Ultra-dispersion agent for filling modification of polymer materials and preparation method thereof

A polymer material and hyperdispersant technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of complex preparation process and inability to use directly, and achieve simple preparation method, prevention of aggregation, and difficulty in analysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

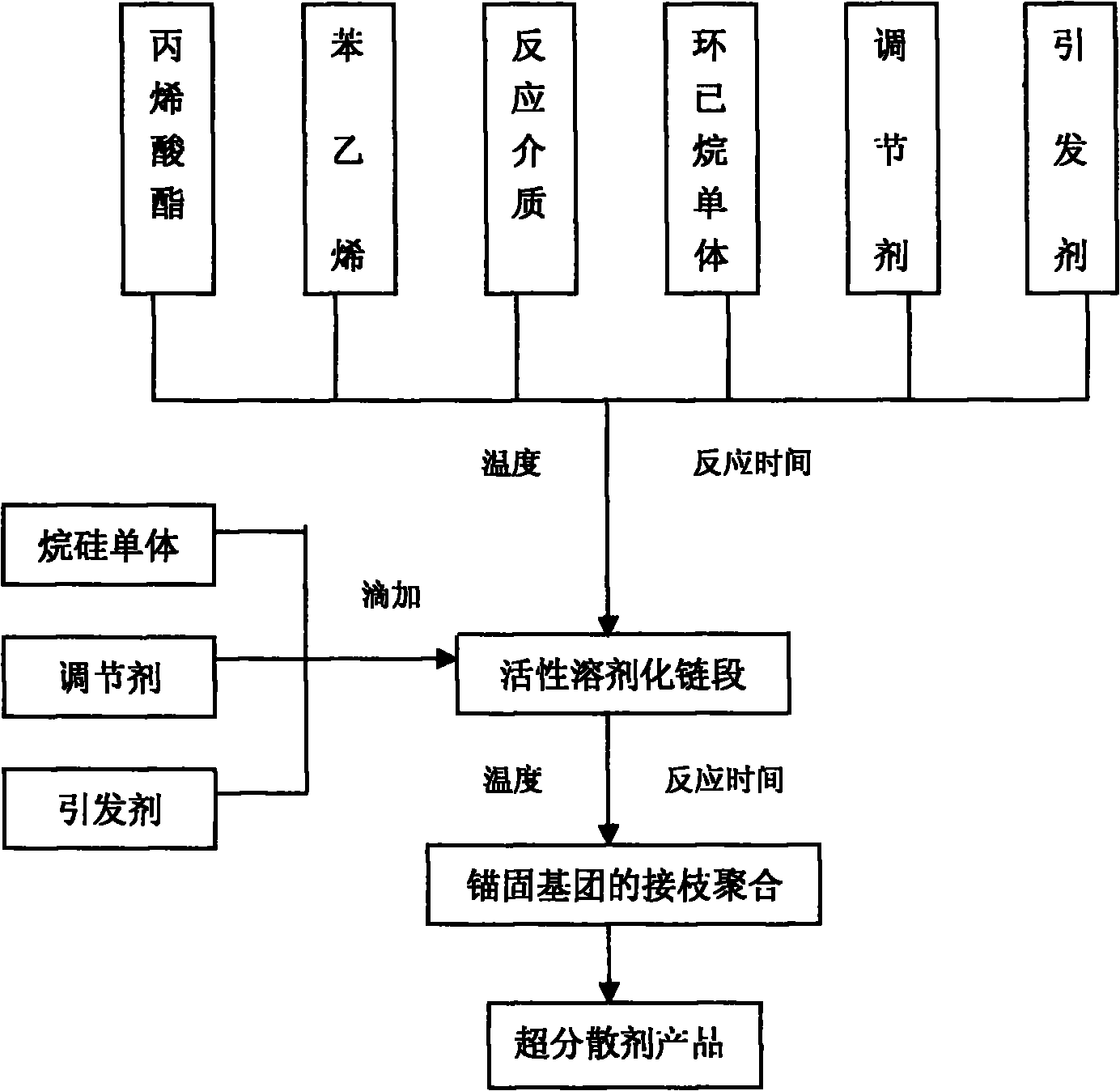

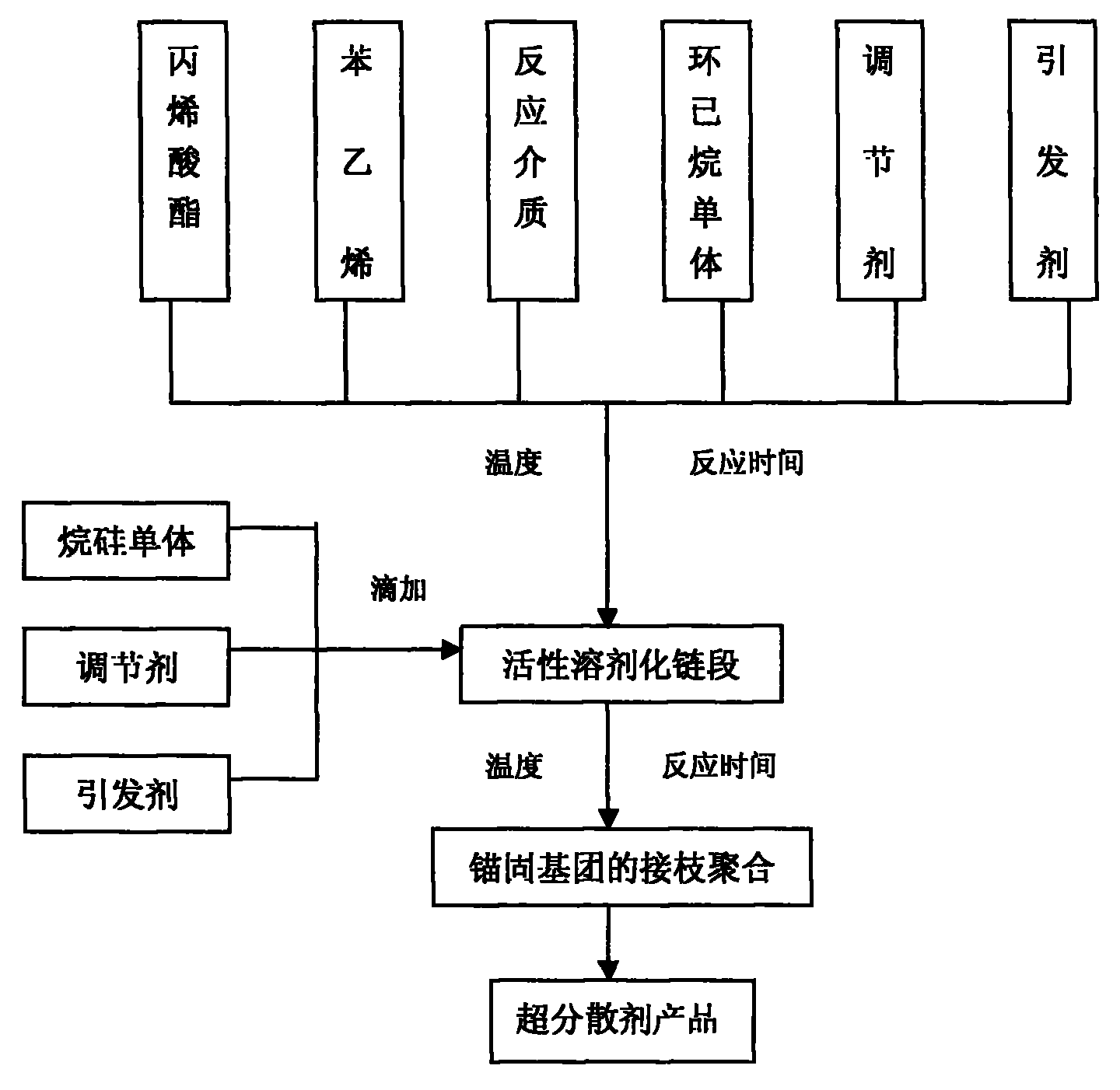

Method used

Image

Examples

Embodiment 1

[0023] a. Synthesis of active solvation segments:

[0024] 80% of butyl acrylate, 10% of styrene, and 10% of cyclohexane; add the corresponding regulator, initiator and reaction medium, the regulator is 0.3% of dodecanethiol, and the initiator of azobisisobutyronitrile is 1%. Reaction medium liquid paraffin 150%. Put each material into the reactor according to the above proportions, control the reaction temperature to be 70 degrees, the stirring speed is 400 revolutions per minute, and the reaction time is 4 hours; when the measured conversion rate reaches 95%, the material is discharged; it is prepared into an active solvation segment.

[0025] b. Graft polymerization of anchoring groups:

[0026] In the reactor, pour 90% of the active solvated segment prepared in the previous stage, 10% of γ-(methacryloyloxy)propyltrimethoxysilane, 0.5% of initiator azobisisobutyronitrile, regulator Dodecanethiol 0.2% mixture is gradually added dropwise to the reactor, the temperature is c...

Embodiment 2

[0028] a. Synthesis of active solvation segments:

