Method for preparing phase change thermal storage-based novel energy-storing and heat-insulating mortar

A thermal insulation mortar, phase change heat storage technology, applied in the fields of building energy saving, solar energy utilization, wall insulation, and thermal storage materials, can solve the problems of limited application, easy to flow, no fixed shape, etc. Good performance and improved thermal comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

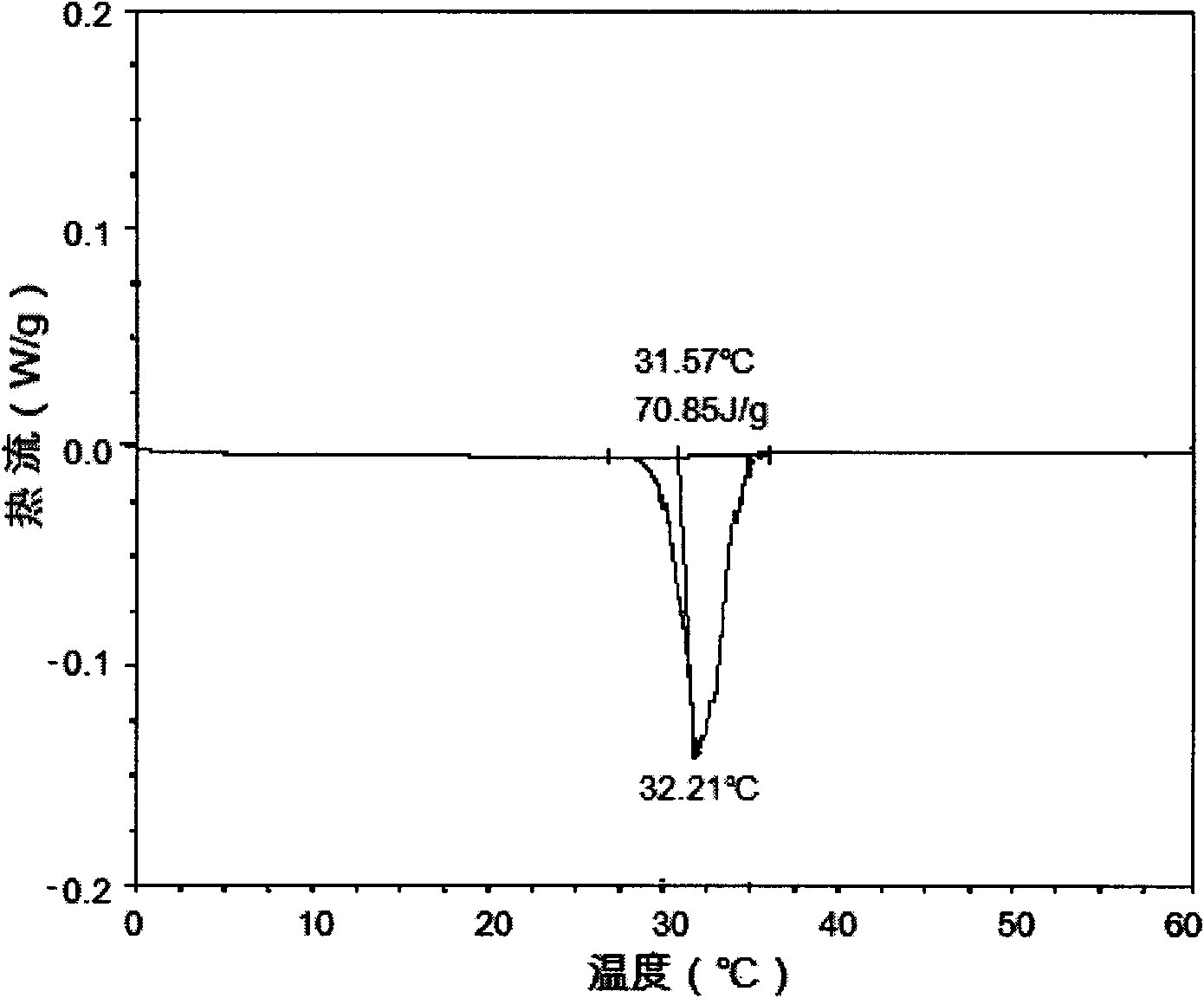

[0027] Example 1: 200g of expanded perlite particles with a particle diameter of 1mm to 3mm are subjected to high temperature drying treatment (drying time is 1 hour to 1.5 hours, and drying temperature is 105 ℃ to 110 ℃); then it is evacuated to vacuum degree The temperature is 0.1MPa~0.2MPa, the temperature is controlled at 50℃, 300g of capric acid melted into a liquid state is added, and the vacuum degree is kept at 0.1MPa~0.2MPa for 6min~8min, and then the air valve is opened to allow air to enter. At this time, the phase change material enters the expansion Inside the micropores of the perlite aggregate; cool the composite phase change material to normal temperature; after cooling, it is evacuated to a vacuum degree of 0.1 MPa to 0.2 MPa, the temperature is controlled at 80 ° C, and 150 g of paraffin wax that is melted into a liquid is added. Sealing material (melting point is 70℃), keep the vacuum degree of 0.1MPa~0.2MPa for 3min~4min, then open the air valve to let air i...

