Method for preparing target material

A technology of target material and base material, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of poor product uniformity, complicated process, excessive grain size, etc., and achieve good uniformity and process Simple, small grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

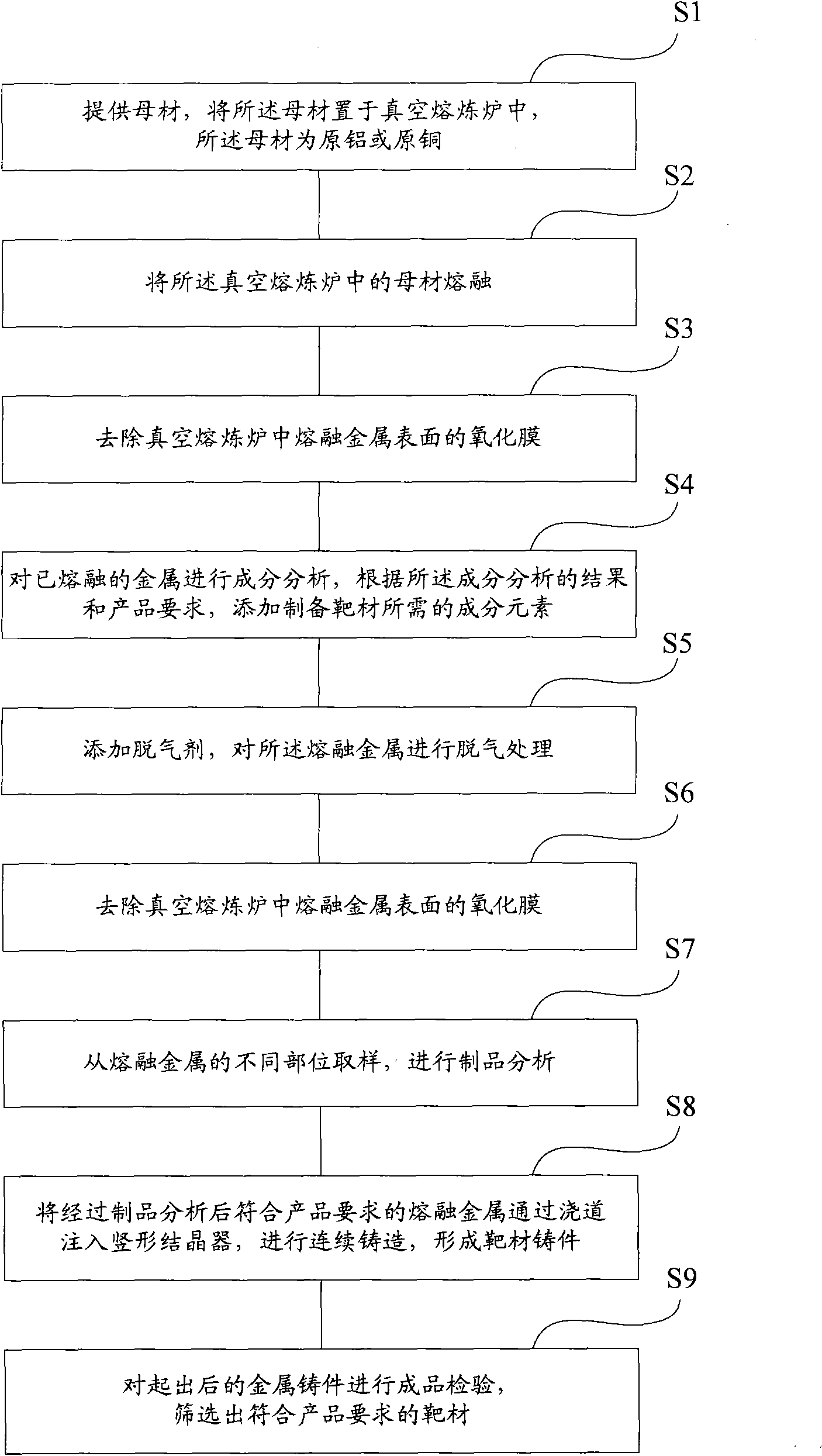

[0021] The inventors of the present invention found that when preparing target materials, the four-stage refining method including three-layer liquid electrolysis, segregation method, room temperature ionic liquid electrolysis and zone smelting method was used in the past to prepare ultra-pure aluminum or ultra-pure copper , the process is complicated, the processing time is long, the work efficiency is low, and the prepared ultra-pure aluminum or ultra-pure copper has problems such as poor uniformity and coarse grains.

