Preparation method for PCB plate with step trough

A PCB board and stepped groove technology, which is applied in the manufacturing of printed circuits, the formation of electrical connection of printed components, electrical components, etc., can solve the problems of patch processing, the inability to pattern the stepped grooves, and the protection of green oil, so as to reduce the volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

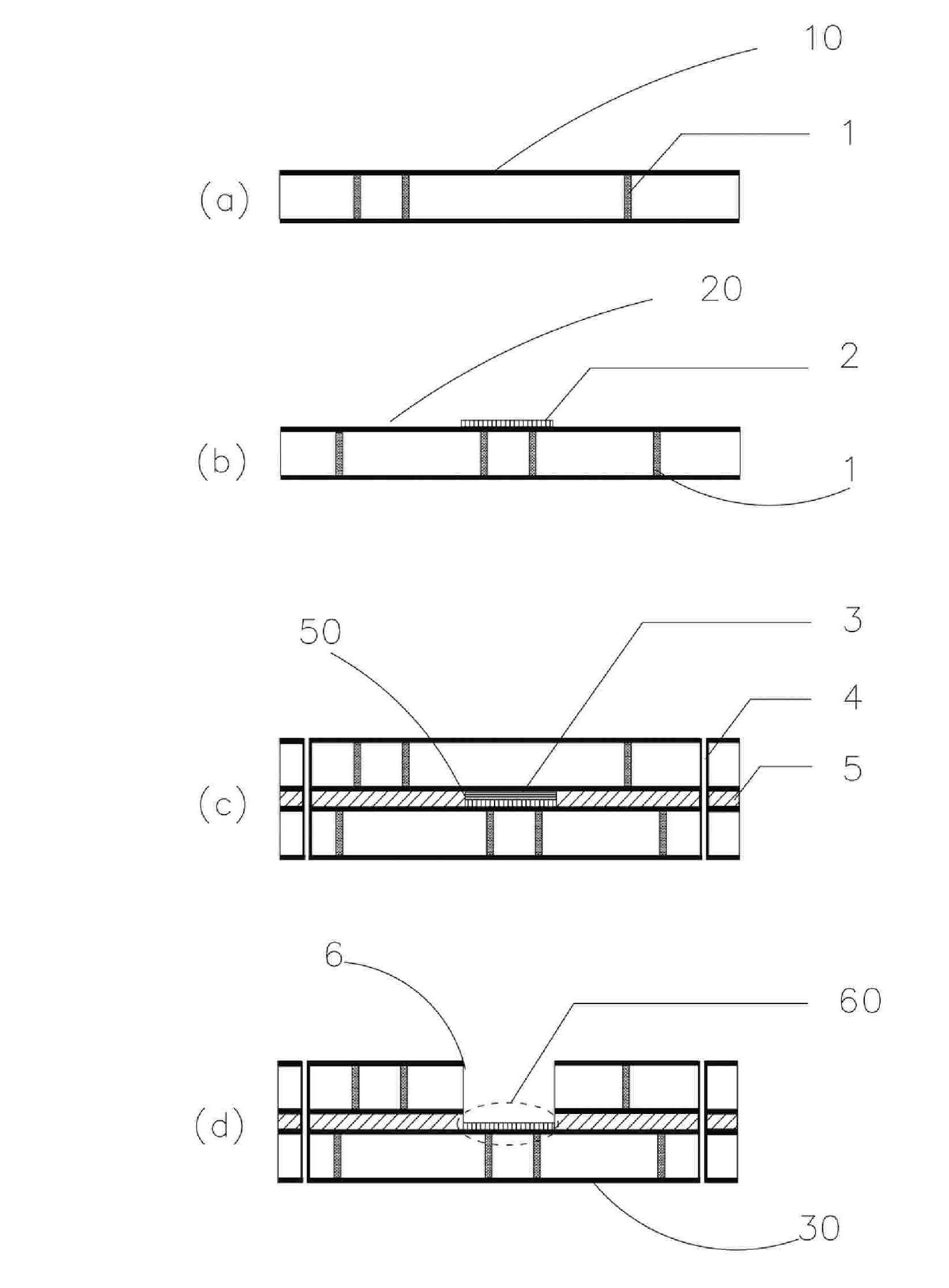

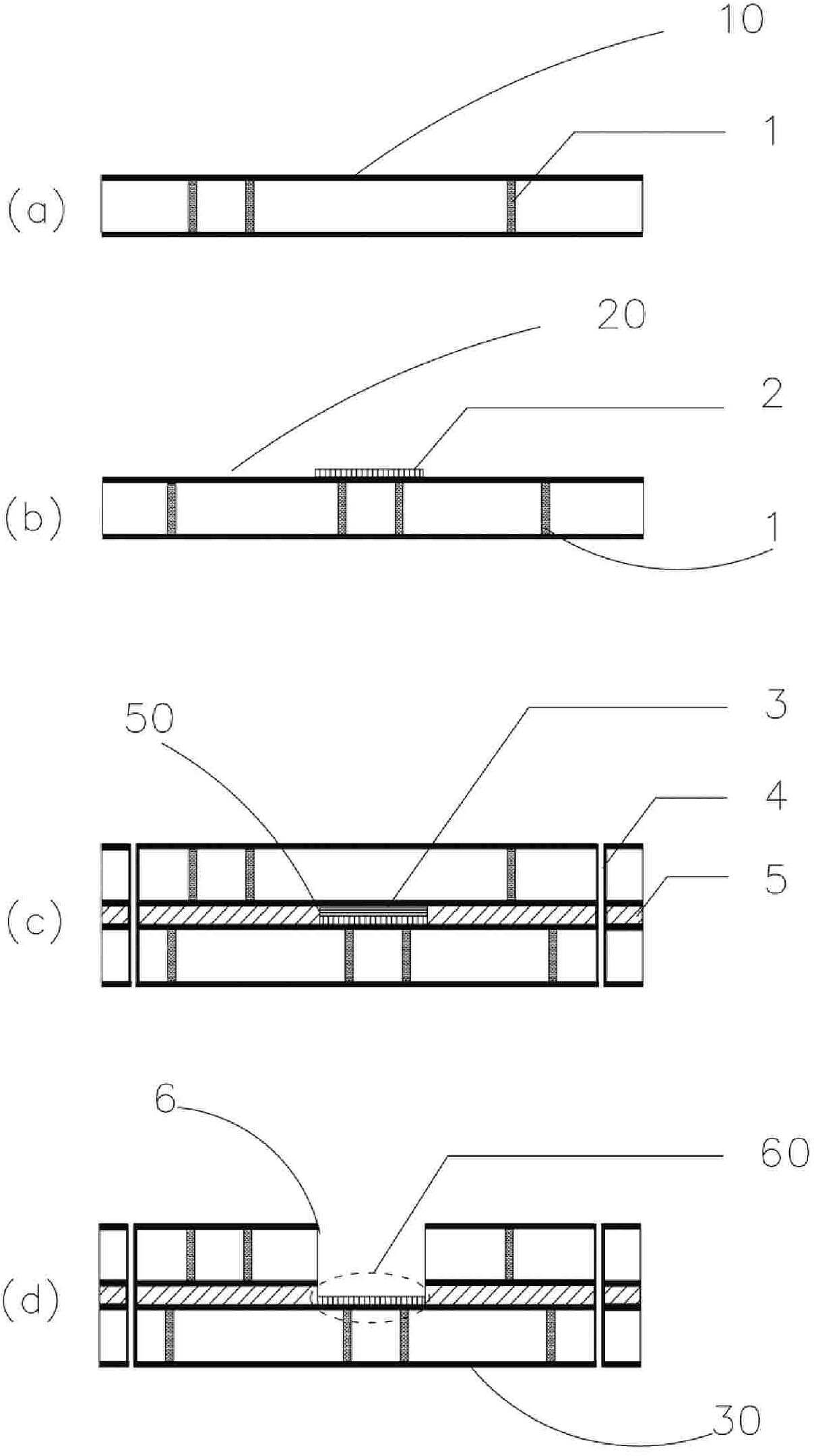

[0027] Please also refer to figure 1 , the present invention mainly utilizes the double pressing method to make the PCB board 30 with the stepped groove 6, which mainly includes the following steps: preparing the daughter boards 10 and 20, and making positioning holes (not shown) on the edge of the board; and preparing the mother board 30.

[0028] Please also refer to figure 1 (a), the sub-board 10 is a patterned laminated structure with through holes 1 drilled thereon, and a circuit (not shown) is formed in the sub-board 10 . The fabrication method of sub-board A mainly includes: inner layer fabrication, lamination, drilling, de-drilling, copper sinking, electroplating, plug hole, micro-etching, external drawing (outer layer image formation), and external etching (outer layer image etching) ) and other process steps. The sub-board 10 can be prepared by using the method for preparing a PCB board in the prior art. The inner layer fabrication includes forming circuits on ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com