Reduction mechanism

A deceleration mechanism and speed technology, applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problems of complexity, low efficiency, high overall height, etc., and achieve the effect of simple and compact structure and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

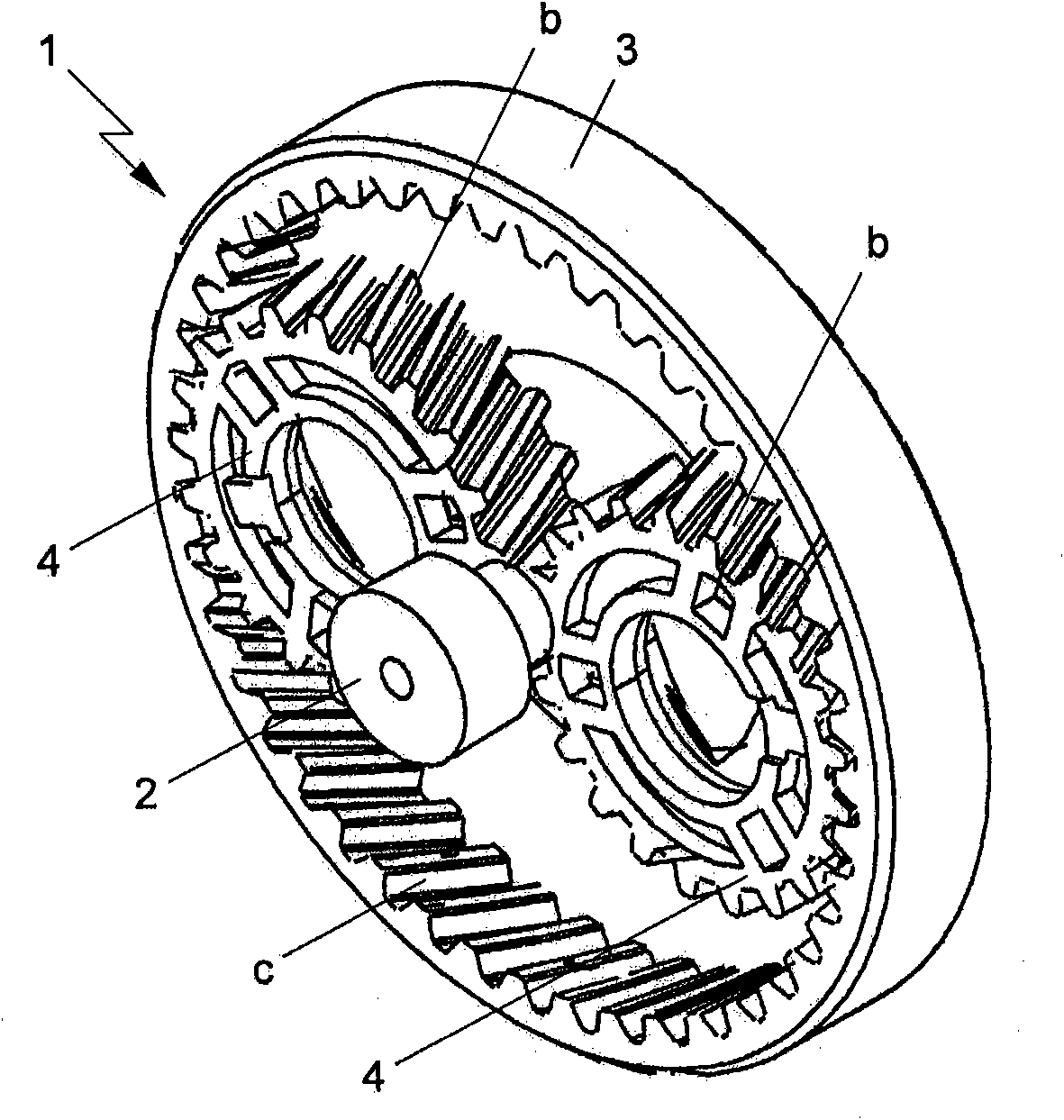

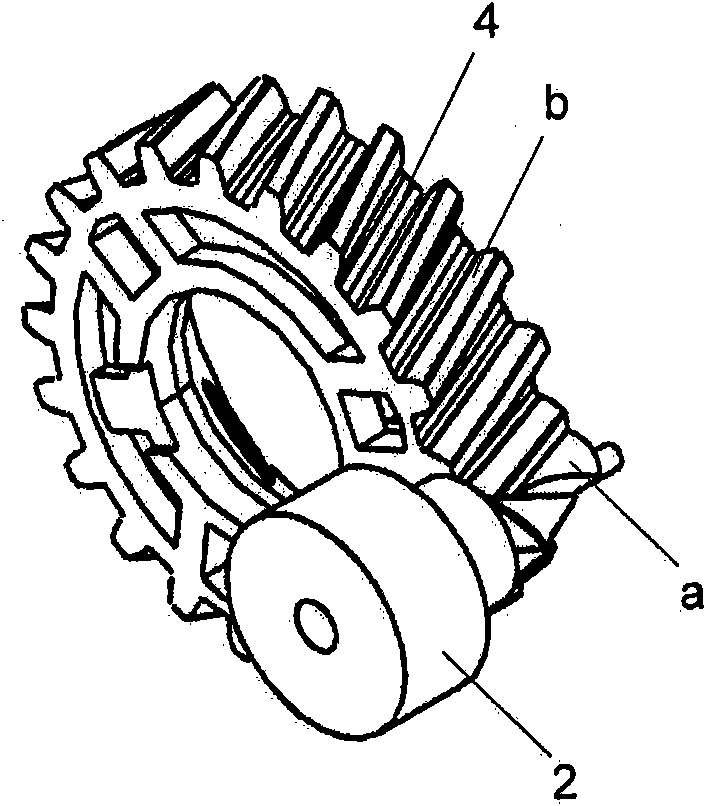

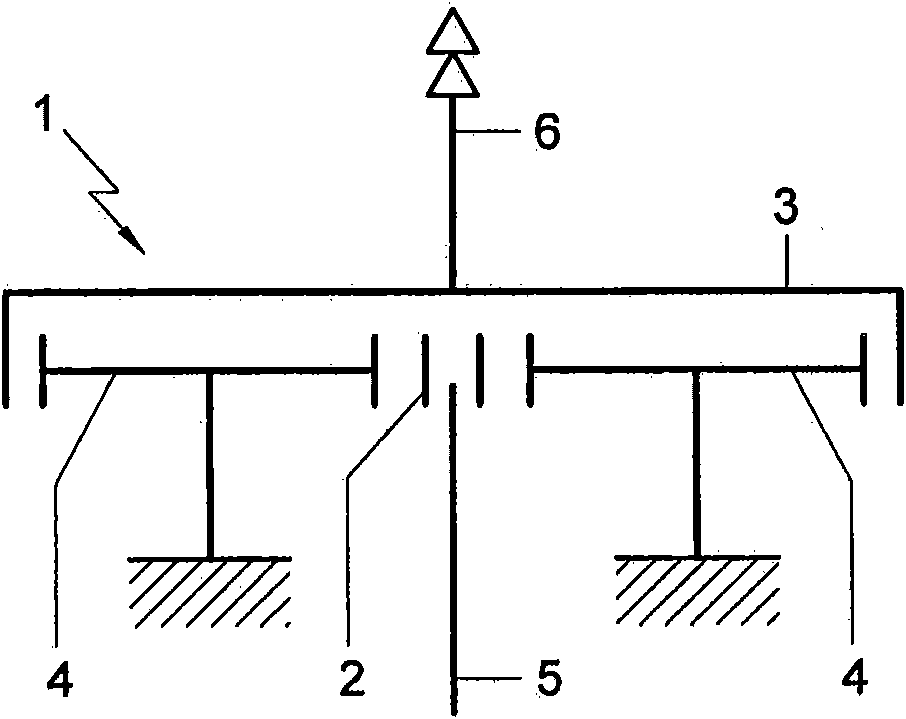

[0031] figure 1 A reduction mechanism according to the invention is shown. The reduction mechanism 1 includes an input gear 2 provided with involute external teeth a. The input gear 2 is provided with involute external teeth b, such as figure 2 shown. exist figure 2 In the exemplary embodiment, the input gear 2 is designed with two teeth.

[0032] In addition, the reduction mechanism 1 further includes an output gear 3 provided with involute internal teeth c. In use, the speed of the output gear 3 is lower than the speed of the input gear 2 . The speed is reduced according to the transmission ratio of the reduction mechanism.

[0033] in addition, figure 1 The reduction mechanism 1 in the exemplary embodiment also includes two intermediate gears 4 arranged symmetrically with respect to the input gear 2 . Each intermediate gear 4 is provided with external teeth b and cooperates with both the input gear 2 and the output gear 3 .

[0034] The input gear 2 is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com