Circuit board introducing device of solder-reflow furnace

A technology of reflow soldering furnace and importing device, which is applied in the direction of auxiliary devices, electrical components assembling printed circuits, welding equipment, etc., which can solve the problems of board climbing, board dropping, board jamming, etc., achieve stable performance and reduce board dropping , Fast and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these embodiments are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions adopted in the examples can be further adjusted according to the conditions of specific manufacturers, and implementation conditions not specified are usually conditions in routine experiments.

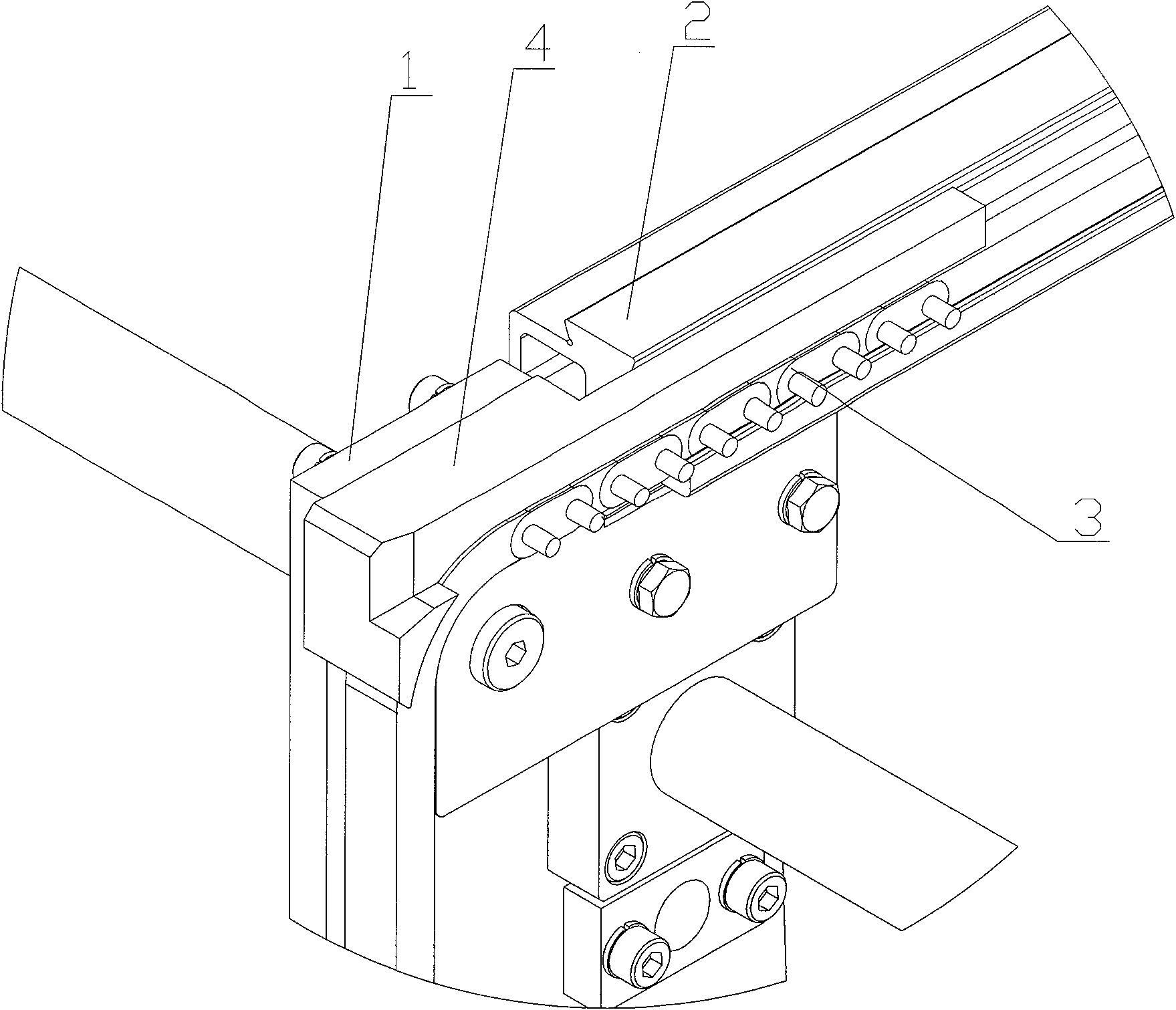

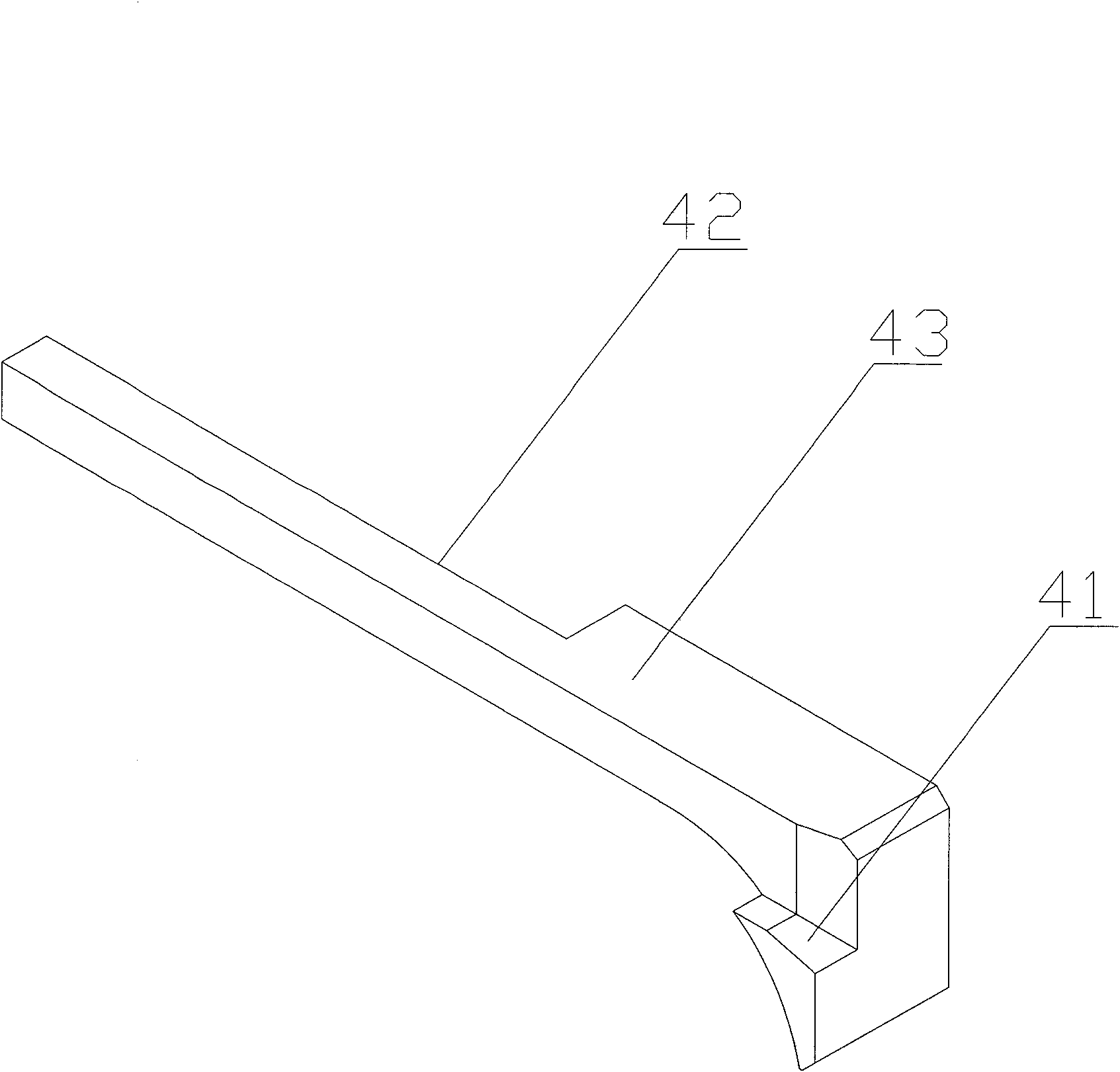

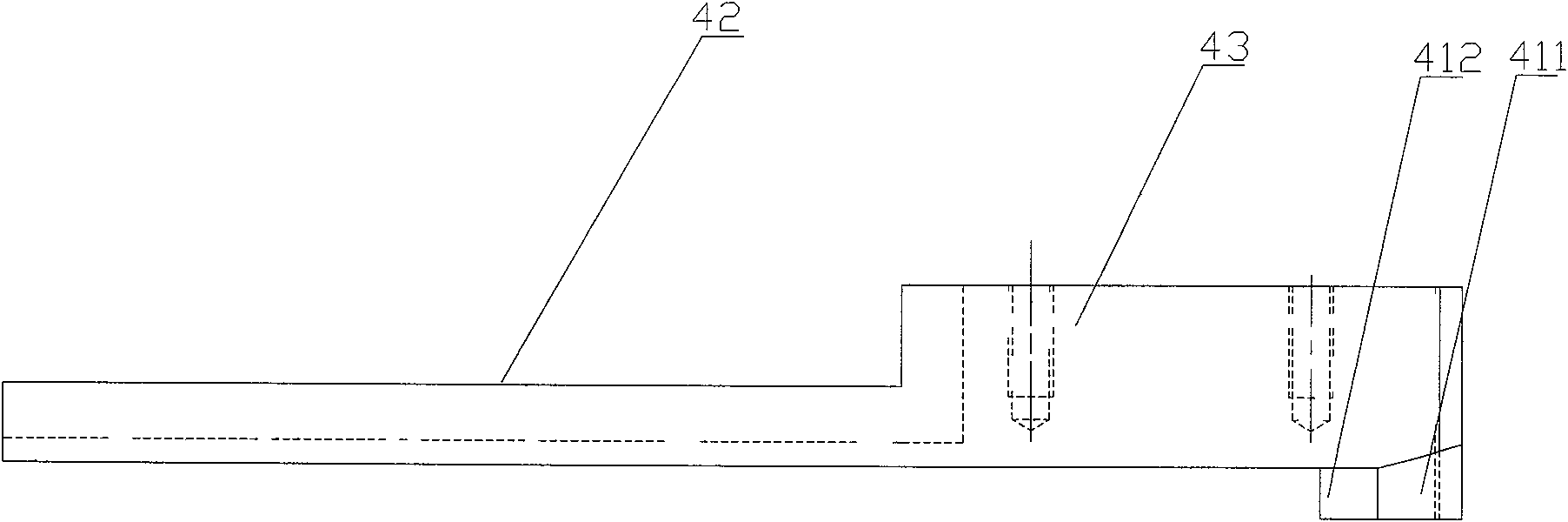

[0031] Implementation example Figure 1~5 , The circuit board introduction device of the reflow soldering furnace, the reflow soldering furnace includes a fixed guide rail 2 fixed on the furnace body bracket 1 at both ends, a conveying chain 3 is arranged in the inner extension of the fixed guide rail 2, and the conveying chain is outside Engaging the sprocket gear driven by the power unit, the front end of the conveyor chain 3 at the entrance of the reflow oven is provided with an introduction block 4, and the intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com