Membrane isolating type oil tank

A membrane isolation and oil tank technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of respiratory loss, environmental protection, safety, quality, etc., and achieve the effects of protecting the environment, ensuring safety, and eliminating oil and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

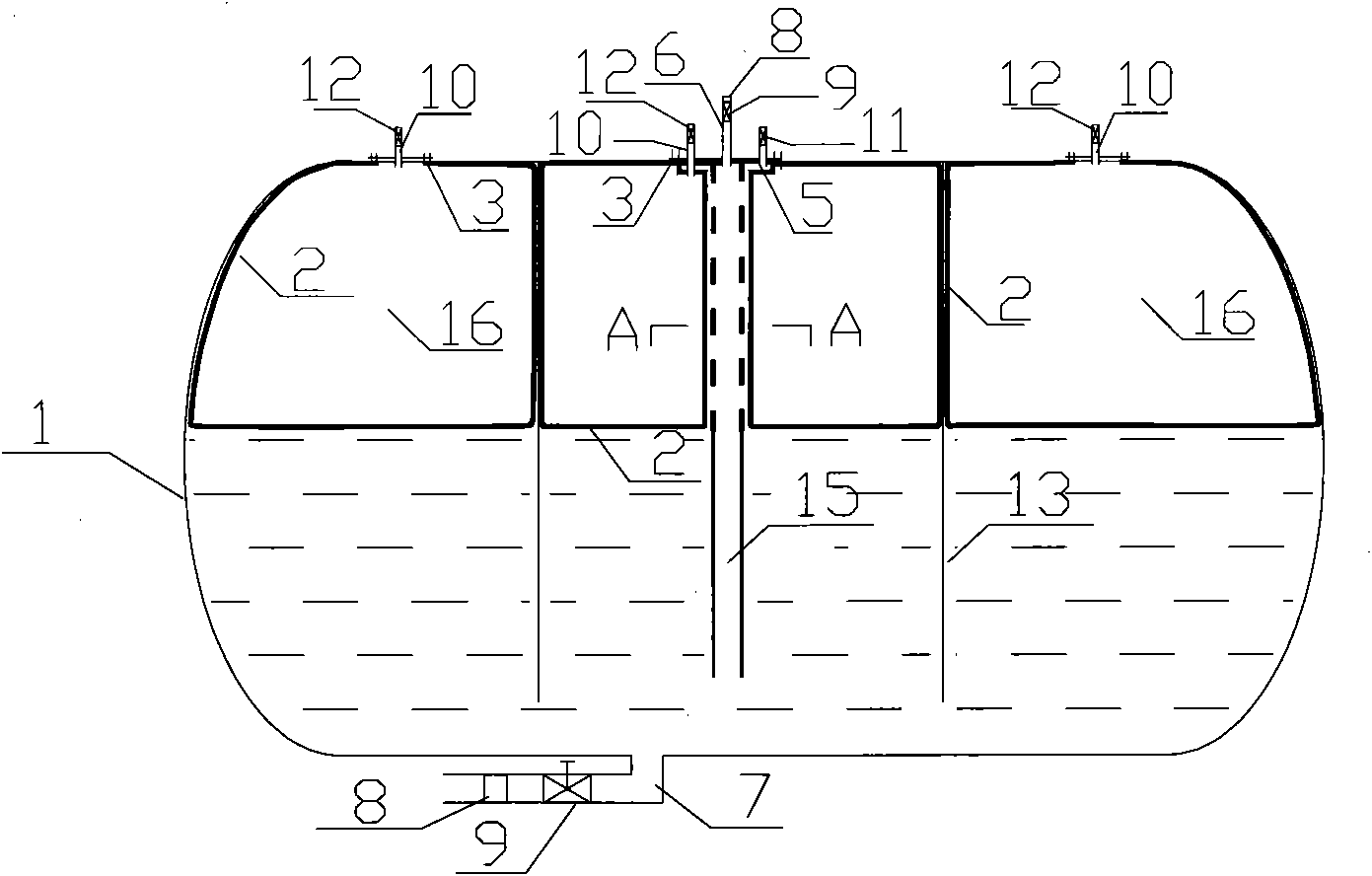

[0036] Implementation Mode 1: Top-loaded air bag type oil tank

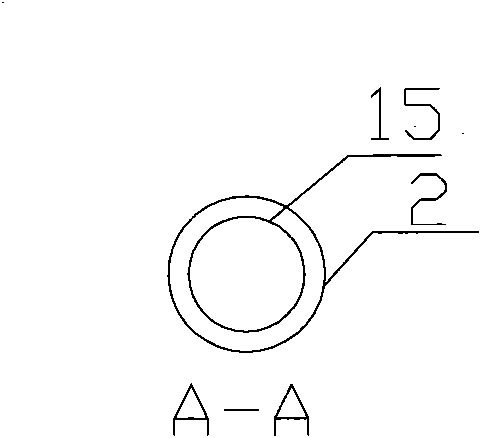

[0037] Such as Figure 2a As shown, it is a structural schematic diagram of a top-loaded air bag type oil tank according to an embodiment of the present invention. The membrane-isolated oil tank includes a tank body 1, an oil inlet pipe 6, an oil outlet pipe 7 and a breathing pipe 10 located on the tank body 1, and at least one wave-proof partition 13 perpendicular to the oil surface is provided in the tank body 1 , Both sides of the wave-proof bulkhead 13 are provided with an air bag 16 formed by the membrane 2 for isolating oil and air. In this embodiment, there are three airbags 16 separated by two anti-wave baffles 13, and the anti-wave baffles 13 have a certain distance from the bottom of the tank body 1 to facilitate oil circulation. The anti-wave partition 13 is connected with the top and both sides of the tank body 1, and is not completely sealed, leaving a certain gap, which is beneficial to the circul...

