Method for repairing and processing bearing hole of main bearing cap of diesel engine body of diesel locomotive

A main bearing cap and main bearing technology is applied in the field of maintenance and processing of main bearing holes of the main bearing cap of the diesel engine body of a diesel locomotive, which can solve the problems of high operation technical requirements, long production cycle, high labor intensity, etc. Quality improvement, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

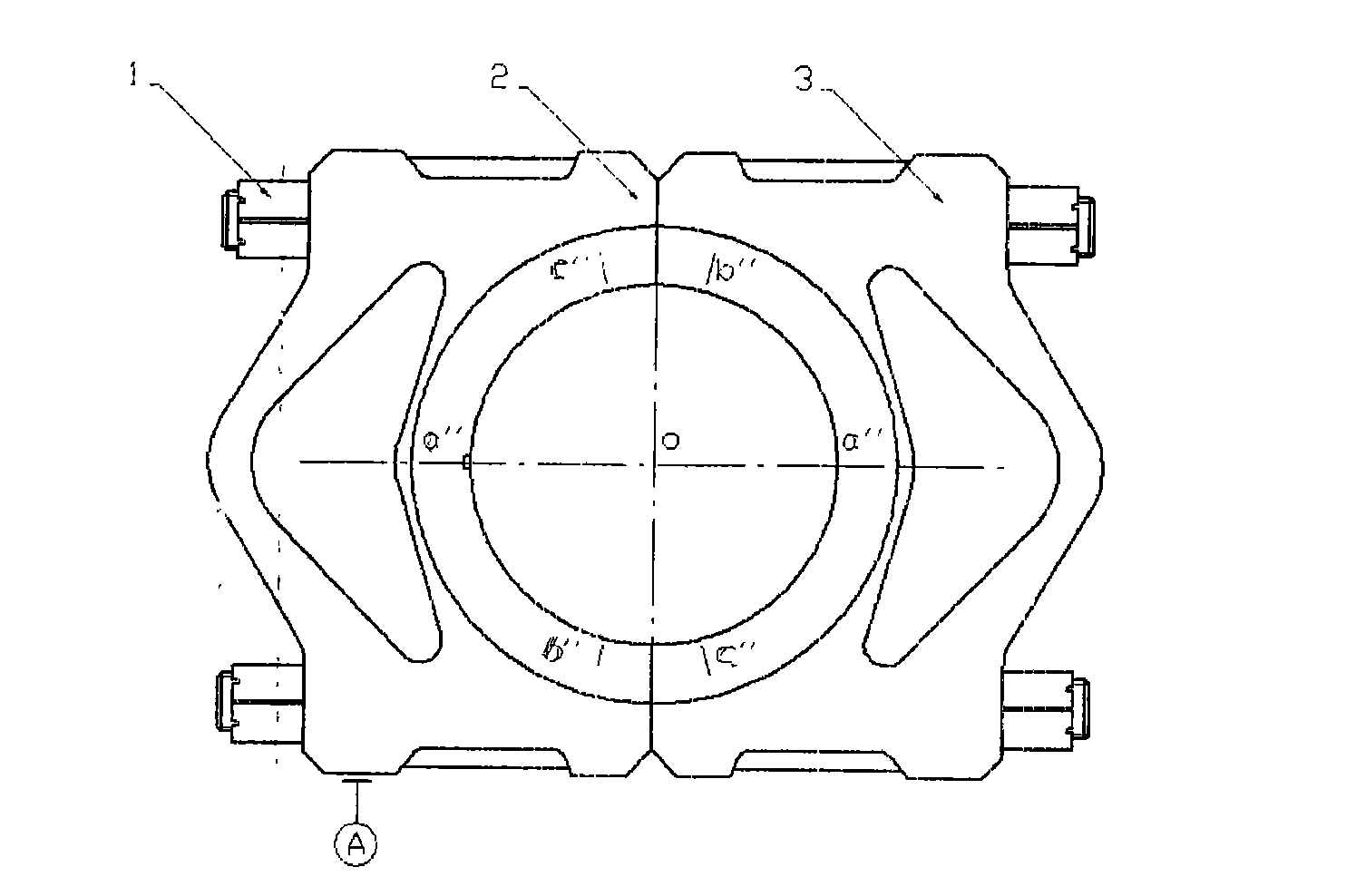

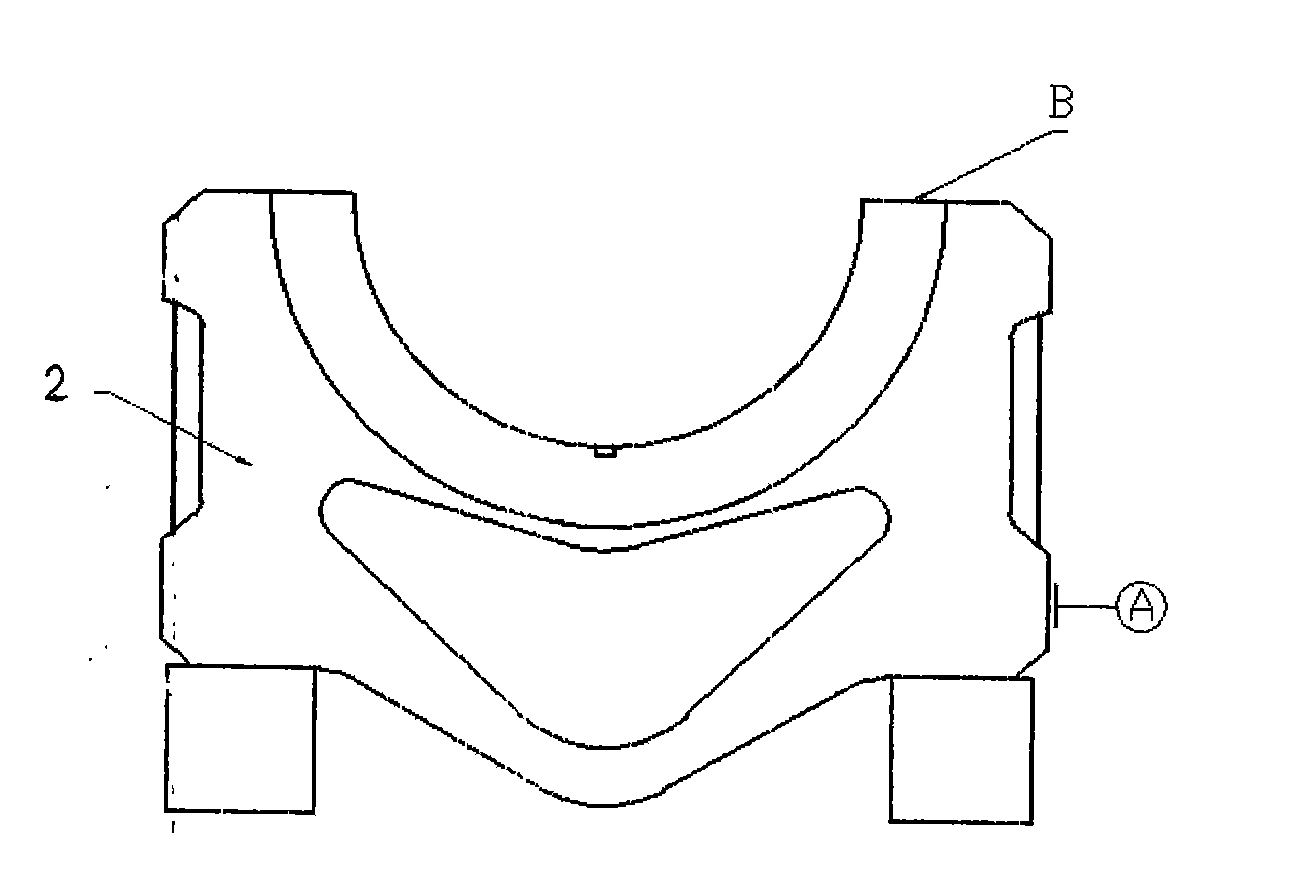

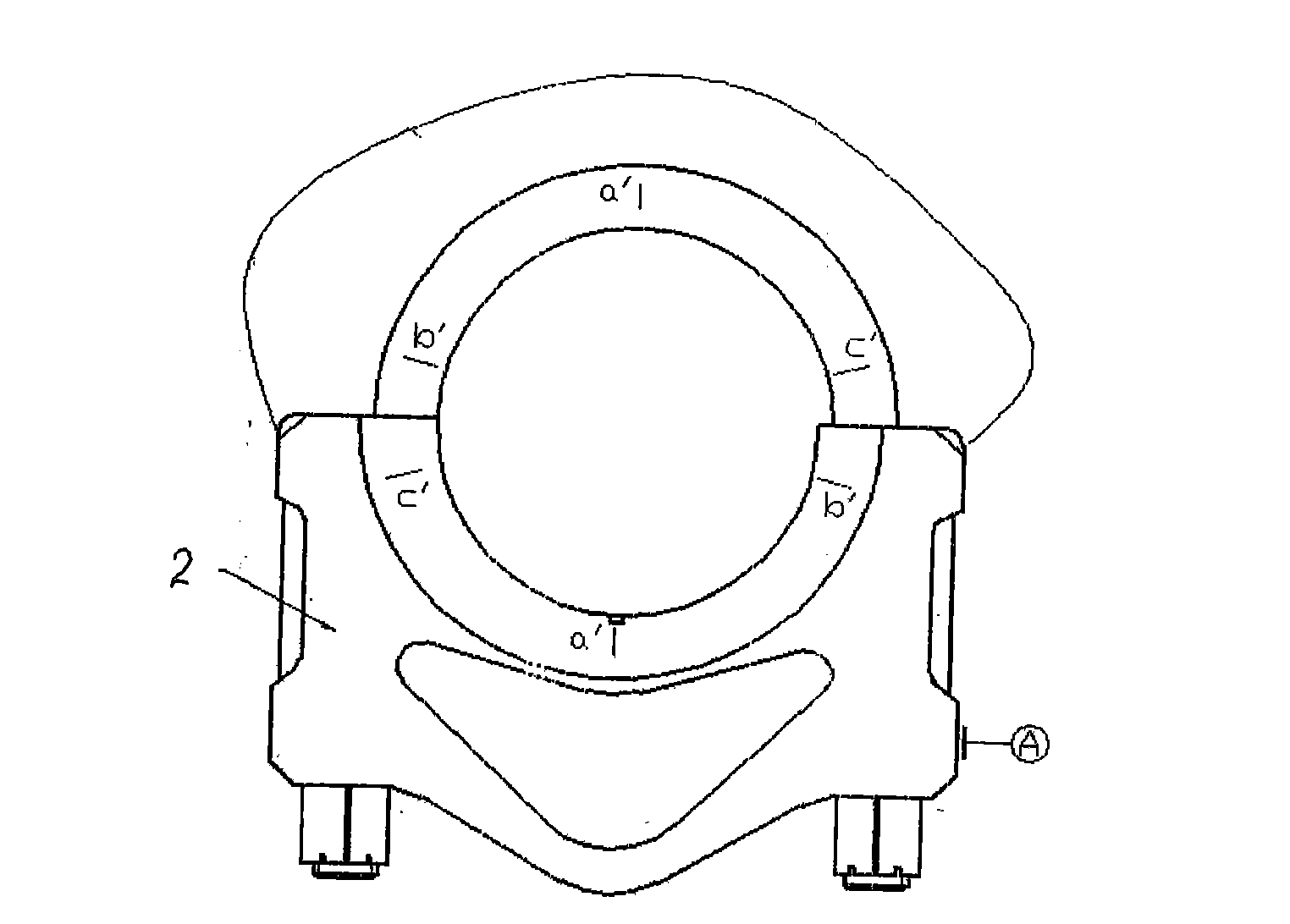

[0032] Method 1: Machining the bearing hole of the original main bearing cap of the diesel engine body:

[0033] like figure 1 As shown, on the level 1 platform, with the same side of the main bearing cap 2 (such as the left side) as the reference, two groups of