example 2

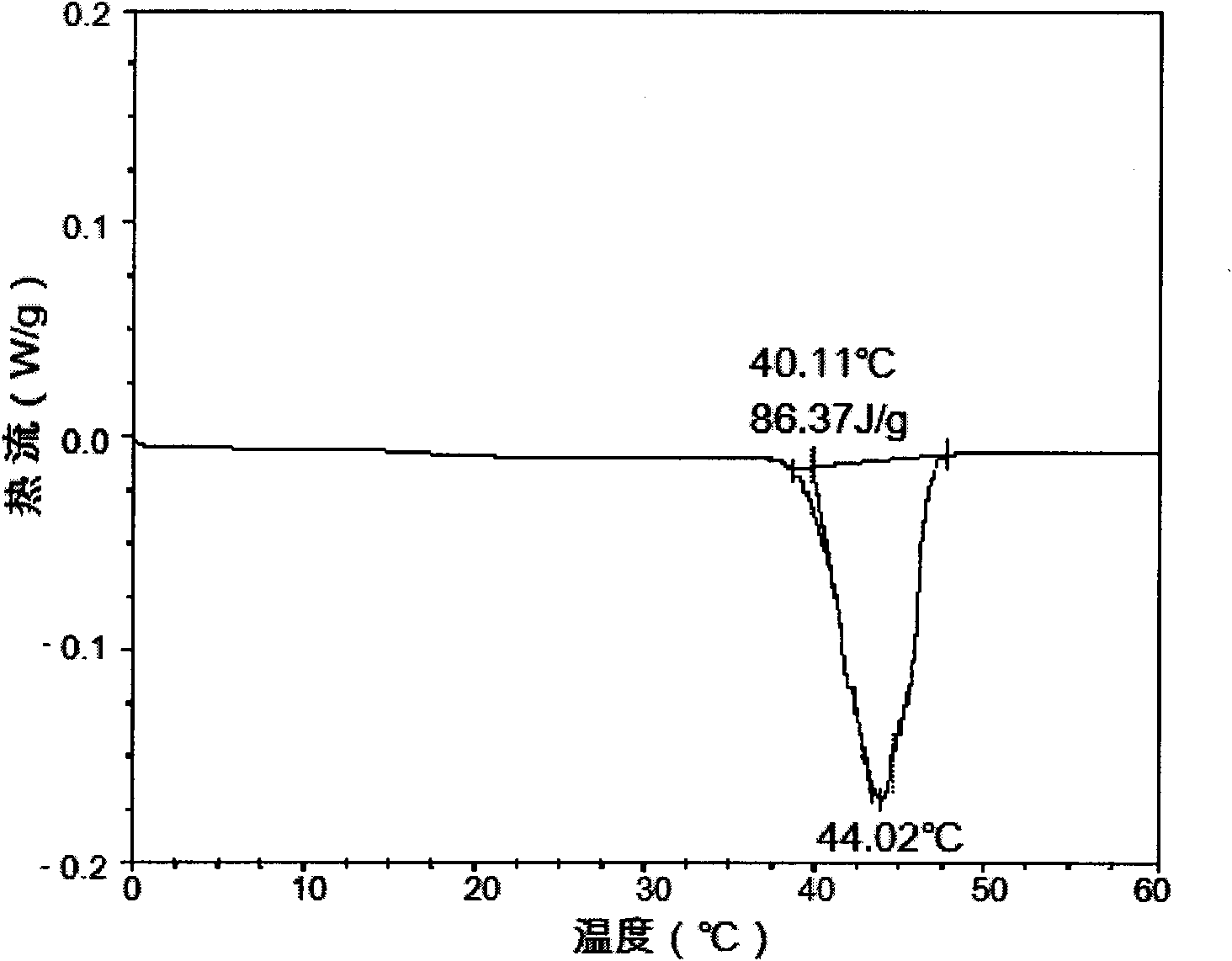

[0029] Example 2: 200g particle diameter is that the expanded perlite particle of 1mm~3mm is carried out high temperature drying treatment (drying time is 1 hour~1.5 hour, and drying temperature is 105 ℃~110 ℃); It is then evacuated to vacuum degree It is 0.1MPa~0.2MPa, the temperature is controlled at 50℃, 300g of lauric acid melted into a liquid state is added, and the vacuum degree is kept at 0.1MPa~0.2MPa for 6~8min, and then the air valve is opened to allow air to enter. At this time, the phase change material enters the expansion Inside the micropores of the perlite aggregate; cool the composite phase change material to normal temperature; after cooling, it is evacuated to a vacuum degree of 0.1 MPa to 0.2 MPa, the temperature is controlled at 80 ° C, and 150 g of paraffin wax that is melted into a liquid is added. Sealing material (melting point is 70℃), keep the vacuum degree of 0.1MPa~0.2MPa for 3min~4min, then open the air valve to let air in, at this time paraffin en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com