Petrol engine supercharger bypass valve

A supercharger and bypass valve technology, which is applied in the direction of machines/engines, valve details, valve devices, etc., can solve the problems of material, structure, and reliability that cannot meet the requirements, synchronous wear of pin 1 and rocker arm 2, and low-speed engine torque Poor and other problems, to avoid free rotation, improve reliability, improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

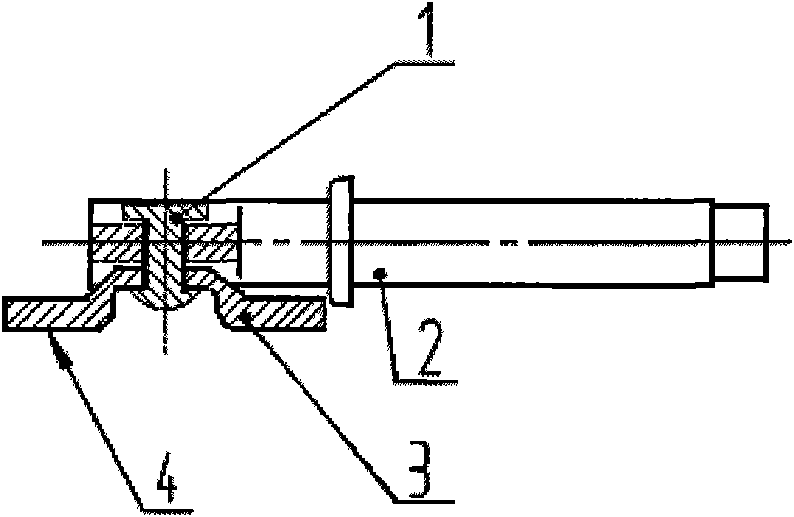

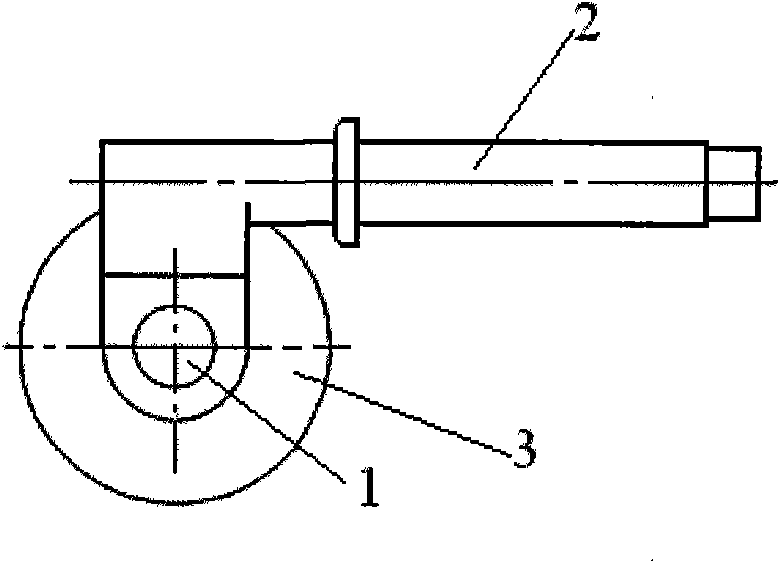

[0038] Such as image 3 , Figure 4 with Figure 5 As shown, the cross-section of the valve connection boss 9 in the present invention is a waist circle, and the shape of the rocker arm connection hole 10 is matched with the waist circle.

[0039] Such as image 3As shown, the rocker arm 2 and the bypass valve 3 are made of new high-temperature-resistant stainless steel investment casting precision casting, and the gasket 5 is directly stamped from a new stainless steel plate, which ensures that the material can withstand the high temperature environment of 950 ° C ~ 1050 ° C from the material. adaptability. Finally, it is welded by argon arc welding.

[0040] The joint between the rocker arm 2 and the bypass valve 3 is round and loose. Therefore, the bypass valve cannot rotate freely. Through this reasonable anti-rotation connection structure design, it is ensured that the bypass valve 3 cannot freely rotate on the rocker arm 2, and wear is reduced.

[0041] The bonding...

Embodiment 2

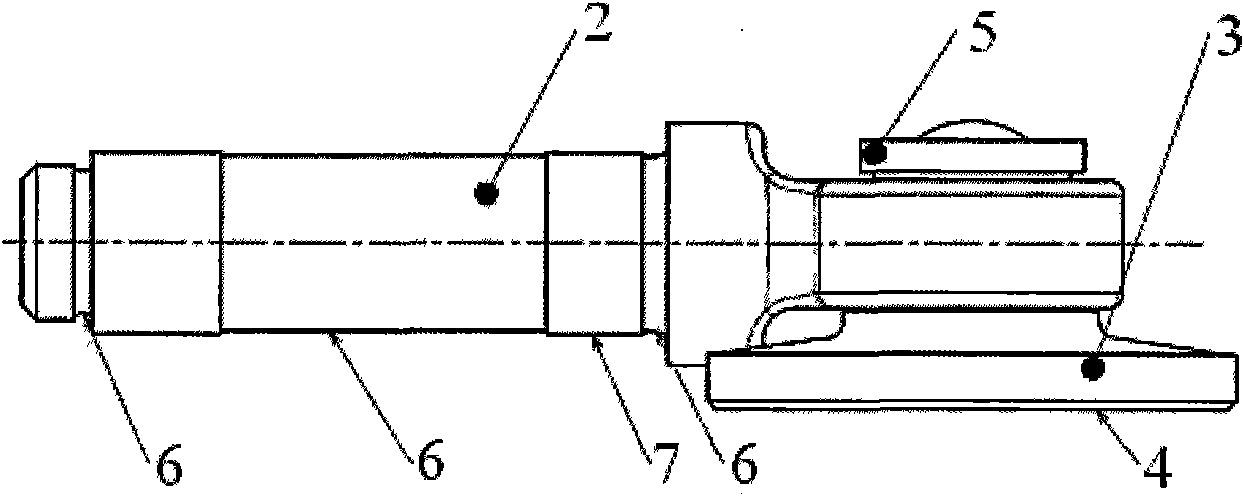

[0043] Such as Image 6 , Figure 7 with Figure 8 As shown, the cross section of the valve connection boss 9 of the present invention is circular, the rocker arm connection hole 10 is a round hole, and matches with the valve connection boss 9, and the bypass valve 3 and On one side connected with the valve connection boss 9, an anti-rotation pin 8 is provided, and the side surfaces of the anti-rotation pin 8 and the side surfaces of the rocker arm 2 are attached to each other.

[0044] Such as Image 6 As shown, the rocker arm 2 and the bypass valve 3 are made of new high-temperature-resistant stainless steel investment casting precision casting, and the gasket 5 is directly stamped from a new stainless steel plate, which ensures that the material can withstand the high temperature environment of 950 ° C ~ 1050 ° C from the material. adaptability. Finally, it is welded by argon arc welding.

[0045] An anti-rotation pin 8 is cast on the bypass valve 3 . The joint betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com