Full computer control jacquard warp knitter

A computer-controlled, jacquard warp technology, used in flat warp knitting machines, warp knitting, textiles and papermaking, etc., can solve the problems of narrow bar space, slow swing speed, inconvenient repair, etc., and reduce the number of comb positions. The effect of improving space, productivity, and reducing the weight of the bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

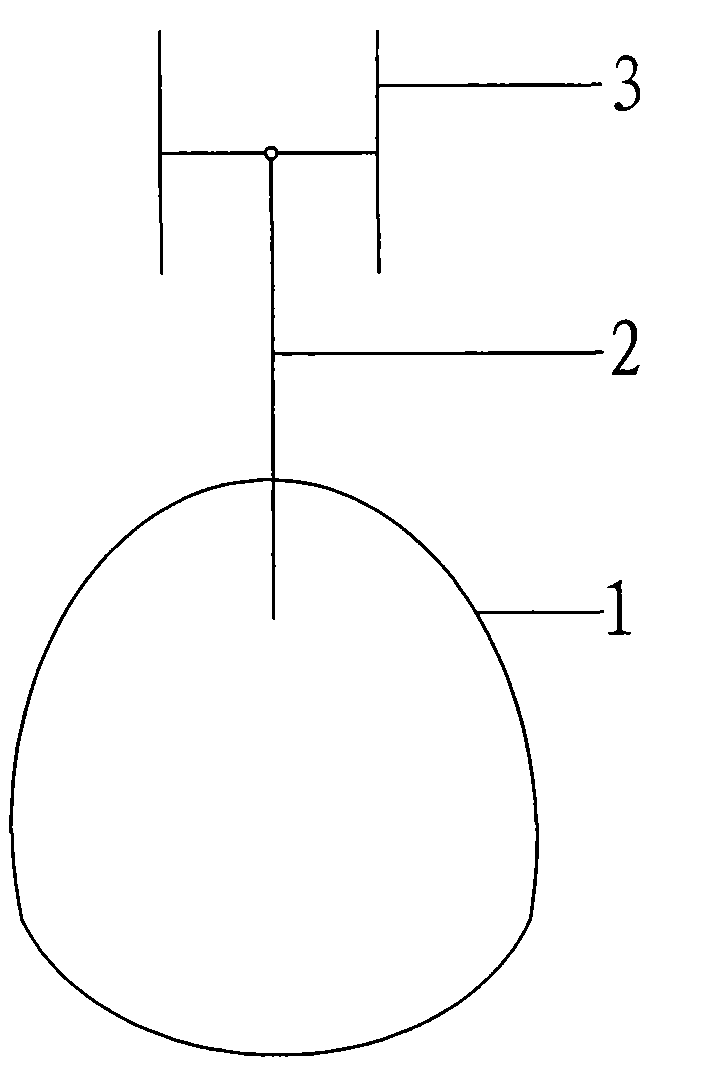

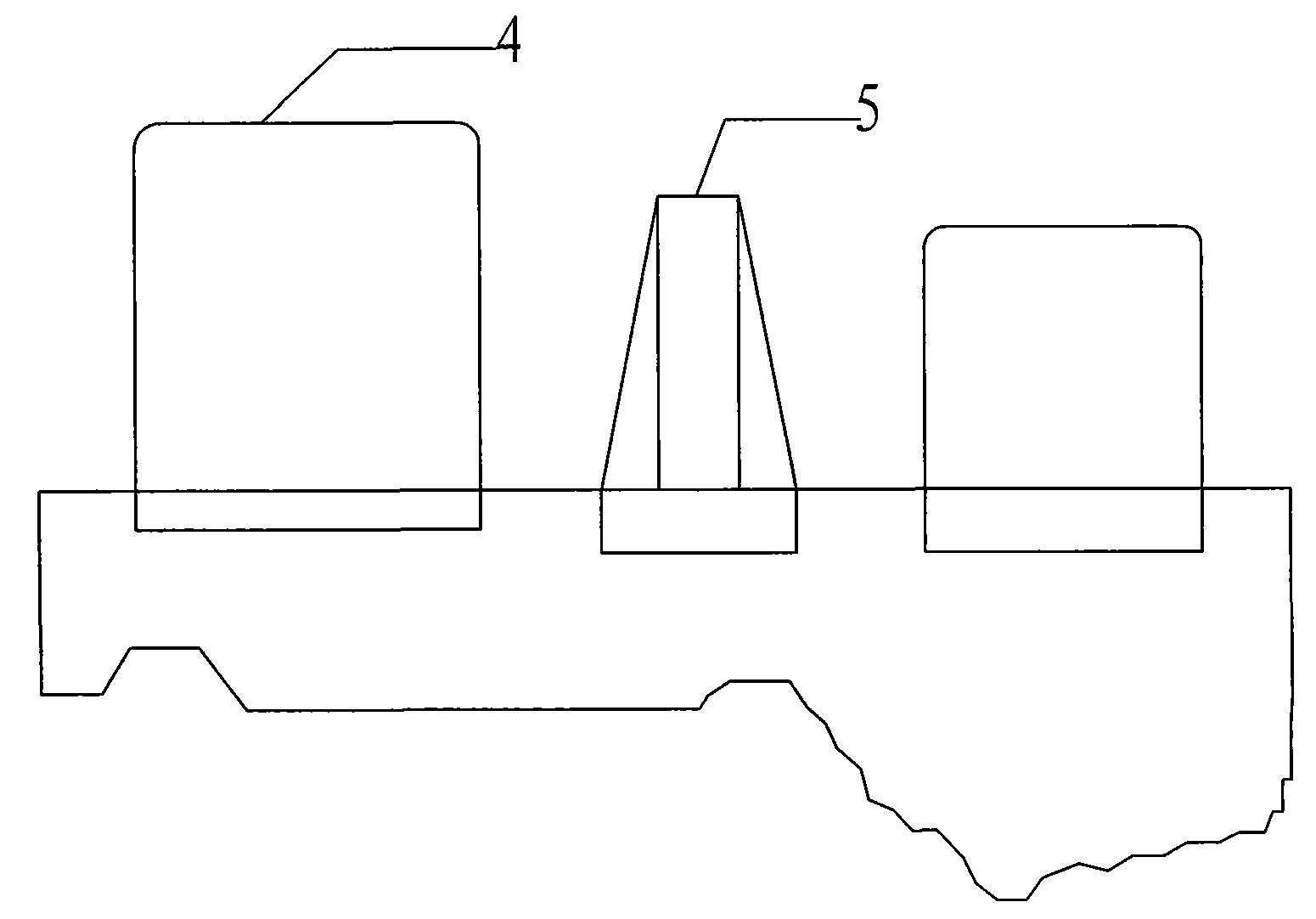

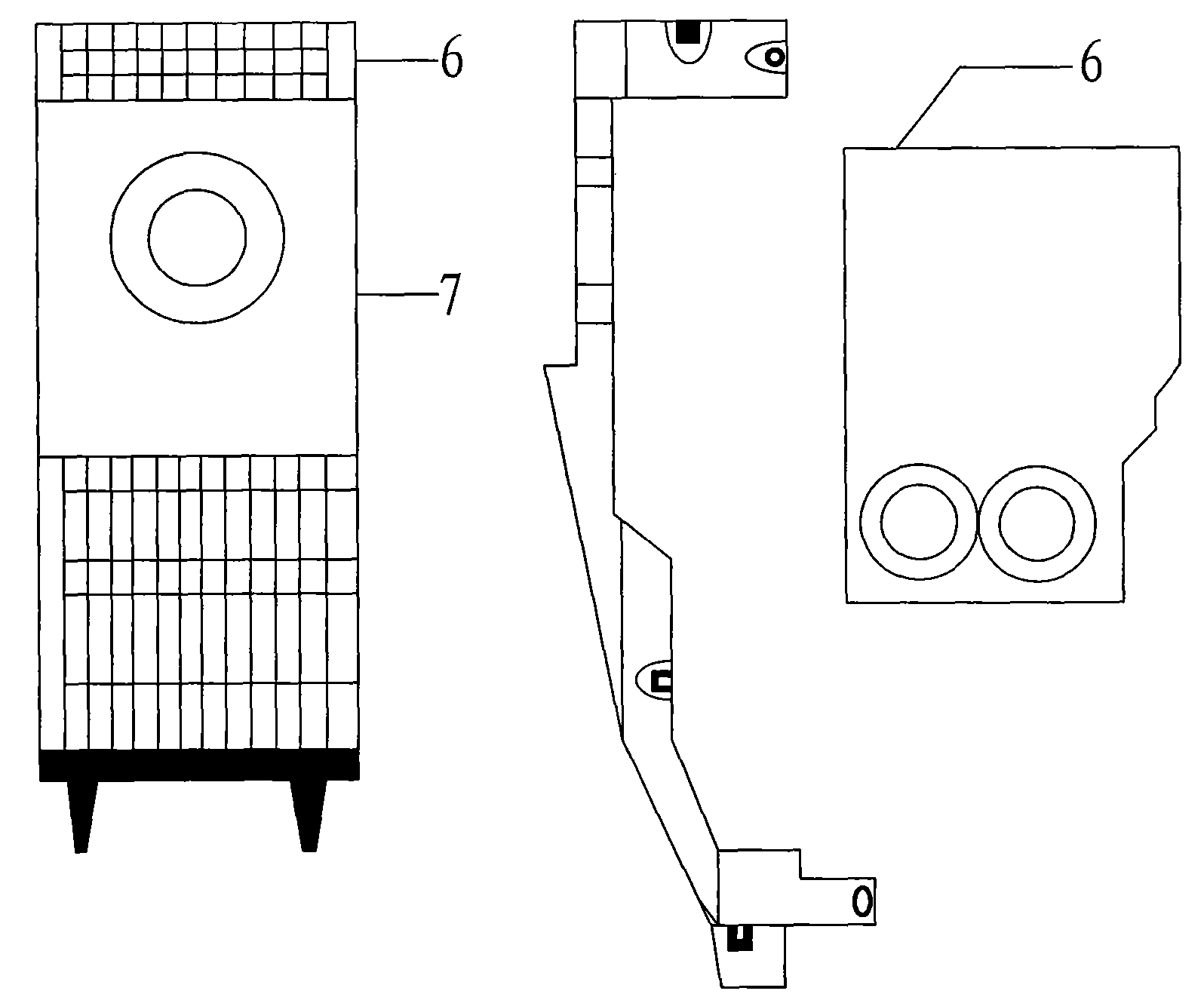

[0023] like Figures 1 to 5 As shown, a fully computer-controlled jacquard warp knitting machine consists of an eccentric cam body 1, a transmission rod 2, a guide groove 3, a main beam 4, a jacquard beam 5, a jacquard comb 6, a jacquard needle box 7, Rolling ejector rod 8, steel comb 9, servo motor 10, shaft head 11, bearing track 12, and yarn guide bar are composed of piezoelectric ceramic needle pieces, and the feature is that the machine also has It includes a computer control system, and the above-mentioned parts are coordinated by the computer control system. The computer control system controls each piece of piezoelectric ceramic needle piece on the yarn guide bar by outputting electronic pulses, and the pulse signal is either left or right. Move to complete intricate jacquard weaves.

[0024] like figure 2 As shown, one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com