Embodiment approach 2

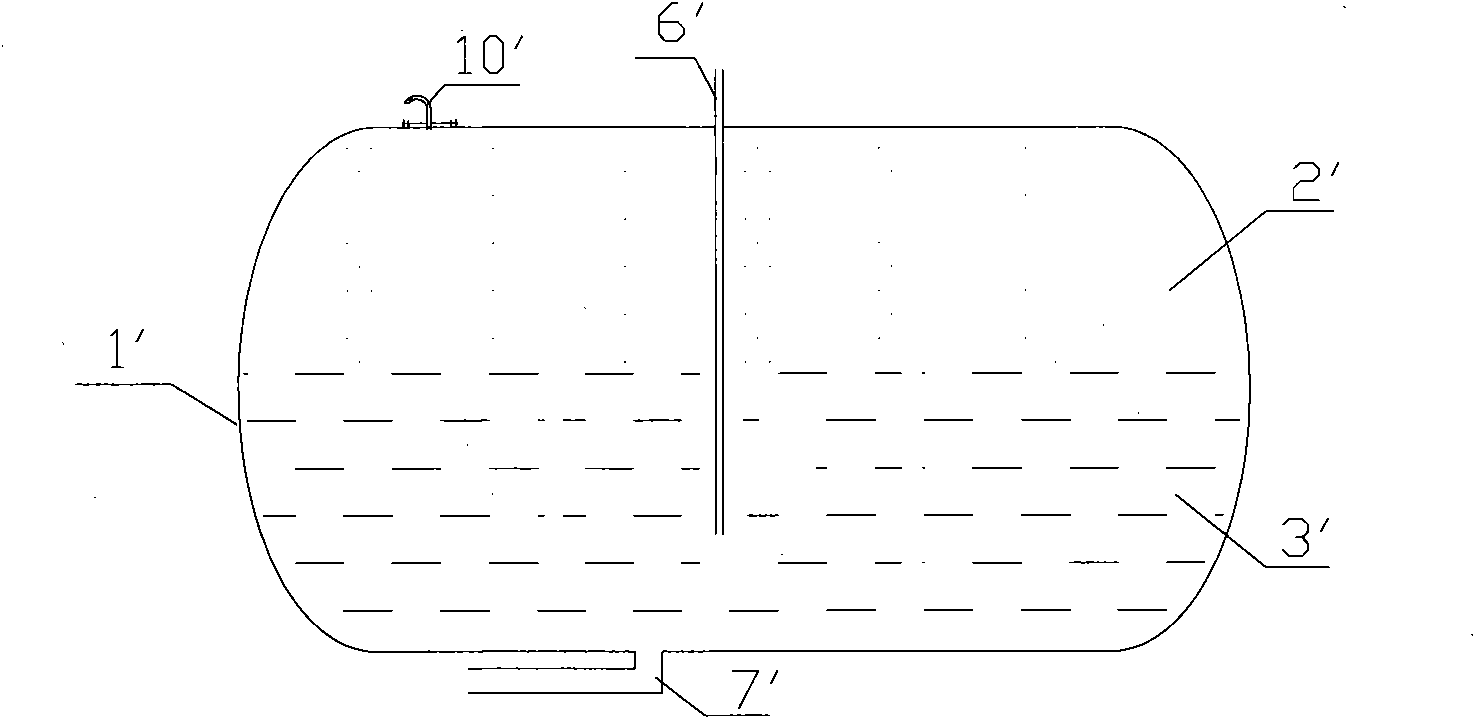

[0046] Embodiment 2: Bottom-loaded oil-pneumatic bag type oil tank

[0047] Such as image 3 As shown in FIG. 2 , it is a structural schematic diagram of the second embodiment of the present invention. The oil inlet pipe 6 is located at the bottom of the tank body 1 and can share a pipeline with the oil outlet pipe 7 . Other features of the second embodiment are the same as those of the first embodiment, and will not be repeated here.

Embodiment approach 3

[0048] Embodiment 3: Top-loaded oil bladder type oil tank

[0049] Such as Figure 4 , is a structural schematic diagram of the top-loaded oil bag type oil tank according to the third embodiment of the present invention. The membrane-isolated oil tank includes a tank body 1, an oil inlet pipe 6, an oil outlet pipe 7 and a breathing pipe 10 located on the tank body 1, and at least one wave-proof partition 13 perpendicular to the oil surface is provided in the tank body 1 , Both sides of the wave-proof baffle 13 are provided with oil pockets 17 formed by the membrane 2 for isolating oil and air. In this embodiment, there is an oil bag 17, and the anti-wave partition 13 has a certain distance from the bottom of the tank body 1 to facilitate the passage of the oil bag 17 and oil. The anti-wave partition 13 is connected with the top and both sides of the tank body 1, and is not completely sealed, leaving a certain gap, which is beneficial to the circulation of gas.

[0050] A pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com