Preparation method of high-viscosity modified asphalt waterproof coiled material

A technology for modifying asphalt and waterproofing membranes, which is used in asphalt coatings, chemical instruments and methods, flat products, etc. to improve high temperature stability, enhance adsorption capacity, and enhance water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of high-viscosity modified bitumen waterproof membrane comprises the following steps:

[0033] Step S1, preparation of tire base fabric: heating polyester to 280°C to make it completely melted, adding glass fiber (the length of glass fiber is 0.6-1.0mm) and stirring at 3000r / min for 60min with a high-speed shearing machine, wherein, The mass ratio of polyester and glass fiber is 3:2, and then pour it on a glass plate to spread the thickness of 0.5-0.6mm, and dry it at room temperature for 3-4 hours to obtain the base fabric;

[0034] The obtained base cloth is a polyester fiberglass cloth with high strength. When used as the base of the coil, it forms an integrated structure with the asphalt and acts as the skeleton of the coil, which can prevent structural damage and improve the deformation resistance of the coil. and high temperature resistance;

[0035] Step S2, pretreatment of the tire base cloth: put the tire base cloth into an electric blas...

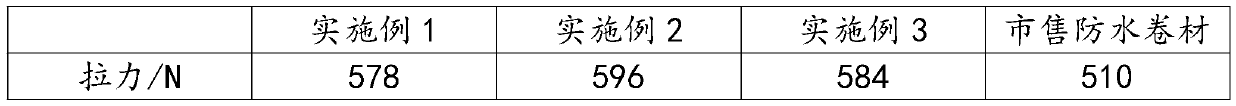

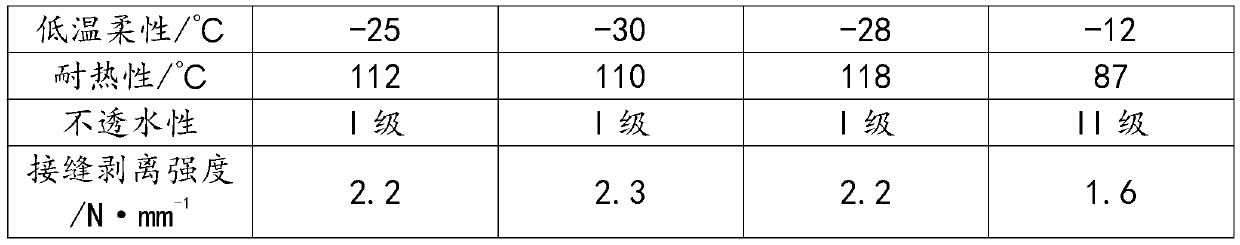

Embodiment 1

[0053] The preparation method of high-viscosity modified bitumen waterproof membrane comprises the following steps:

[0054] Step S1, preparation of base fabric: Heat polyester to 280°C to melt it completely, add glass fiber and stir at 3000r / min for 60min with a high-speed shearing machine, wherein the mass ratio of polyester to glass fiber is 3:2, Then pour it on a glass plate and spread it to a thickness of 0.5 mm, and dry it at room temperature for 3 hours to obtain a tire base cloth;

[0055] Step S2, pretreatment of the tire base fabric: put the tire base fabric into an electric blast drying oven at 180°C and dry for 30 minutes;

[0056] Step S3, pre-impregnation: heat the pre-impregnation oil to 180°C, introduce the tire base cloth into the pre-impregnation oil, let the pre-impregnation oil completely flow over the tire base cloth, impregnate for 6 seconds, pull and squeeze out by extrusion rollers, and pull The speed is 5m / s, and the extrusion strength is 0.9MPa;

[...

Embodiment 2

[0067] The preparation method of high-viscosity modified bitumen waterproof membrane comprises the following steps:

[0068] Step S1, preparation of base fabric: Heat polyester to 280°C to melt it completely, add glass fiber and stir at 3000r / min for 60min with a high-speed shearing machine, wherein the mass ratio of polyester to glass fiber is 3:2, Then pour it on a glass plate and spread it to a thickness of 0.55 mm, and dry it at room temperature for 3.5 hours to obtain the tire base cloth;

[0069] Step S2, pretreatment of the tire base cloth: put the tire base cloth into an electric blast drying oven at 180°C and dry for 30-40 minutes, so that the moisture content of the tire body reaches below 0.08%;

[0070] Step S3, pre-impregnation: heat the pre-impregnated oil to 180°C, introduce the tire base cloth into the pre-impregnated oil, let the pre-impregnated oil completely flow over the tire base cloth, impregnate for 7s, pull and squeeze out by extrusion rollers, and pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com