A reverse light scattering transparent ceramic capable of realizing optical path off-on and its application

A technology of transparent ceramics and light scattering, which is applied in the field of optical communication, can solve problems that do not involve electronically controlled light scattering effects, and achieve the effects of simplifying optical path design, reducing system cost, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

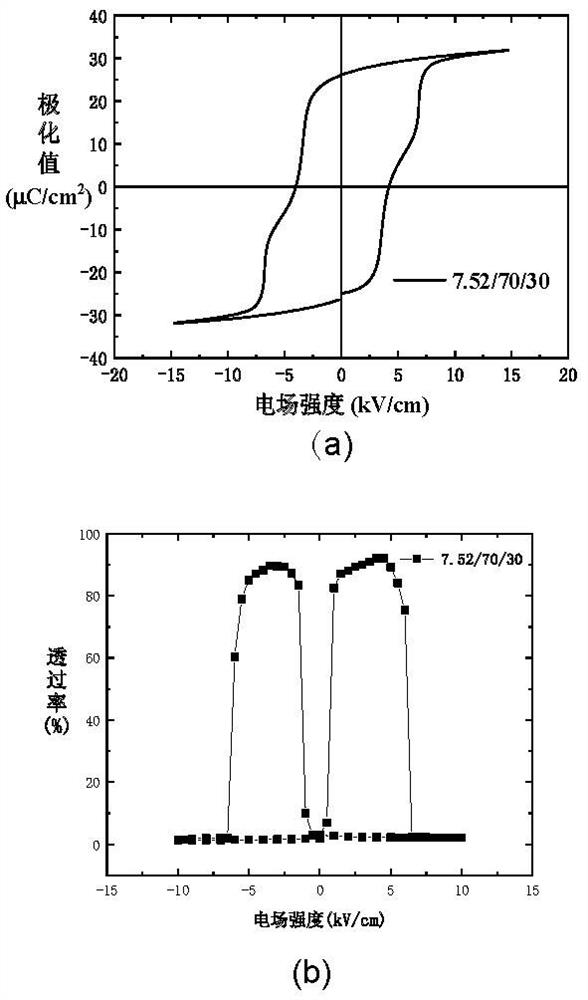

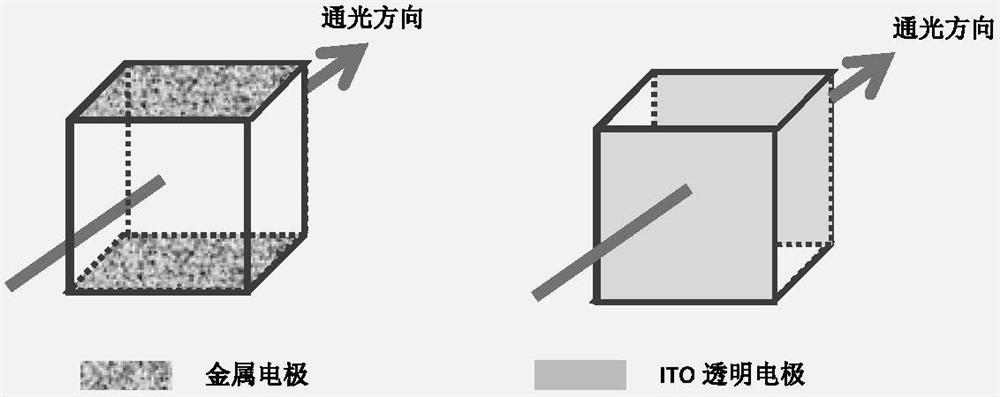

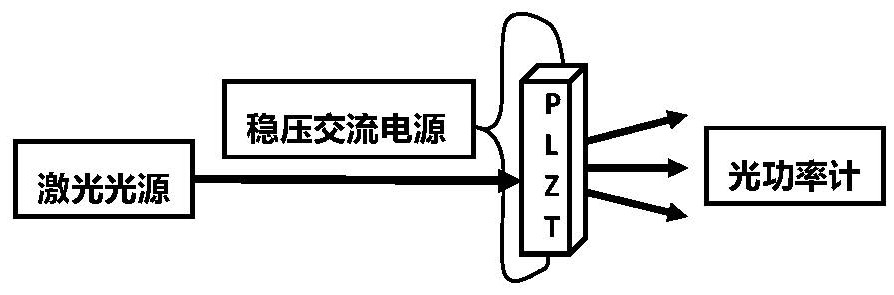

Embodiment 1

[0039] According to Pb 1-x La x (Zr y Ti 1-y ) 1-x / 4 o 3 , where x=0.0752, y=0.70 ingredients, add 0.7 parts of absolute ethanol (ie 100g powder to add 70ml), ball mill for 5 hours, dry and sieve through 200 mesh. Add 6% PVA to granulate, press into Φ35mmx20mm cylindrical biscuit, and sinter by hot pressing with oxygen. The sintering temperature is 1280°C / 10h, the pressure is 40MP, and the oxygen flow rate is maintained at 5 liters / minute during the sintering process. After cutting, grinding, polishing and other processes, the ceramic blocks are processed into Φ35mm×1mm, 5mm×5mm×2mm ceramic sheets, and after double-sided polishing, the optical transmittance and reverse light scattering performance tests are carried out. In addition, they are also processed into 5mm×5mm The 5mm×1mm ceramic sheet was finely ground on both sides, and the ferroelectric test was carried out. The main performance parameters are shown in Table 1.

Embodiment 2

[0041] According to Pb 1-x La x (Zr y Ti 1-y ) 1-x / 4 o 3 , where x=0.0743, y=0.70 ingredients, add 0.7 parts of absolute ethanol (ie 100g powder into 70ml), ball mill for 5 hours, dry and sieve through 200 mesh. Add 6% PVA to granulate, press into Φ35mmx20mm cylindrical biscuit, and sinter by hot pressing with oxygen. The sintering temperature is 1280°C, the pressure is 40MP, the pressure is released after 10 hours of heat preservation and pressure holding, and the oxygen flow rate is kept at 5 liters / minute during the sintering process. After cutting, grinding, polishing and other processes, the ceramic blocks are processed into Φ35mm×1mm, 5mm×5mm×2mm ceramic sheets, and after double-sided polishing, the optical transmittance and reverse light scattering performance tests are carried out. In addition, they are also processed into 5mm×5mm The 5mm×1mm ceramic sheet was finely ground on both sides, and the ferroelectric test was carried out. The main performance parameters...

Embodiment 3

[0043] According to Pb 1-x La x (Zr y Ti 1-y ) 1-x / 4 o 3 , where x=0.0734, y=0.70 ingredients, add 0.7 part of absolute ethanol (ie 100g powder into 70ml), ball mill for 5 hours, dry and sieve through 200 mesh. Add 6% PVA to granulate, press into Φ35mmx20mm cylindrical biscuit, and sinter by hot pressing with oxygen. The sintering temperature is 1280°C, the pressure is 40MP, the pressure is released after 10 hours of heat preservation and pressure holding, and the oxygen flow rate is kept at 5 liters / minute during the sintering process. After cutting, grinding, polishing and other processes, the ceramic blocks are processed into Φ35mm×1mm, 5mm×5mm×2mm ceramic sheets, and after double-sided polishing, the optical transmittance and reverse light scattering performance tests are carried out. In addition, they are also processed into 5mm×5mm The 5mm×1mm ceramic sheet was finely ground on both sides, and the ferroelectric test was carried out. The main performance parameters ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com