Method for repairing main gas collecting tube of clean heat recovery coke-oven

A general gas collector and heat recovery technology, which is applied in the direction of preventing/repairing the leakage of bricklaying, etc., can solve the problems of different expansion coefficients of lining bricks, burning damage of the general gas collector, serious economic losses, etc., and achieves low maintenance cost, The effect of slowing down flue gas flow and low economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

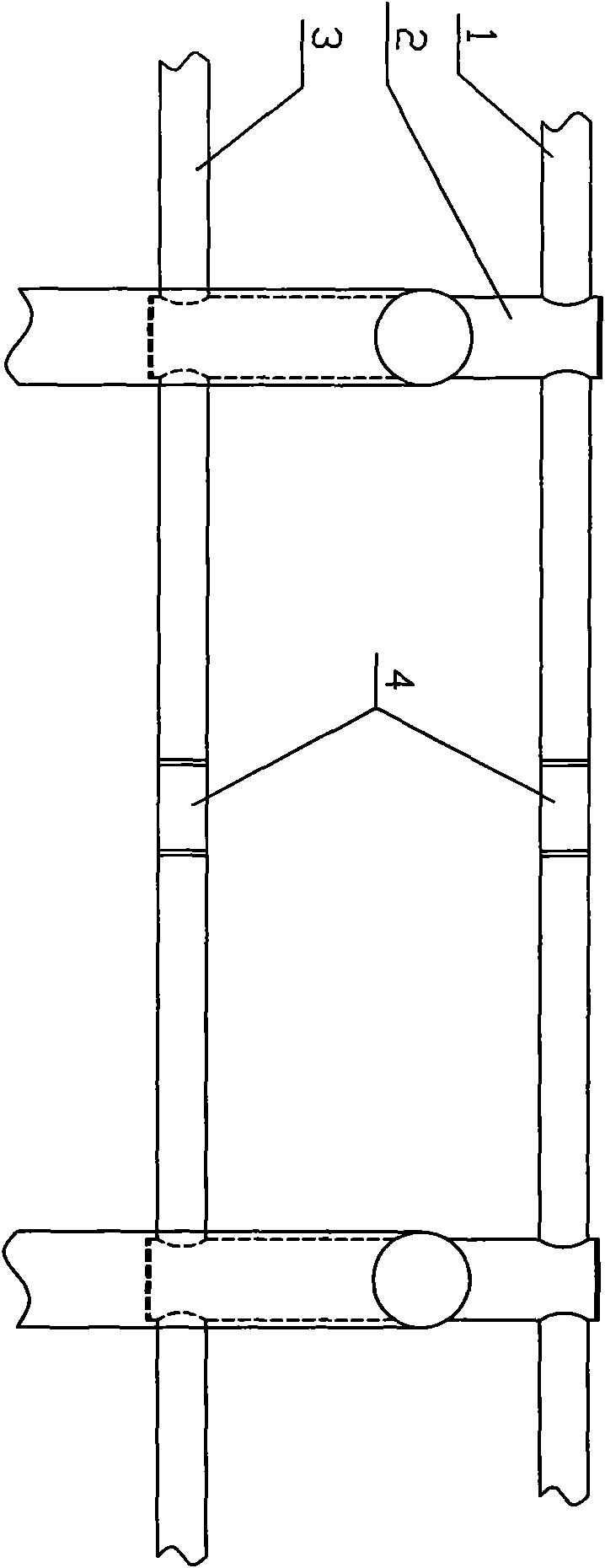

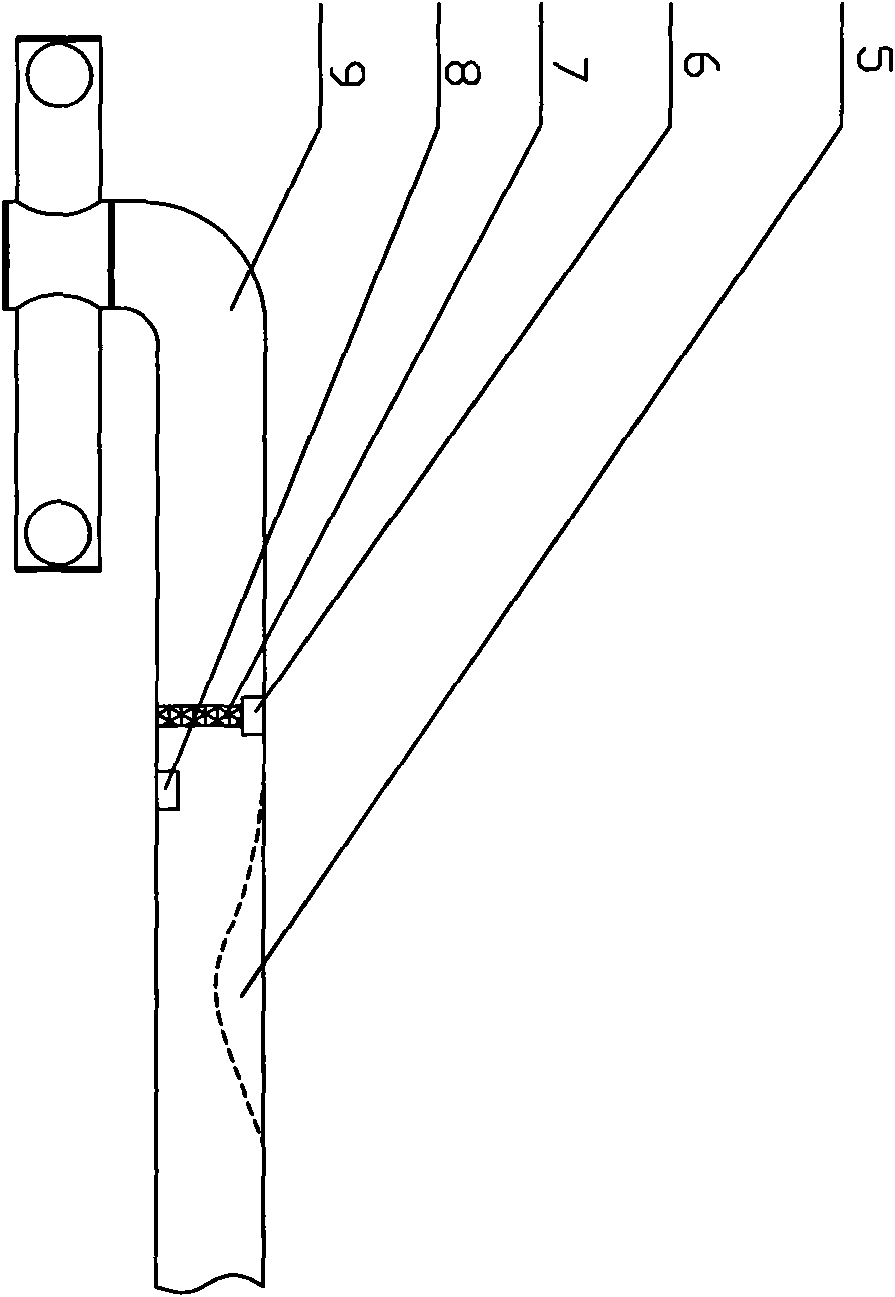

[0015] like figure 1 , figure 2 , image 3 As shown, a maintenance method for the main collecting pipe of a clean heat recovery coke oven includes the following steps:

