Liquid lens element and manufacturing method thereof

A liquid lens and manufacturing method technology, applied in the directions of lenses, optical elements, optics, etc., can solve the problems of increased material cost, liquid leakage, difficult production, etc., and achieve the effects of low material cost, avoiding air bubbles, and preventing damage to the upper structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical content of the present invention will be clearly explained in the following preferred embodiments with reference to the accompanying drawings:

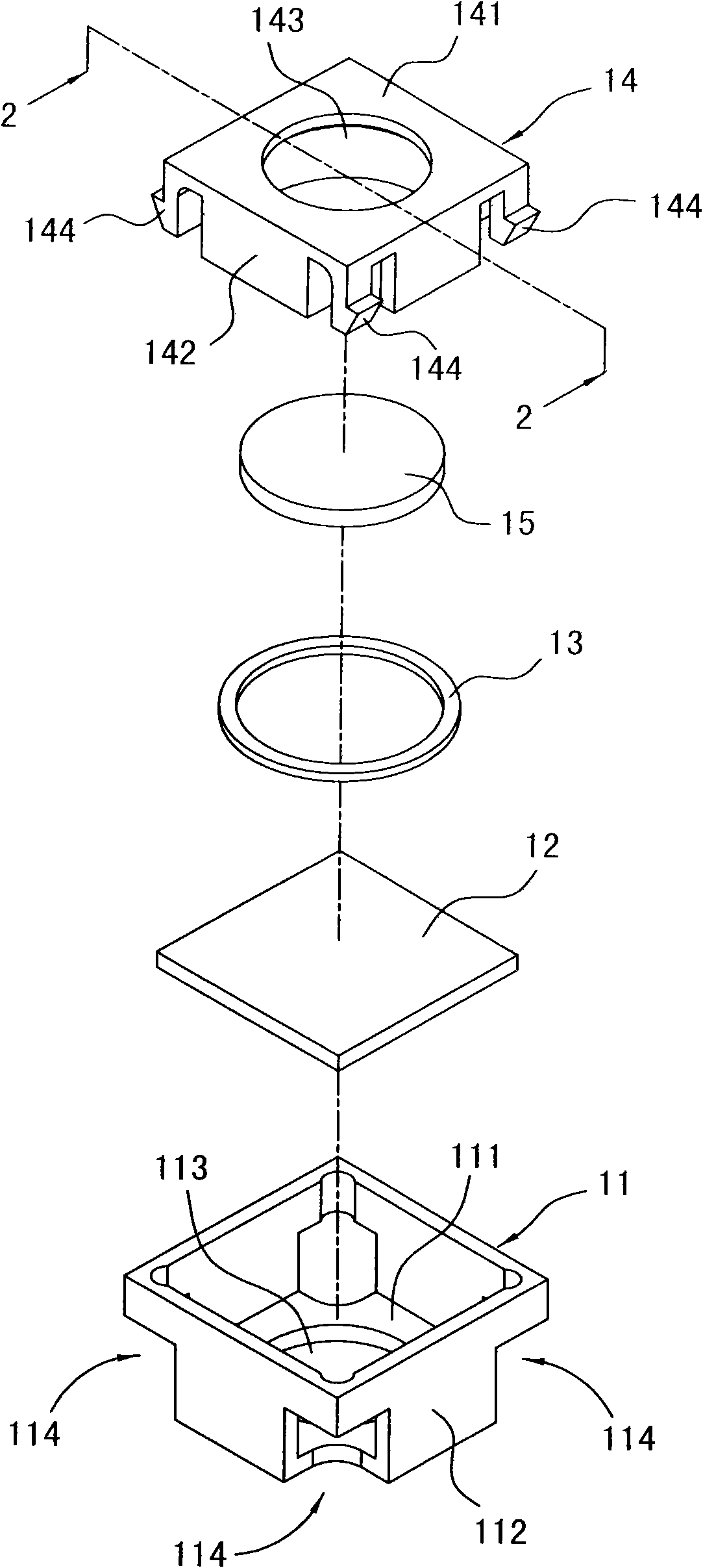

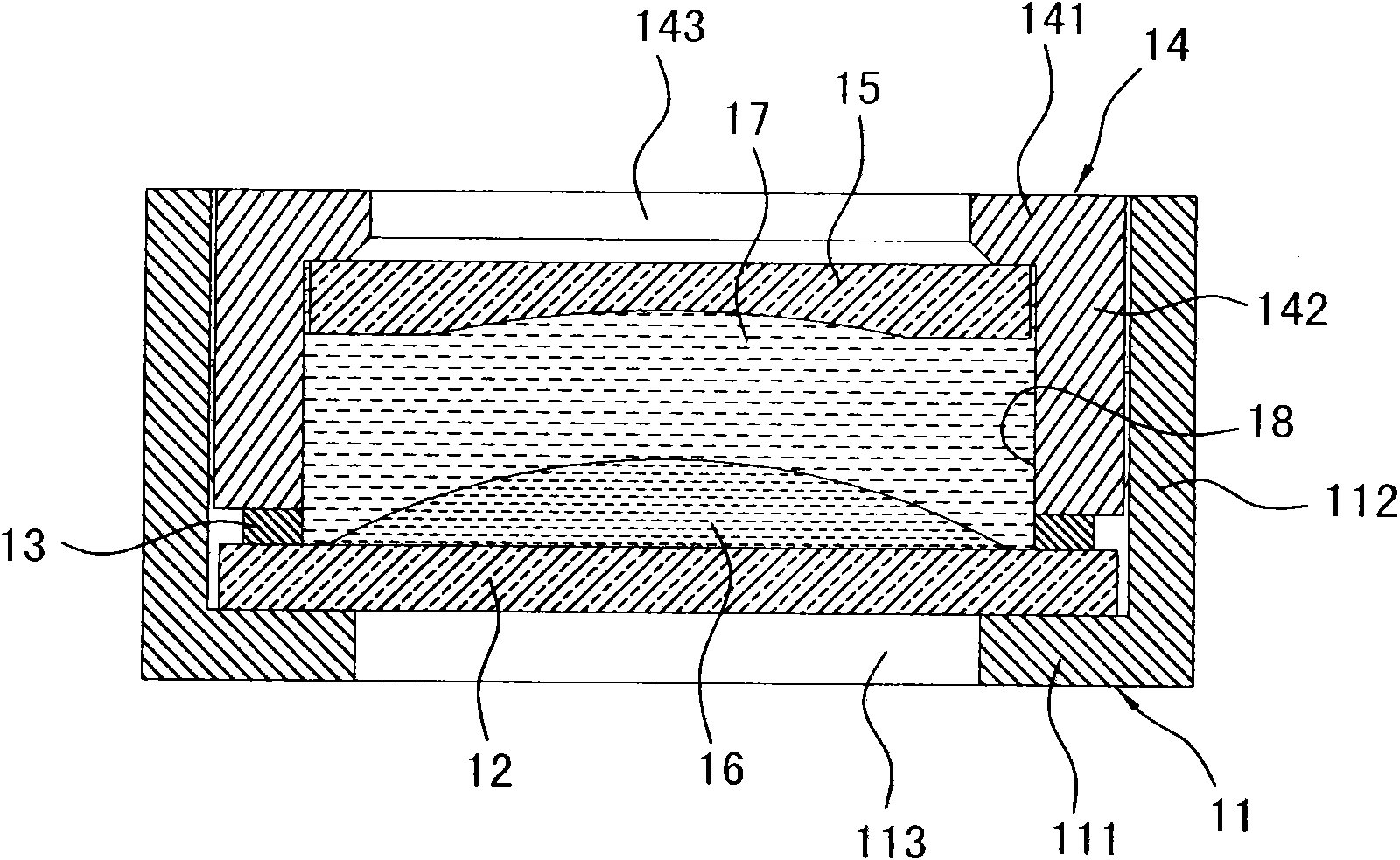

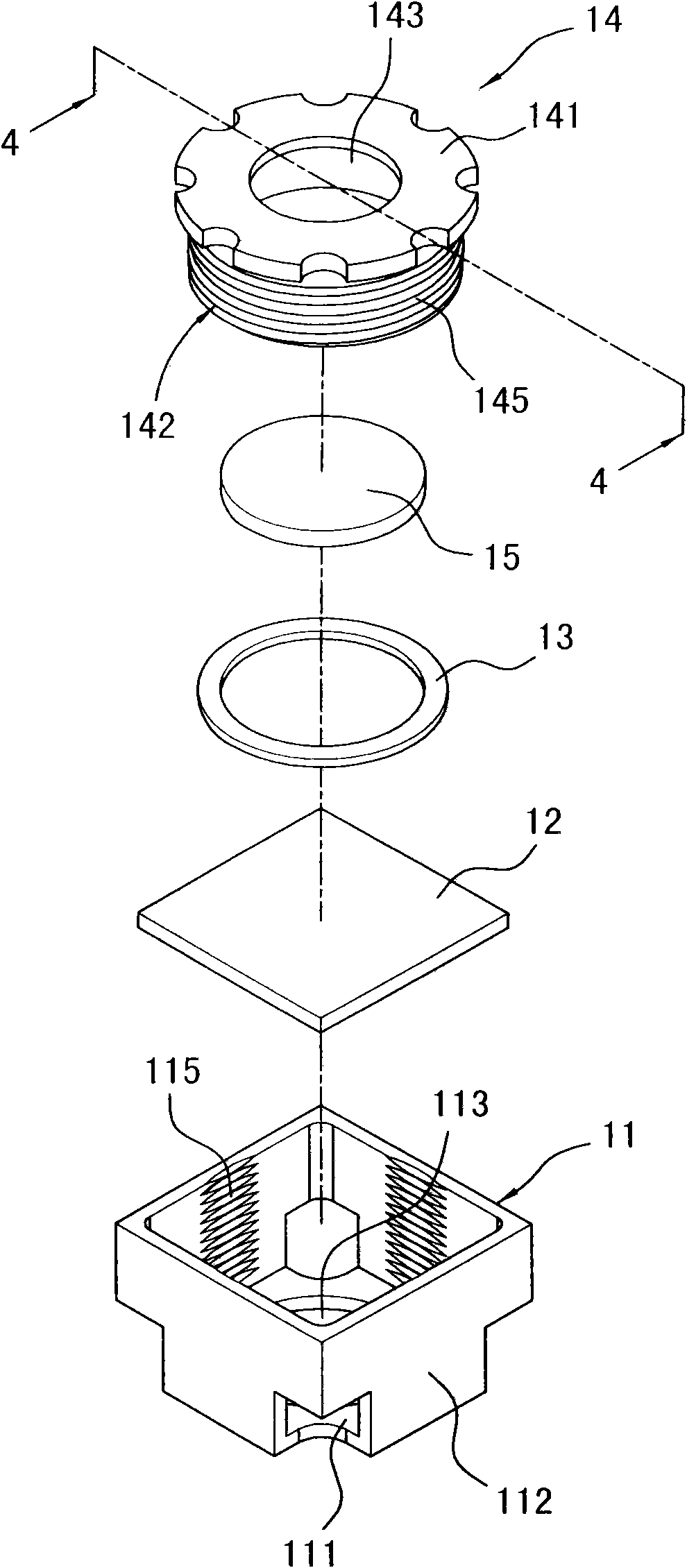

[0045] figure 1 and figure 2 As shown, it is the first preferred embodiment of the variable focus liquid lens element of the present invention, and the liquid lens element mainly includes a lower lens base 11, a light-transmitting electrode sheet 12, a rubber ring 13, an upper lens barrel 14, a transparent Light sheet 15, a first liquid layer 17 (see figure 2 ), and a second liquid layer 16 (see figure 2 ).

[0046] The lower mirror base 11 has a bottom wall 111 and a first surrounding wall 112 extending upward from the bottom wall 111 , and the bottom wall 111 has a lower mirror hole 113 . The lower mirror base 11 is made of plastic materials such as liquid crystal polymer (LCP), polycarbonate (polycarbonate; PC) and glass fiber mixture, polyvinyl toluene PVT (polyvinyl toluene PVT), or polyamide (polyamid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com