Wind-power generating variable-propeller speed reducer

A technology of reduction gear and motor flange, which is applied to wind power generator components, wind power generation, wind power engines, etc., and can solve problems such as poor speed ratio adjustment accuracy of pitch reduction gear, increased rotor cover volume, and increased installation space. , to achieve the effects of high speed ratio adjustment accuracy, reduced volume and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

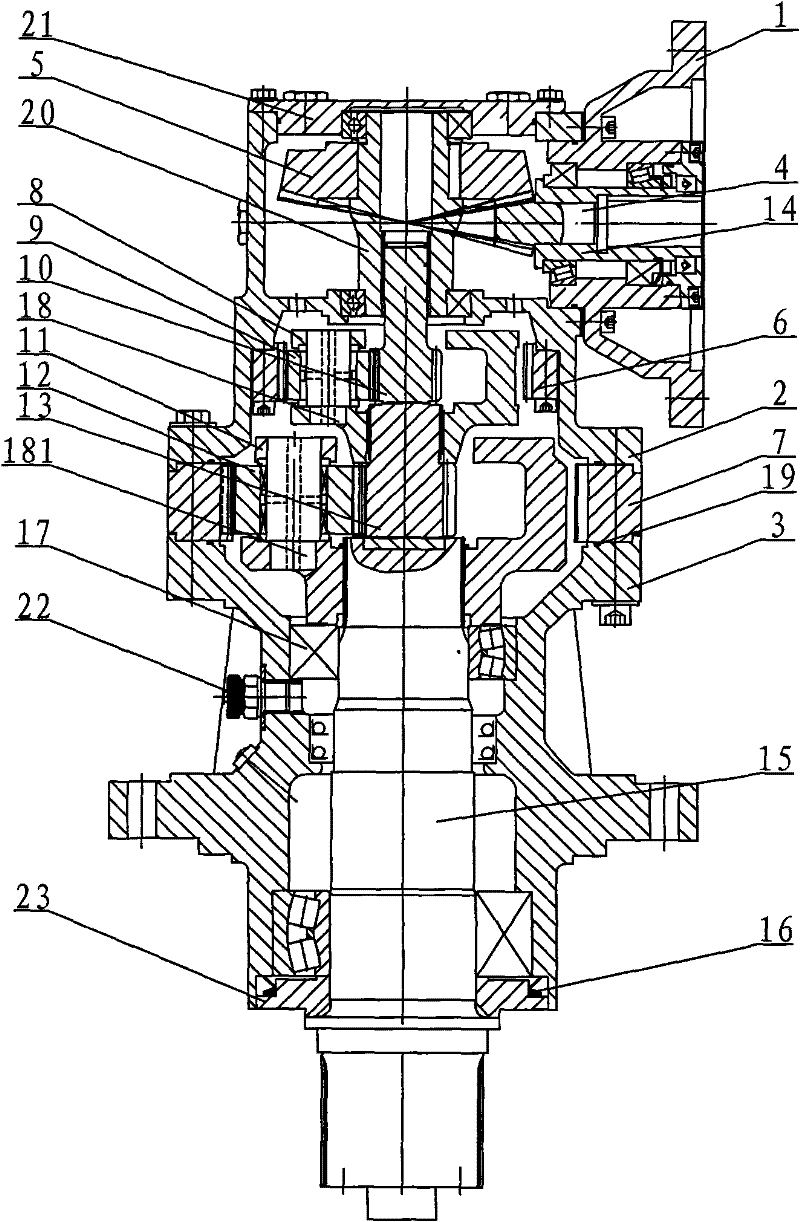

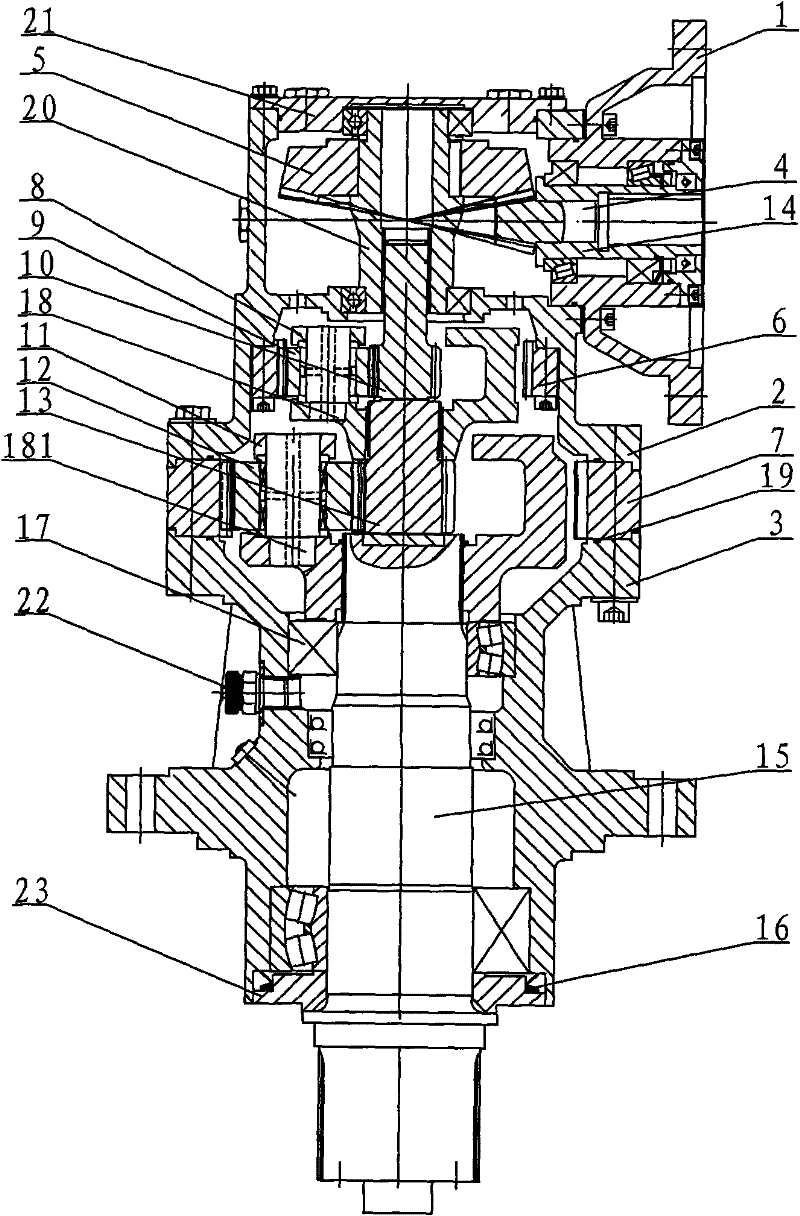

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] figure 1 As shown, the pitch reduction device for wind power generation mainly includes: motor flange 1, front casing 2, support body 3, bevel gear shaft 4, bevel gear 5, output shaft 15, first-stage internal ring gear 6, second-stage Ring gear 7. The first-stage internal ring gear 6 is fixed in the front casing 2 by bolts, and the second-stage internal ring gear 7 is fixedly connected between the front casing 2 and the support body 3 by bolts; the motor flange 1 is vertically connected to the front casing by bolts. On one side of the casing 2, the motor flange 1 is provided with an input shaft connecting sleeve 14, which is in interference connection with the bevel gear shaft 4; One end of the bevel gear connecting sleeve 20 is connected, the other end of the bevel gear connecting sleeve 20 is connected in the front casing 2 through the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com