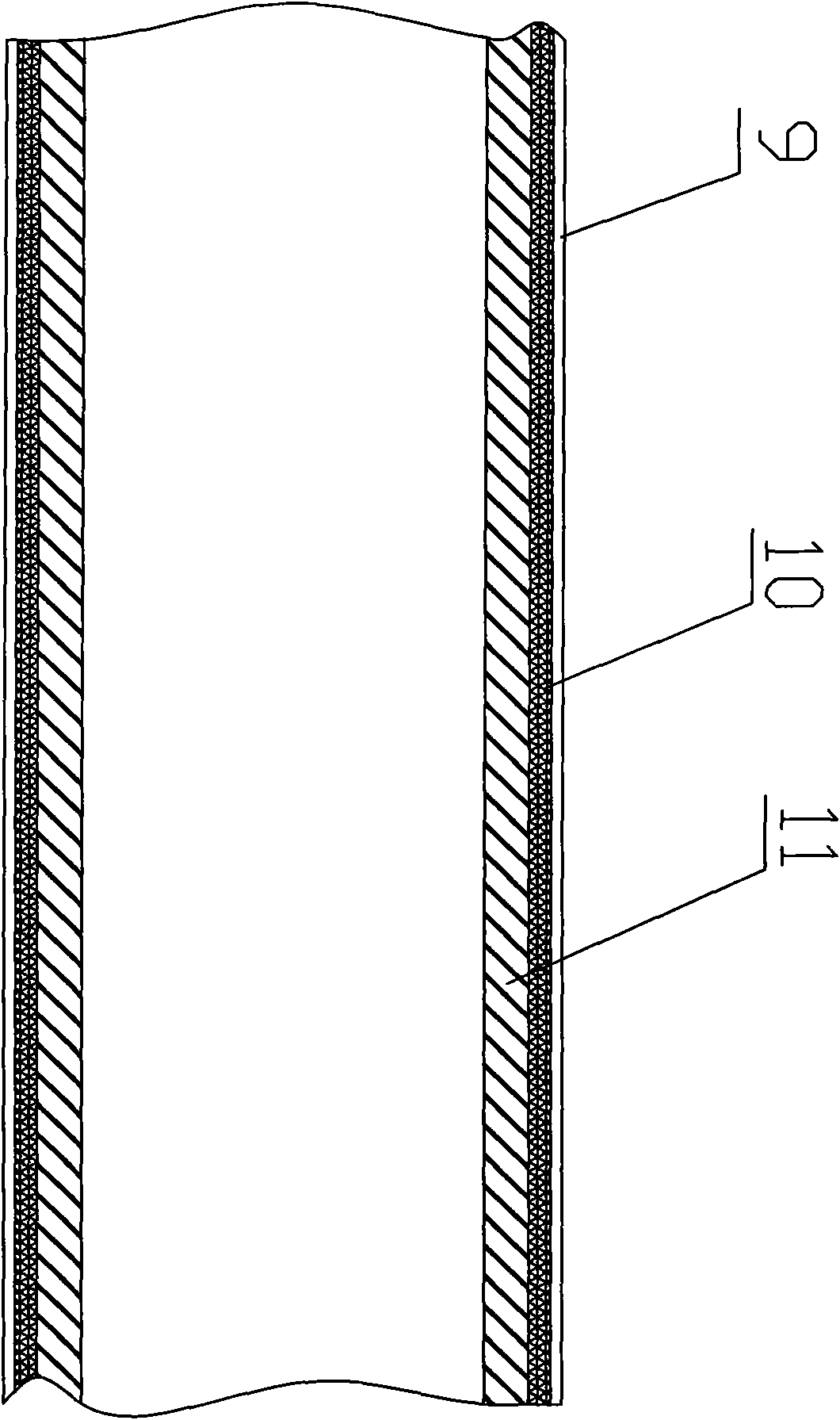

[0016] Use a crane to connect the temporary connecting pipe 4 with the ends of the coke-side air collecting pipe 1 and the machine-side air collecting pipe 3 respectively, and weld and seal it with hoops. The temporary air collecting pipe is Φ1.38×2.15m, and the inner lining is two layers of thermal insulation materials : The middle layer is a heat-insulating silicate board, and the innermost layer is a light-weight insulation brick with a refractory layer.

[0017] Open a sealing wall outlet 6 with an area of 800 × 800mm on the top of the front part of the burned part of the main air collecting pipe 2 about 1 meter away, use waste woven bags to pack high-temperature refractory materials, and use Φ1mm thick thin iron wires to bundle and shape the bundle. Put the woven bag from the outlet of the sealing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com