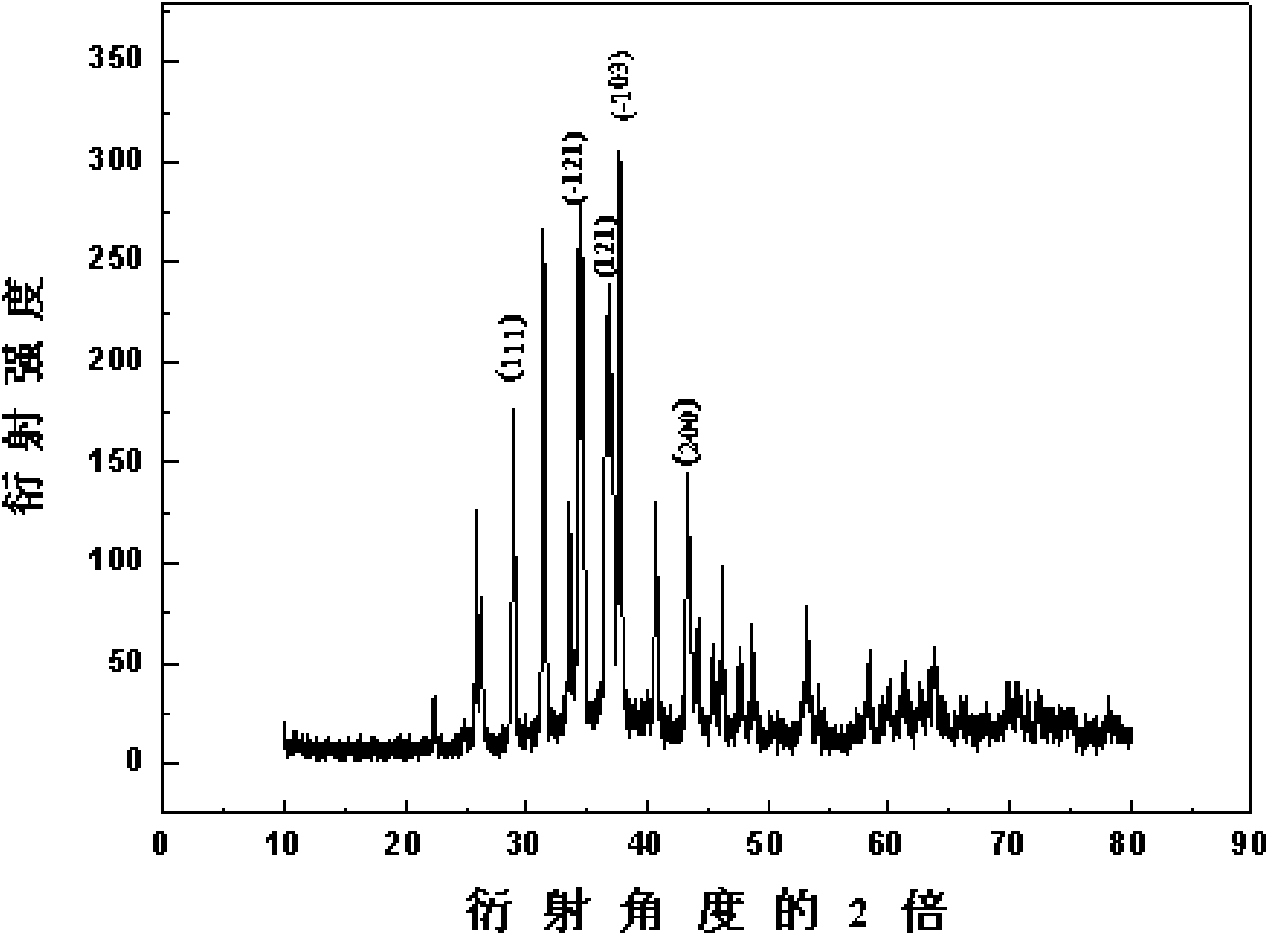

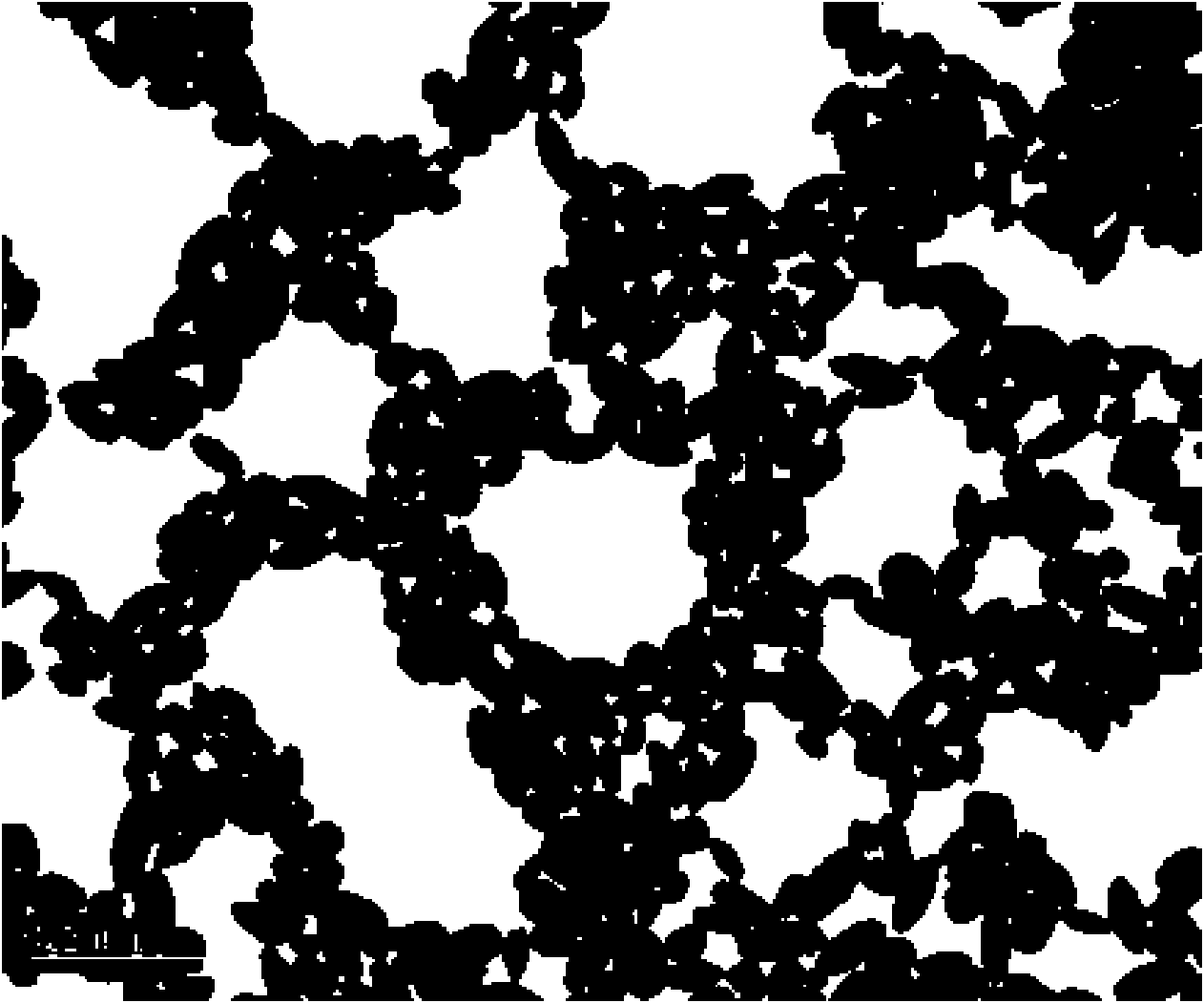

Spindle or rodlike silver sulfide nanometer particles and preparation method thereof

A silver sulfide, rod-shaped technology, applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve the problems of difficult batch production, complex process, high toxicity, etc., and achieve low cost, simple process, and uniform shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) In a 50mL Erlenmeyer flask, dissolve 0.38g of PVP-K30 (molecular weight 25,000-40,000) in 15mL of deionized water, and stir magnetically for 30 minutes to completely dissolve the PVP.

[0033] (2) Add 0.60g Na2S·9H 2 O was dissolved in 10 mL of deionized water to obtain an aqueous sodium sulfide solution with a concentration of 0.250 M.

[0034] (3) Dissolve 0.34g4 silver nitrate in 10mL deionized water to obtain 0.200M silver nitrate aqueous solution. Then, 1 wt % dilute ammonia water was added dropwise under stirring until the white turbidity just disappeared.

[0035] (4) Take 0.80 mL of the sodium sulfide aqueous solution in (2) and add it into the PVP aqueous solution prepared in (1), and stir magnetically for 30 minutes at room temperature to make it evenly mixed. Add 0.20 mL of the ammonia solution of silver nitrate prepared in (3) dropwise to the PVP aqueous solution of sodium sulfide, and stir at room temperature for 1 hour to obtain a uniformly mixed rea...

Embodiment 2

[0038] (1) In a 50mL Erlenmeyer flask, dissolve 0.35g of PVP-K30 (molecular weight 25,000-40,000) in 10mL of deionized water, and stir magnetically for 30 minutes to completely dissolve the PVP.

[0039] (2) Add 0.06gNa 2 S·9H 2 O was dissolved in 10 mL of deionized water to obtain an aqueous sodium sulfide solution with a concentration of 0.025 M.