main bearing caps (2, 3) with defective main bearing holes are placed vertically, facing each other to form a For a complete cylindrical hole, use two fastening bolts (1) to fasten it, use a feeler gauge under the surface A to adjust the diameter b″-b″, c″-c″ in the direction of the minor axis, so that the diameter b″- The difference between b″, c″-c″ is not more than 0.02mm, measure the diameter a″-a″ in the direction of the major axis, record it as A1, remove the fastening bolt (1); measure the two main bearing caps (2, 3) in pairs Relative to the long and short axis diameters of the holes formed after assembly; the main bearing cap 2 (such as figure 2 ) is placed on the vertical milling machine, supported by two ...

Embodiment 2

[0038] Method 2: Replace the original main bearing cap with a semi-finished main bearing cap after processing.

[0039] Assemble the original main bearing cap according to method 1, step a, measure and record the A1 value and then disassemble; pre-install the semi-finished main bearing cap on the machine body, and measure the eccentricity between the bearing hole of the semi-finished main bearing cap and the bearing hole of the frame , assemble the two main bearing caps; according to method 1, step d, install the clamp, align and fix the workpiece on the boring machine, compare the values of B3 and C3, if B3 Figure 4 ), the offset is calculated as follows;

[0040] O-O'=(B3-C3)÷2

[0041] The center of the main shaft of the machine tool and the center of the bearing hole of the semi-finished main bearing cover are offset according to the pre-measured eccentricity, and are processed and assembled according to the method described in claim 2 to restore the coaxiality and apert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com