[0022] In view of this, the inventors of the present invention conceived to improve the purification method and adopt a combination of vacuum melting and continuous casting with fewer procedures and higher efficiency to prepare the target.

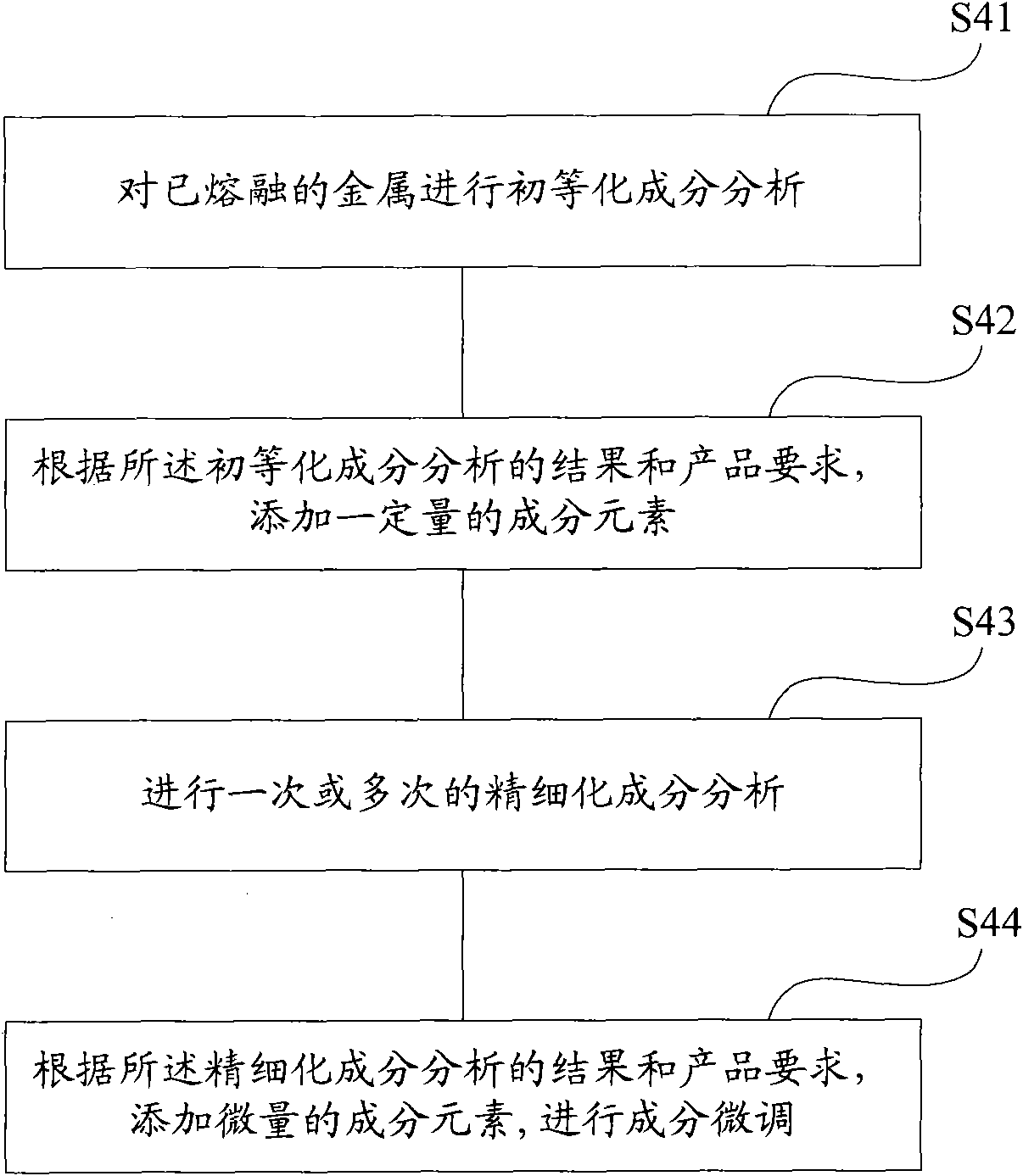

