Current-limiting soft-starting method of asynchronous motor under wideband power supply

A technology for soft starting of asynchronous motors, applied in motor generators/starters, starters of single multi-phase induction motors, etc., which can solve the requirements of soft starting of cooling fan motors and only allow the power frequency to be within a small range Changes and other issues, to achieve the effects of modular design, significant economic and social benefits, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

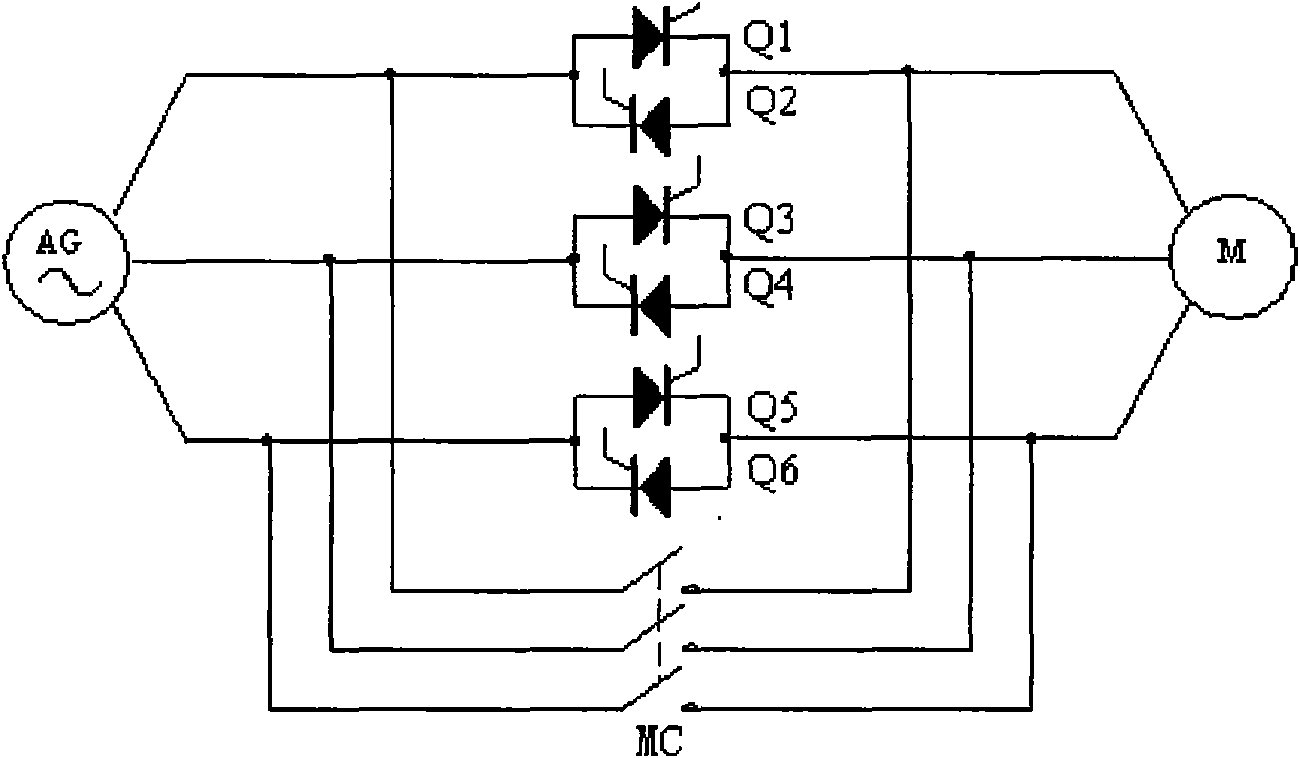

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. See attached image 3, in the three-phase main circuit, a group of anti-parallel thyristors Q1 and Q2, Q3 and Q4, Q5 and Q6 are respectively connected in series, and the bypass contactor MC is connected across the two ends of each group of thyristors.

[0039] See attached Figure 4 , The motor-specific DSPic30f6010A control board used in the control system of the embodiment of the present invention has the characteristics of fast execution speed, strong processing capability, large internal storage space, and rich interfaces. It collects current effective value, motor speed, three-phase voltage Ua, Ub, Uc and other signals, generates each thyristor trigger pulse signal Tr1~Tr6, and drives each thyristor Q1~Q6 through the pulse power amplifier circuit and pulse transformer; generates Do1 signal, through Relay output, control bypass contactor MC.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com