Method and device for sun screening, heat shielding and cooling of negative pressure adsorption coverings

A covering and negative pressure technology is applied in the field of negative pressure suction and sunscreen screen heat cooling, which can solve the problems of affecting lighting in winter and unsatisfactory heat resistance effect, and achieves good heat cooling effect, low noise and airtightness of the shading screen. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

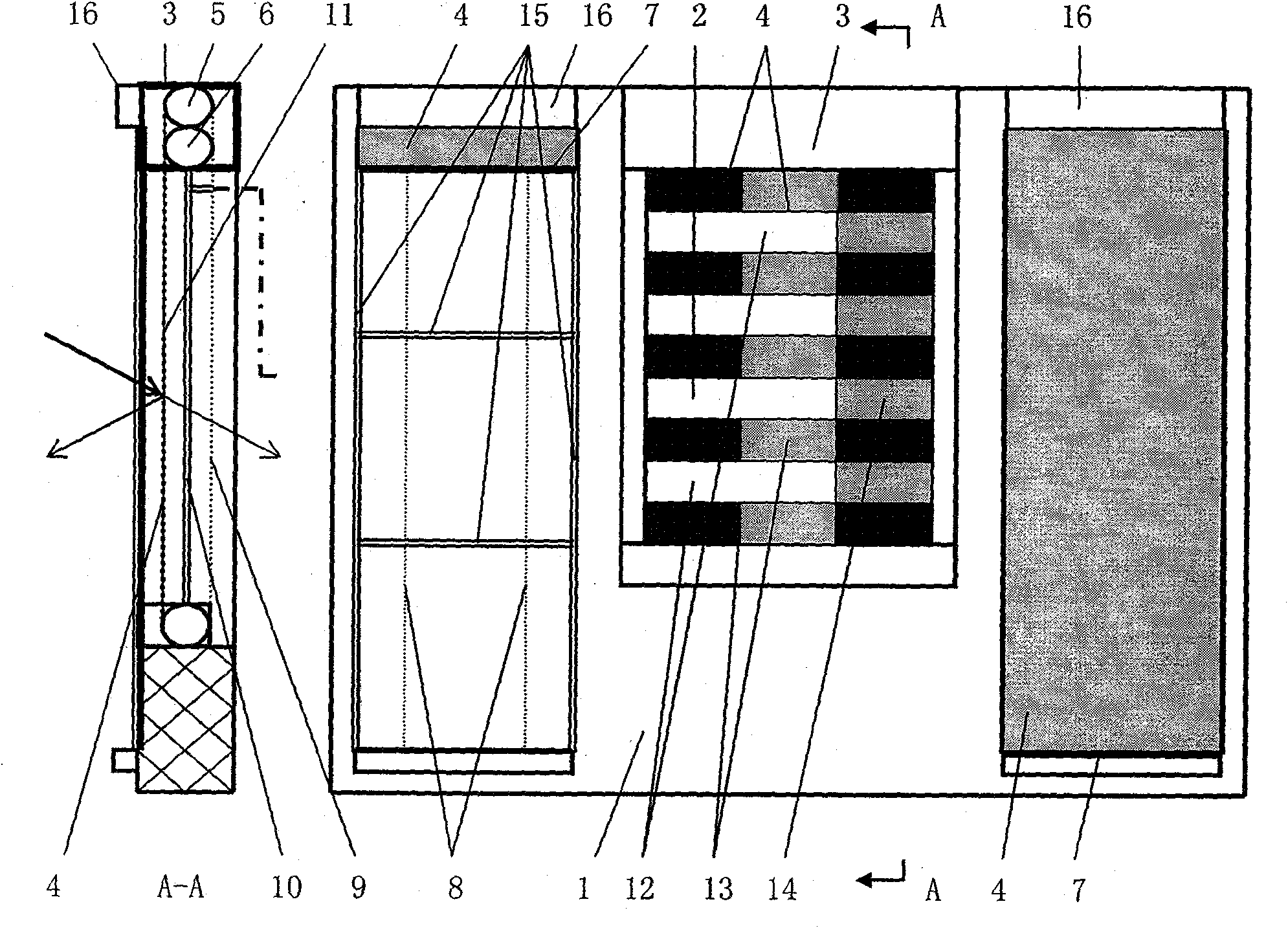

[0013] figure 1 Among them, the window frame 3 of the window 2 of the facade 1 is connected with two winding drums 5 and 6 that are connected to the inner edge of the rollable covering 4 and can be rolled and unfolded; the outer edge of the covering 4 is connected Pull rod 7, and pull rod 7 is connected with drag cable 8. The indoor side of window 2 is provided with two manual chain ropes 9 (only showing one among the figures) that are connected with winding drum 5 and 6 respectively. Pull the manual chain rope 9 to move the cover 4 so that the bonding line on it is bonded to the glass 10, and the cover 5 and the glass 10, that is, the light-receiving surface of the building, form a seamed closed space 11 together. The closed space 11 with seams communicates with the negative pressure source through the exhaust channel shown by the dotted line, so that the cover 4 is sucked onto the glass 10 .