[0029] 50% of butyl acrylate, 25% of styrene, and 25% of cyclohexane; add the corresponding regulator, initiator and reaction medium, 0.3% of dodecanethiol as regulator, 1% of azobisisobutyronitrile as initiator, Reaction medium liquid paraffin 150%. Put each material into the reactor according to the above proportions, control the reaction temperature to be 70 degrees, the stirring speed is 400 revolutions per minute, and the reaction time is 4 hours; when the measured conversion rate reaches 95%, the material is discharged; it is prepared into an active solvation segment.

[0030] b. Graft polymerization of anchoring groups:

[0031] Pour 90% of the active solvated segment prepared in the previous stage into the reactor, a mixture of 10% vinyltriethoxysilane, 0.5% initiator azobisisobutyronitrile, and 0.2% dodecanethiol regulator Gradually drop it into the reactor, control the temperature to 70 degrees, stir at 500 rpm, a...

Embodiment 3

[0033] a. Synthesis of active solvation segments:

[0034] 80% of butyl acrylate, 10% of styrene, and 10% of cyclohexane; add the corresponding regulator, initiator and reaction medium, the regulator is 0.3% of dodecanethiol, and the initiator of azobisisobutyronitrile is 1%. Reaction medium liquid paraffin 150%. Put each material into the reactor according to the above proportions, control the reaction temperature to be 70 degrees, the stirring speed is 400 revolutions per minute, and the reaction time is 4 hours; when the measured conversion rate reaches 95%, the material is discharged; it is prepared into an active solvation segment.

[0035] b. Graft polymerization of anchoring groups:

[0036] Pour 90% of the active solvated segment prepared in the previous stage into the reactor, a mixture of 20% vinyltriethoxysilane, 0.5% initiator azobisisobutyronitrile, and 0.2% regulator dodecanethiol Gradually drop it into the reactor, control the temperature to 70 degrees, stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com