[0040] (3) 0.34 g of silver nitrate was dissolved in 10 mL of deionized water to obtain a 0.200 M silver nitrate aqueous solution. Then, 1 wt % dilute ammonia water was added dropwise under stirring until the white turbidity just disappeared.

[0041] (4) Add 4.00 mL of the sodium sulfide aqueous solution in (2) to the PVP aqueous solution prepared in (1), and stir magnetically for 30 minutes at room temperature to mix the solution completely. Add 0.10 mL of the ammonia solution of silver nitrate prepared in (3) dropwise to the PVP aqueous solution of sodium sulfide, and stir at room temperature for 1 hour to obtain a uniformly...

Embodiment 3

[0044] (1) In a 50mL Erlenmeyer flask, dissolve 0.10g of PVP-K15 (molecular weight: 10,000) in 20mL of deionized water, and stir magnetically for 30 minutes to completely dissolve the PVP.

[0045] (2) Add 0.48gNa 2 S·9H 2 O was dissolved in 10 mL of deionized water to obtain a sodium sulfide aqueous solution with a concentration of 0.200 M.

[0046](3) 0.34 g of silver nitrate was dissolved in 10 mL of deionized water to obtain a 0.200 M silver nitrate aqueous solution. Then, 1 wt % dilute ammonia water was added dropwise under stirring until the white turbidity just disappeared.

[0047] (4) Add 1.40 mL of the sodium sulfide aqueous solution in (2) to the PVP aqueous solution prepared in (1), and stir magnetically for 30 minutes at room temperature to mix the solution completely. Add 0.28 mL of the ammonia solution of silver nitrate prepared in (3) dropwise to the PVP aqueous solution of sodium sulfide, and stir at room temperature for 1 hour to obtain a uniformly mixed r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com