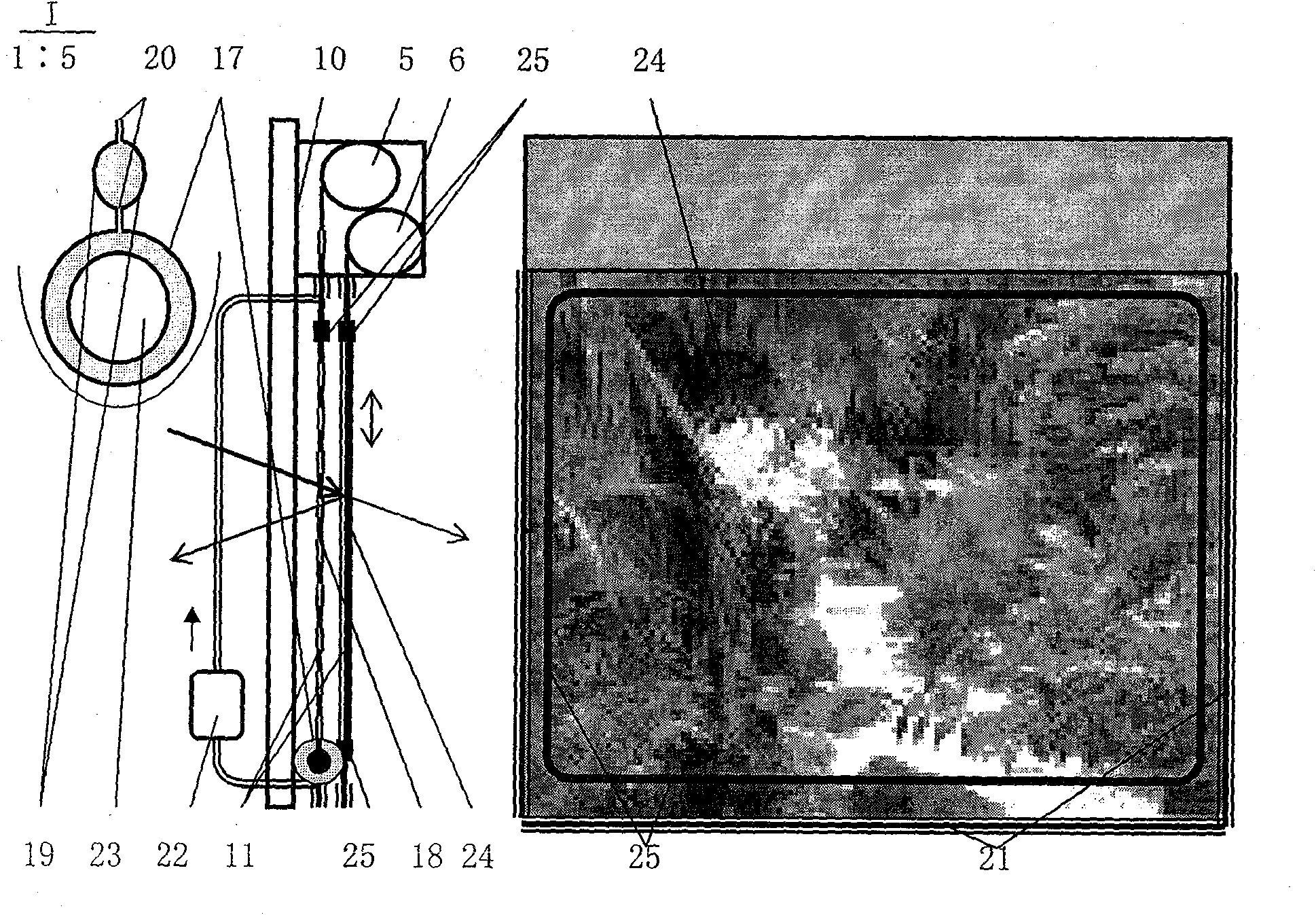

[0014] The double-layer covering 14 can be formed by stacking two rollable zebra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com