Method and device for detecting precision wafer based on parallel optical flat splitting polarized beam and phase-shifting interferometry

A parallel flat crystal, phase-shift interference technology, applied in measurement devices, optical devices, analysis of materials, etc., can solve the problems of large system error, easy to be affected by external interference, low measurement accuracy, etc., to achieve low system error and simplified optical path. The effect of high design and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

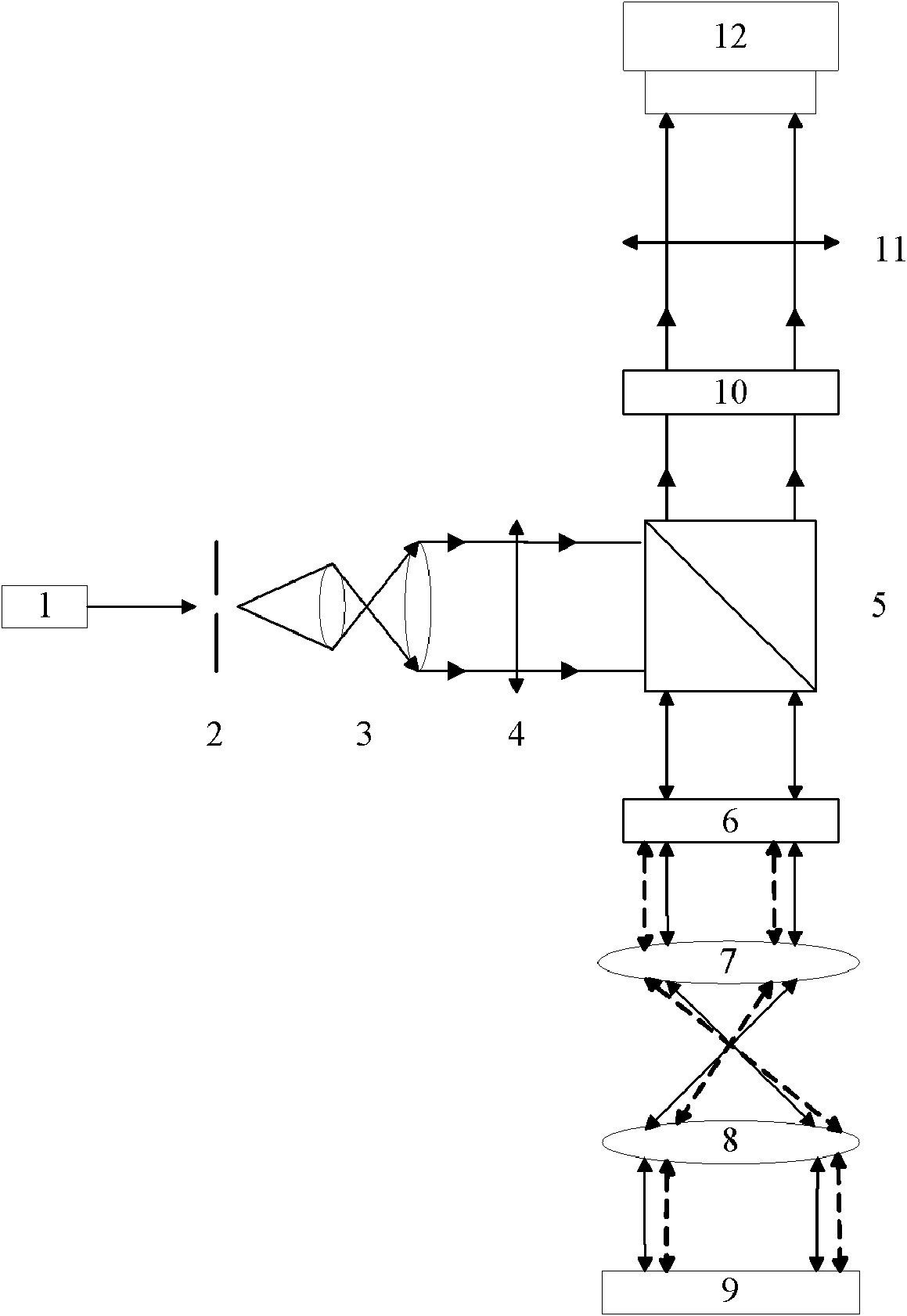

[0018] see figure 1 , is a structural schematic diagram of the optical path system of a preferred embodiment of a precision wafer inspection device based on parallel planar split-polarized beams and phase-shift interferometry according to the present invention. The detection device includes a light source 1, a spatial filter 2, a beam expander 3, a polarizer 4, a depolarization beam splitter prism 5, a parallel flat crystal 6, a first convex lens 7, a second convex lens 8, and a 1 / 4 wave plate 10. Analyzer 11 and CCD imaging device 12. figure 1 The surface 9 of the measured object is also indicated in .

[0019] The light source 1, the spatial filter 2, the beam expander 3, and the polarizer 4 are arranged in sequence. The depolarization beam splitting prism 5, the parallel flat crystal 6, the first convex lens 7, the second convex lens 8 and the surface 9 of the measured object are arranged in sequence. The depolarizing beam splitting prism 5, 1 / 4 wave plate 10, analyzer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com