours After standing still, the lower layer oily substance is obtained, which is polymethylphenyl vinyl siloxane.

[0030] 2) Synthesis of vinyl polyhedral oligomeric silsesquioxane: dissolve 110 parts of vinyltrimethoxysilane in 290 parts of ethanol, slowly add 45 parts of dei...

Embodiment 3

[0034] 1) Synthesis of polymethylphenylvinylsiloxane: dissolve 90 parts of methyltrimethoxysilane, 390 parts of diphenyldimethoxysilane, and 135 parts of vinyltrimethoxysilane in 300 parts of ethanol , slowly add 100 parts of deionized water and a certain amount of hydrochloric acid dropwise, adjust the pH to 2.8, after 2.5 hours of hydrolysis at 40°C and 8 hours of condensation reaction at 75°C, solution 1# is obtained; 55 parts of hexamethyldisiloxane and Dissolve 8 parts of deionized water in 40 parts of ethanol, add a certain amount of hydrochloric acid, adjust the pH to 6.0, and hydrolyze at 30°C for 3 hours to obtain solution 2#; slowly pour solution 2# into solution 1#, and react at 75°C for 7 hours Standing and stratifying to obtain the oily substance in the lower layer, which is polymethylphenyl vinyl siloxane;

[0035] 2) Synthesis of vinyl polyhedral oligomeric silsesquioxane: Dissolve 130 parts of vinyltriethoxysilane in 260 parts of ethanol, slowly add 40 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com