Liquid reservoir and manufacture method thereof as well as air-conditioner

A manufacturing method and technology of a liquid accumulator, which are applied in air-conditioning systems, refrigerators, heating methods, etc., can solve the problems of high temperature damage of red copper coating, affecting welding effect, surface coating peeling, etc., achieving good welding effect, short heating time, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

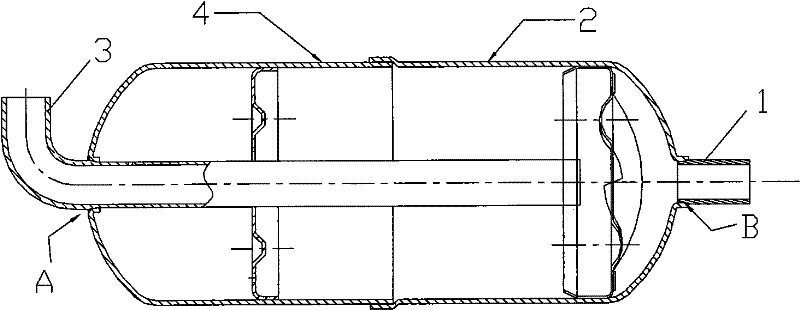

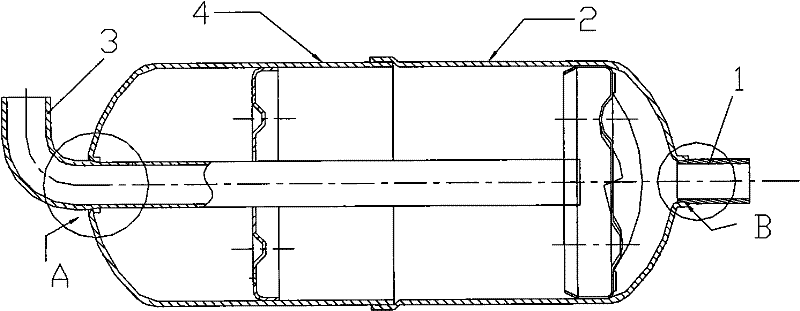

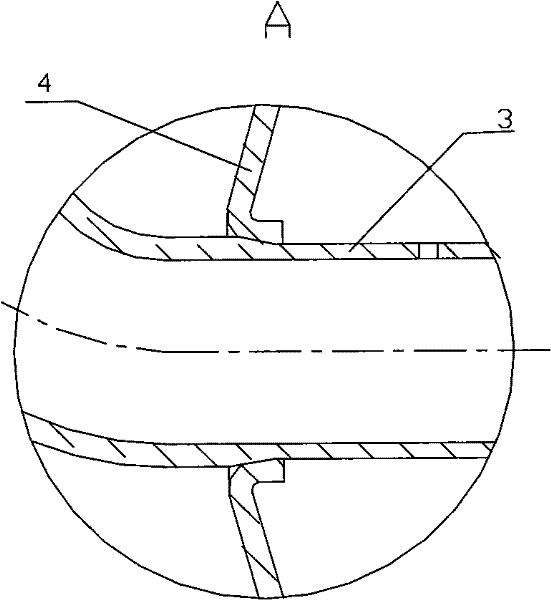

[0051] like Figure 2a , 2b , shown in 2c, according to a kind of accumulator of the first embodiment of the present invention, comprises: air inlet and outlet pipe; Cylinder, it has welding hole 15 (as Figure 16a , 16b, 17a, 17b). The welding hole 15 is connected with the air inlet and outlet pipes by resistance welding, that is, the welding places A and B are connected by resistance welding. The cylinder body includes an upper cylinder body 2 and a lower cylinder body 4, and the upper cylinder body 2 and the lower cylinder body 4 are welded by carbon dioxide shielded welding or argon arc welding. The air inlet and outlet pipes can be steel pipes coated with copper on the inner and outer surfaces, so as to be connected with the air-conditioning pipelines. According to specific conditions, the air inlet and outlet pipes can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com