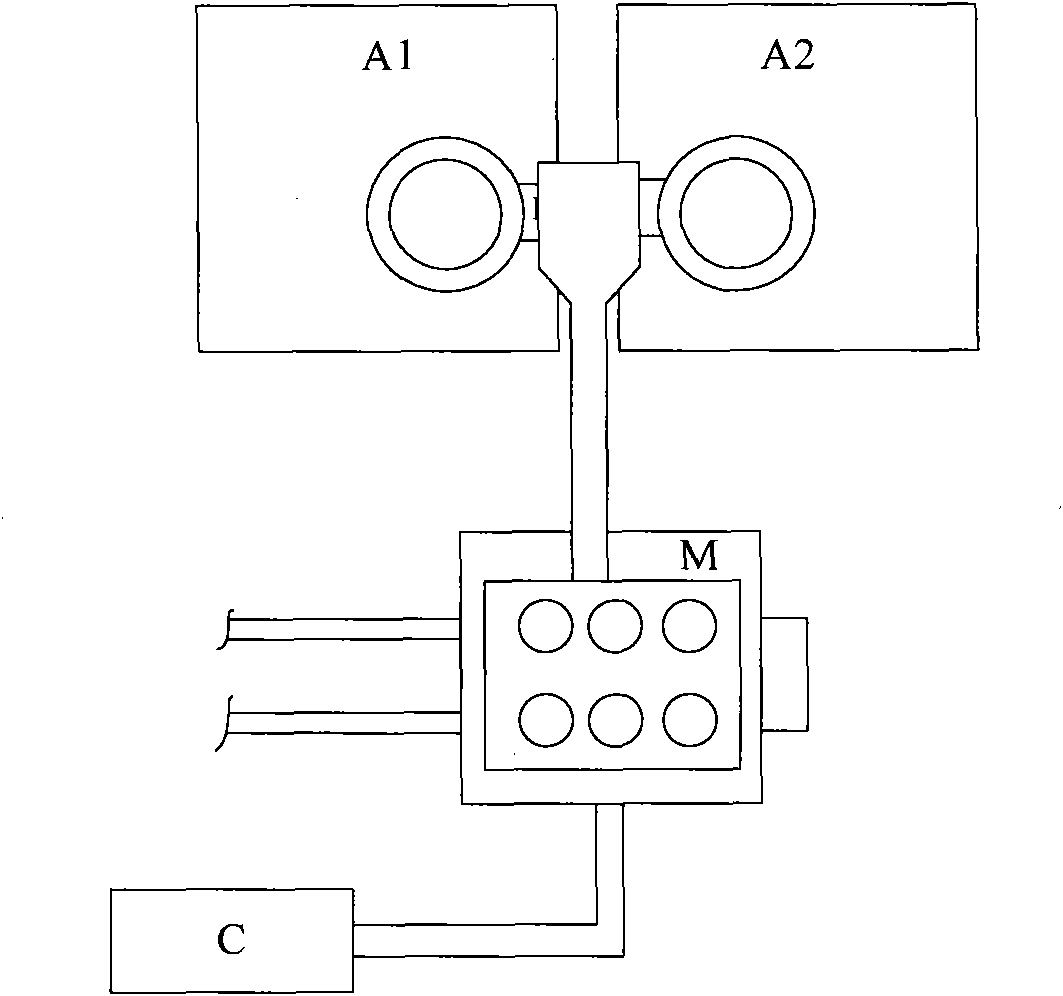

[0023] The invention provides a method for preparing a target, comprising: providing a base material, and placing the base material in a vacuum melting furnace, the base material being primary aluminum or copper; placing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com